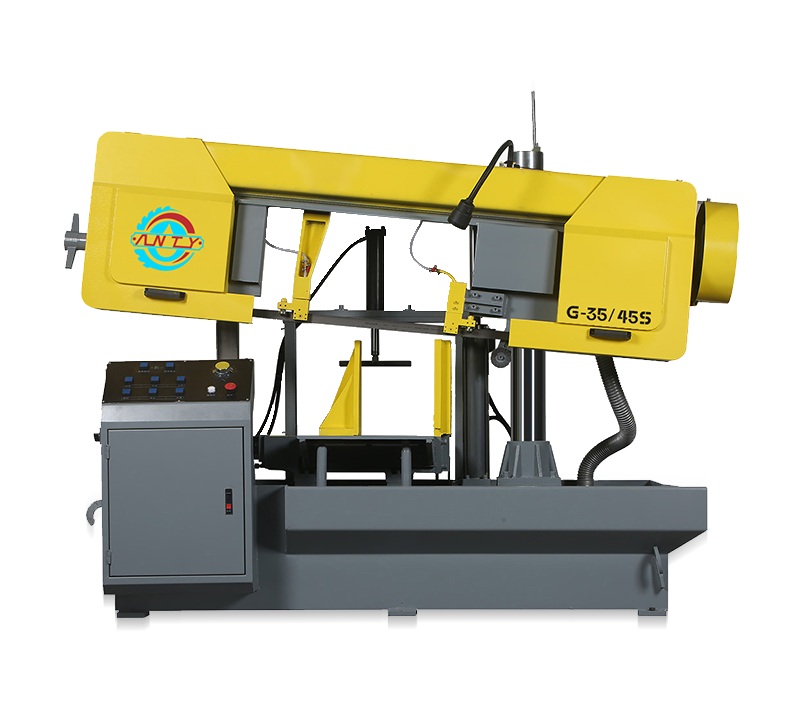

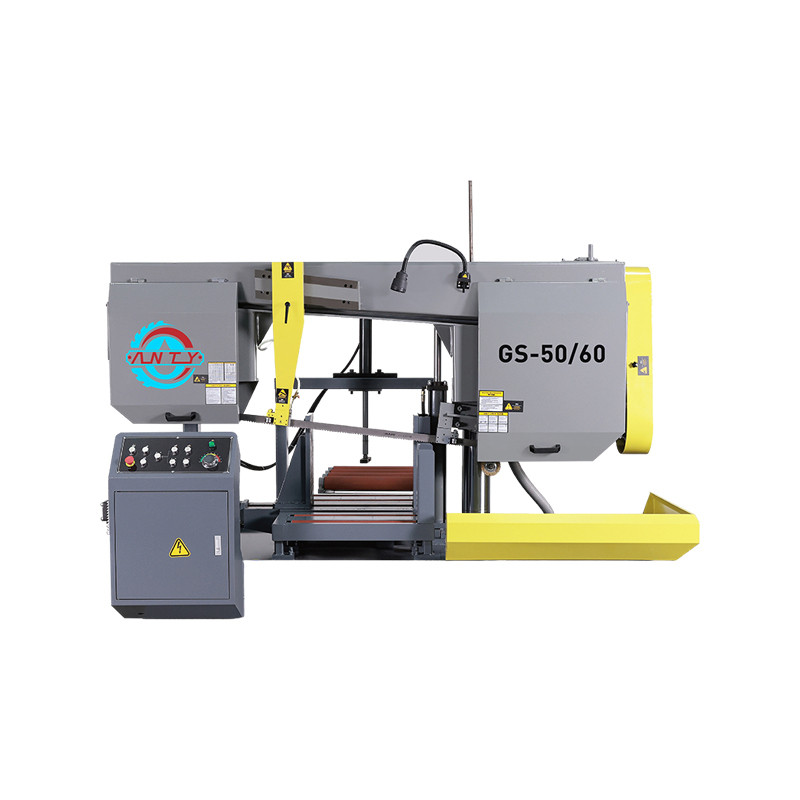

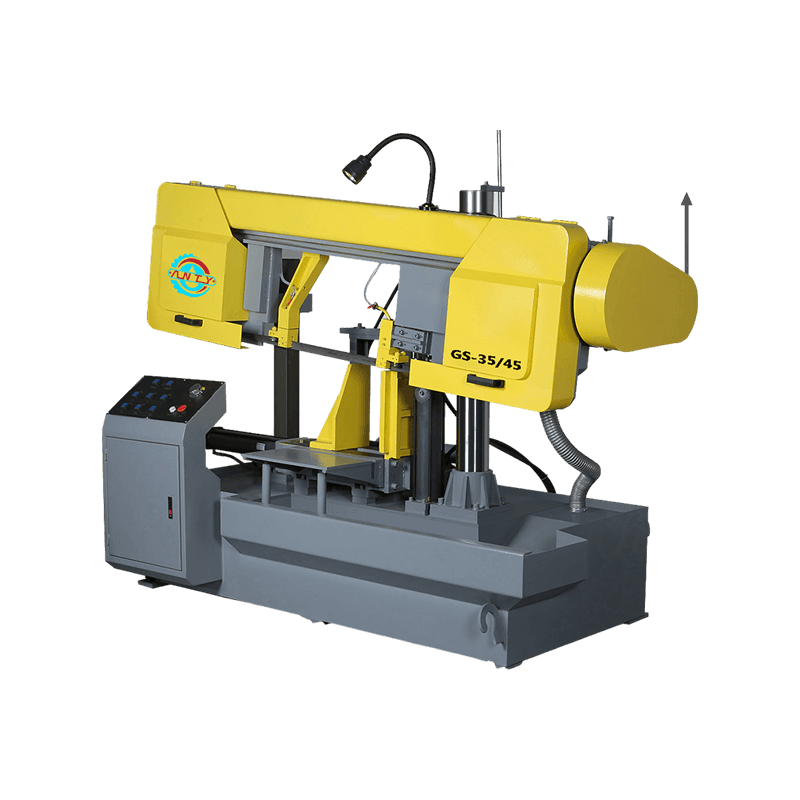

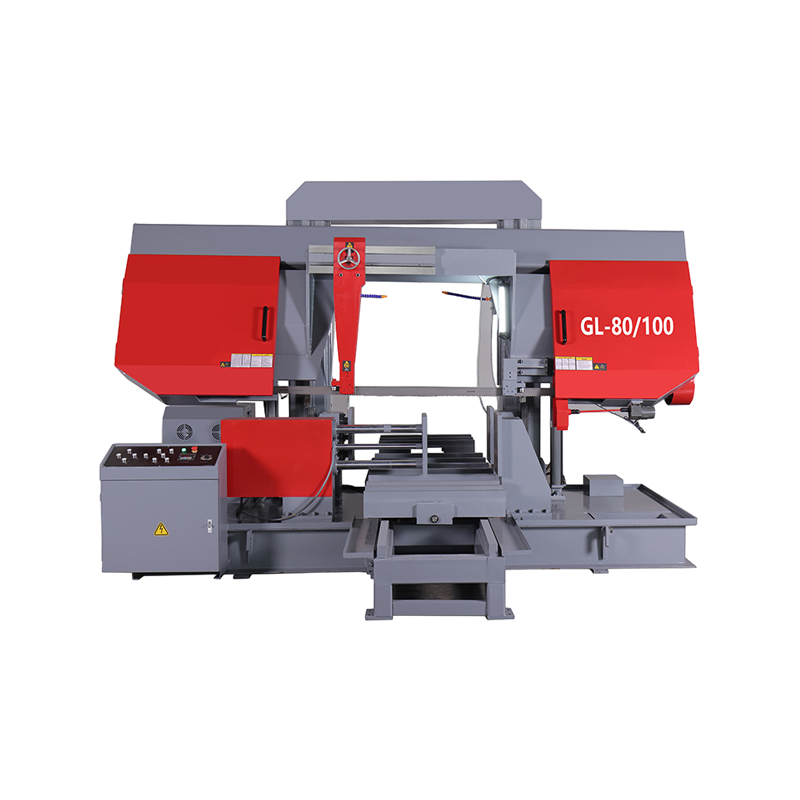

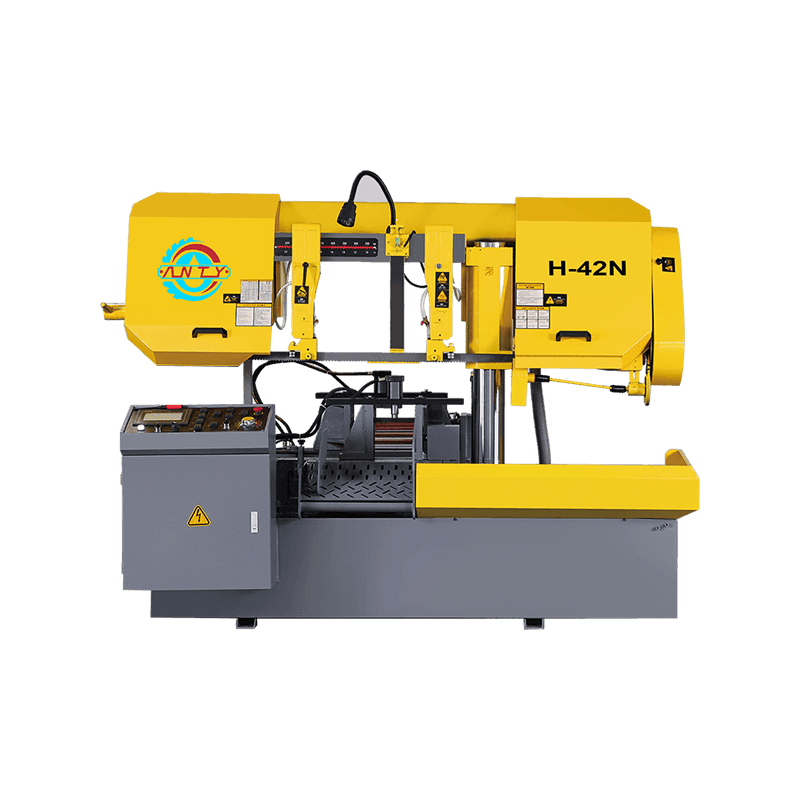

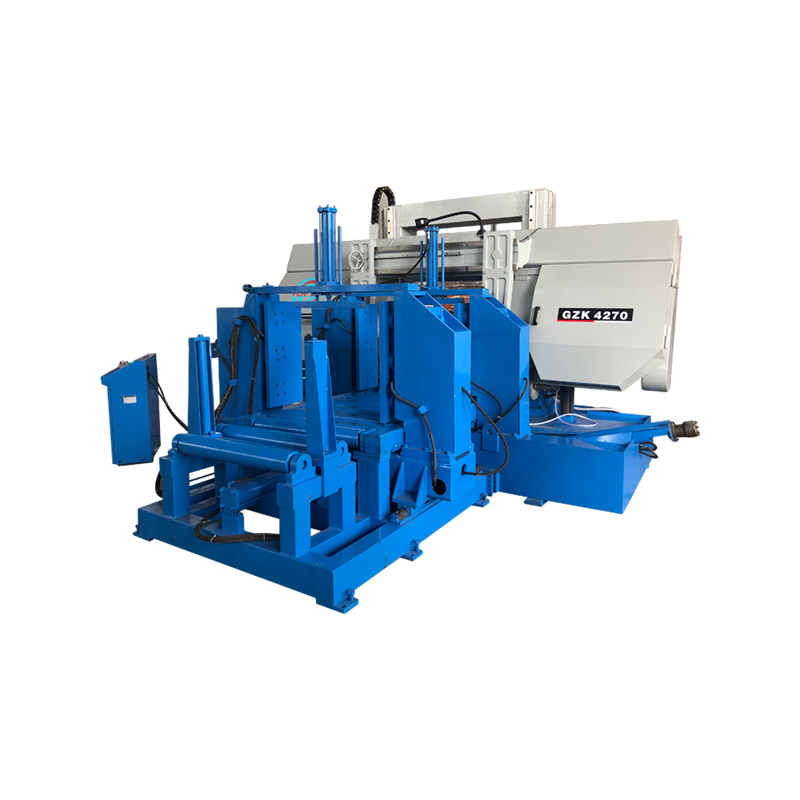

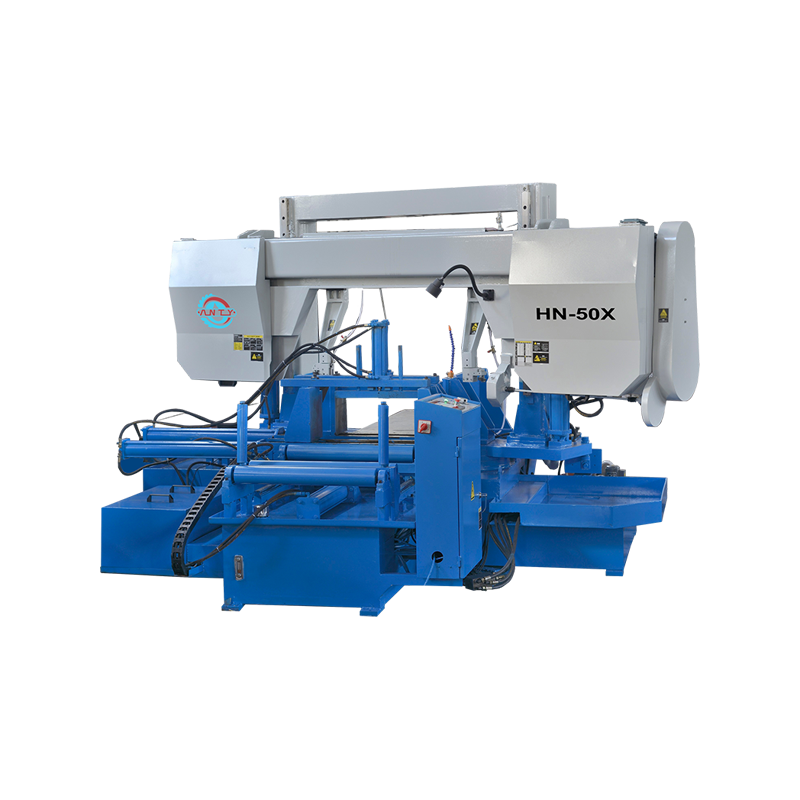

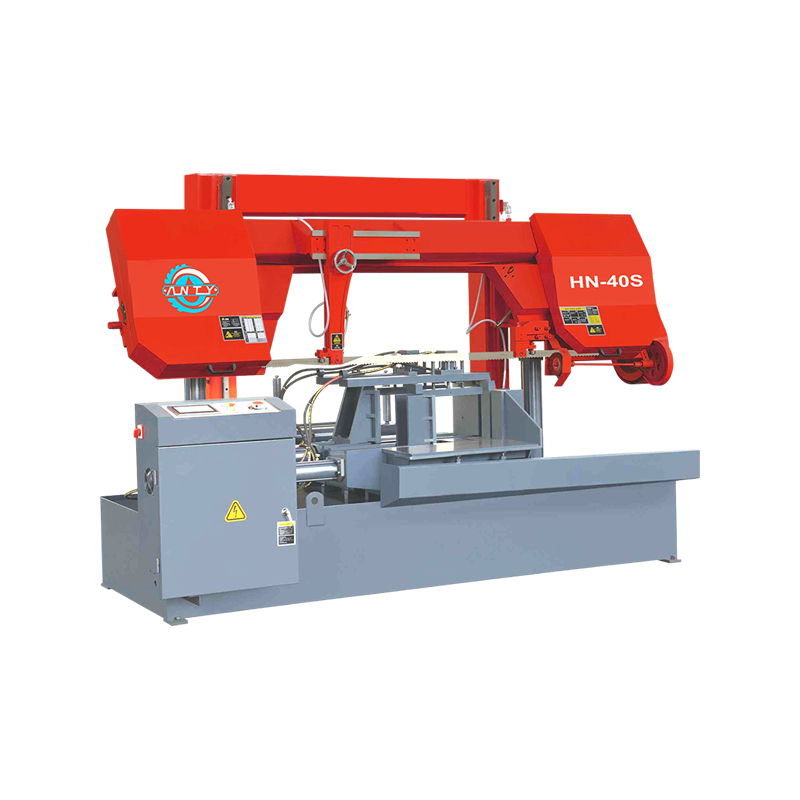

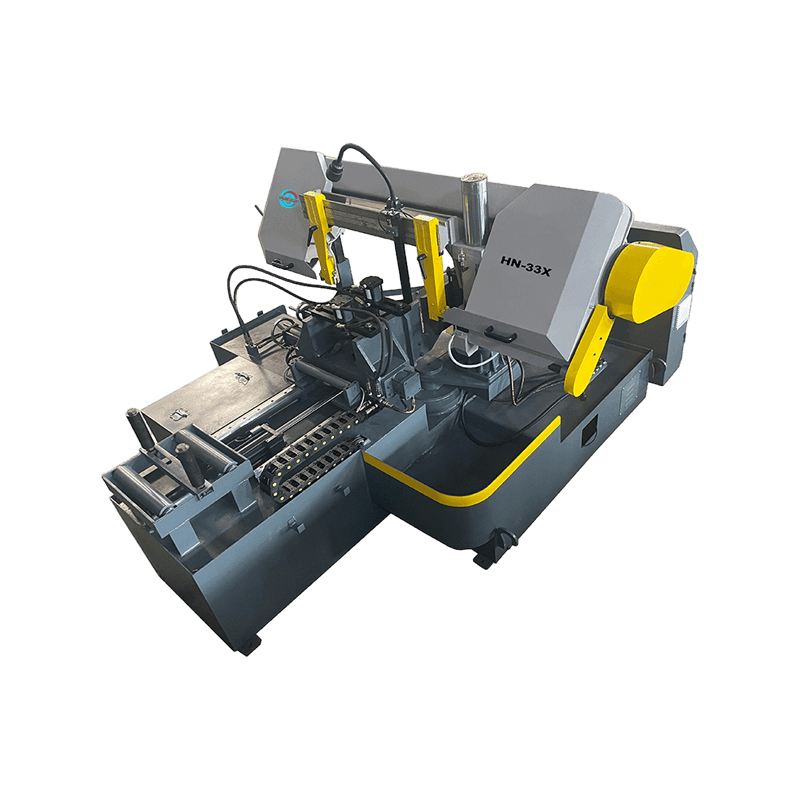

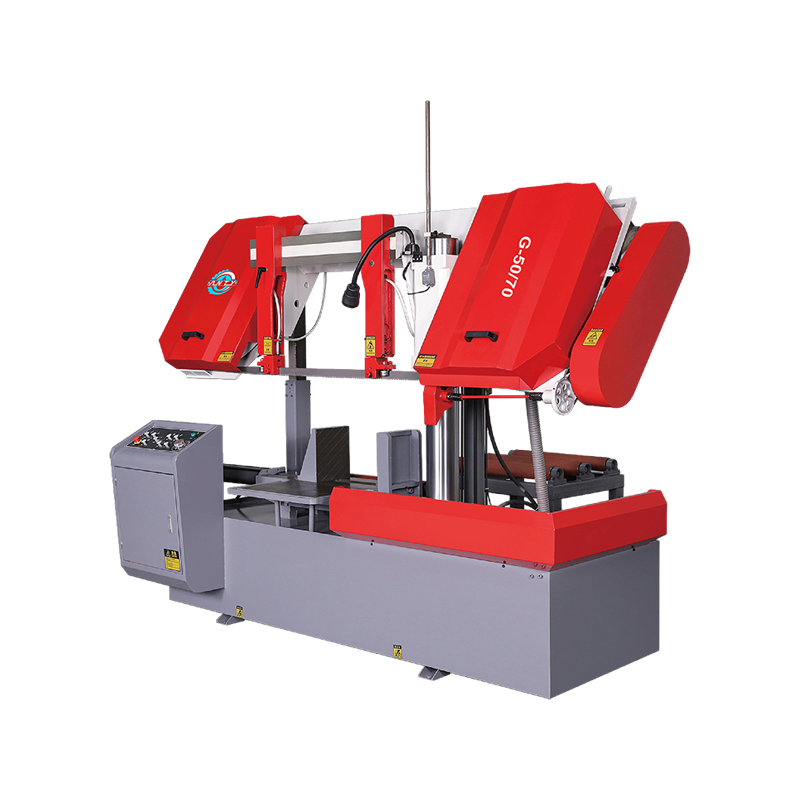

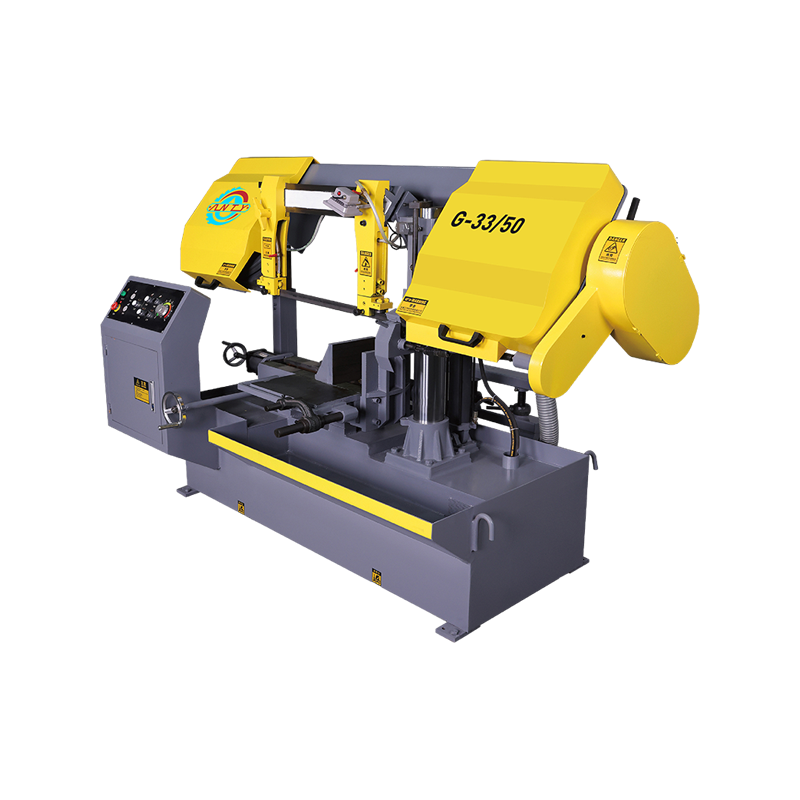

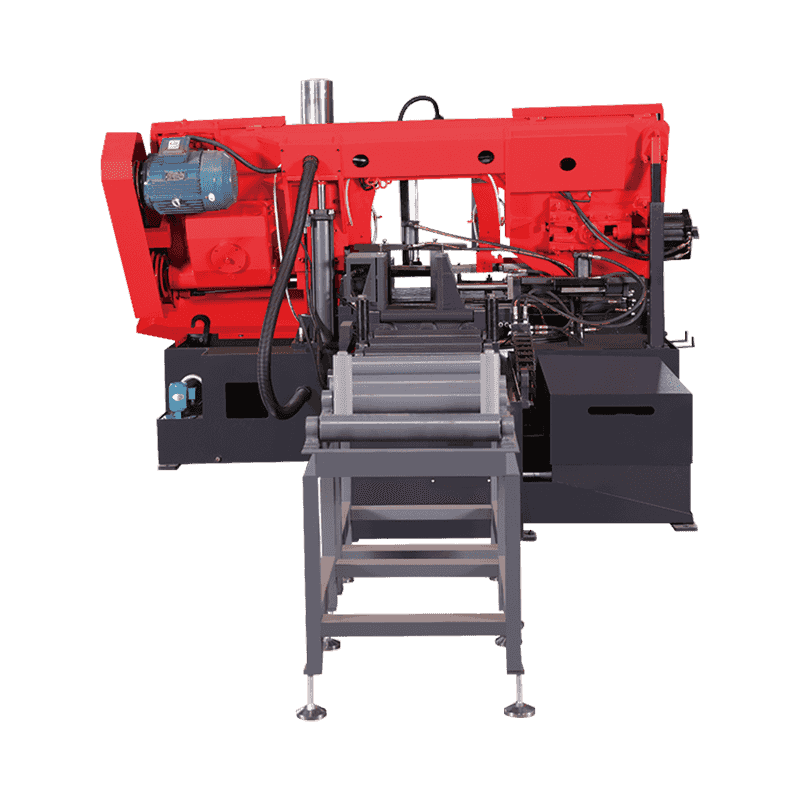

Professional Manufacturer Of Hydraulic Metal Cutting Band Saw Machines

Committed to becoming a well-known manufacturer of hydraulic metal cutting band saw machines.

READ MORE

READ MORE

READ MORE

READ MORE

Advanced technical strength and effective technical guarantee.

Flexible business philosophy and professional services.

Advanced manufacturing technology, strictly controlled product quality and good reputation.

For any questions and feedback from customers, we will reply patiently and meticulously.

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

Pay Attention To Our Latest News And Exhibitions.

For various metalworking applications, a Metal Cutting Band Sawing Machine or a Rotary Angle Horizontal Metal Band Sawing Machine provides adaptable solutions for cutting different types of metal materials. These machines are used across automotive, aerospace, electronics, and machinery manufacturing, where accuracy, material handling, and cutting flexibility are essential. Understanding where these machines perform effectively helps operators select suitable processes and improve workflow efficiency. Automotive Parts Fabrication Rotary angle horizontal metal band sawing machines are commonly used in automotive manufacturing to cut engine components, transmission housings, chassis frames, and other structural parts. The ability to adjust cutting angles allows precise shaping of complex components. Operators can set the saw wheel to match the part specifications, ensuring cuts are aligned with design requirements while maintaining a smooth surface on the workpiece. Proper clamping and consistent feeding support accurate results for medium and large-sized automotive components. Aerospace and High-Strength Material Applications Aerospace manufacturing often requires cutting high-strength, high-hardness metals such as titanium and aluminum alloys. Rotary angle horizontal sawing machines can handle these materials by adjusting cutting speed, feed rate, and saw blade selection according to material properties. Stable workpiece support and controlled blade tension help reduce vibration during cutting. Monitoring the machine during operation ensures that the material is processed without unexpected shifts, which is particularly important for precision components used in aerospace assemblies. Electronics and Small Precision Parts In the electronics industry, these machines are used to cut small, precise metal components such as casings, connectors, and brackets. The rotary angle function allows operators to cut at different angles as needed for specialized components, providing versatility for diverse electronic parts. Consistent supervision of the cutting process ensures that each piece meets dimensional requirements. Machinery and Structural Metal Cutting Machinery manufacturing requires handling large and heavy metal sections, including machine bases, bearing seats, and frames. The horizontal design and adjustable angle capability of these sawing machines allow operators to work with long or thick materials more efficiently. Proper fixture placement and supporting the workpiece along the cutting path help maintain stability, reduce blade stress, and produce a cleaner cut. Regular inspection of blades and machine alignment ensures reliable operation over extended production runs. Pipes, Flanges, and Industrial Components Rotary angle horizontal metal band sawing machines are also applied in energy and industrial sectors for cutting pipes, flanges, and structural metal components. Adjusting the saw angle and monitoring feed rate help achieve consistent cuts on cylindrical or irregularly shaped items. Cooling or lubrication is often used to maintain smooth cutting action, reduce friction, and maintain the condition of the saw blade. These practices support controlled and repeatable cutting performance across various metal materials. Maintenance and Operational Practices Consistent maintenance of saw blades, lubrication, and alignment supports stable operation and helps prevent interruptions. Operators should inspect the blade for wear, check mechanical guides, and clean debris after use. Maintaining a clear workspace and monitoring automated feeding and cutting functions contributes to both efficiency and safety. Recording operational observations, such as cutting speeds, material types, and surface quality, provides a reference for future adjustments and supports consistent results.

For various metalworking applications, a Metal Cutting Band Sawing Machine or a Rotary Angle Horizontal Metal Band Sawing Machine provides adaptable solutions for cutting different types of metal materials. These machines are used across automotive, aerospace, electronics, and machinery manufacturing, where accuracy, material handling, and cutting flexibility are essential. Understanding where these machines perform effectively helps operators select suitable processes and improve workflow efficiency. Automotive Parts Fabrication Rotary angle horizontal metal band sawing machines are commonly used in automotive manufacturing to cut engine components, transmission housings, chassis frames, and other structural parts. The ability to adjust cutting angles allows precise shaping of complex components. Operators can set the saw wheel to match the part specifications, ensuring cuts are aligned with design requirements while maintaining a smooth surface on the workpiece. Proper clamping and consistent feeding support accurate results for medium and large-sized automotive components. Aerospace and High-Strength Material Applications Aerospace manufacturing often requires cutting high-strength, high-hardness metals such as titanium and aluminum alloys. Rotary angle horizontal sawing machines can handle these materials by adjusting cutting speed, feed rate, and saw blade selection according to material properties. Stable workpiece support and controlled blade tension help reduce vibration during cutting. Monitoring the machine during operation ensures that the material is processed without unexpected shifts, which is particularly important for precision components used in aerospace assemblies. Electronics and Small Precision Parts In the electronics industry, these machines are used to cut small, precise metal components such as casings, connectors, and brackets. The rotary angle function allows operators to cut at different angles as needed for specialized components, providing versatility for diverse electronic parts. Consistent supervision of the cutting process ensures that each piece meets dimensional requirements. Machinery and Structural Metal Cutting Machinery manufacturing requires handling large and heavy metal sections, including machine bases, bearing seats, and frames. The horizontal design and adjustable angle capability of these sawing machines allow operators to work with long or thick materials more efficiently. Proper fixture placement and supporting the workpiece along the cutting path help maintain stability, reduce blade stress, and produce a cleaner cut. Regular inspection of blades and machine alignment ensures reliable operation over extended production runs. Pipes, Flanges, and Industrial Components Rotary angle horizontal metal band sawing machines are also applied in energy and industrial sectors for cutting pipes, flanges, and structural metal components. Adjusting the saw angle and monitoring feed rate help achieve consistent cuts on cylindrical or irregularly shaped items. Cooling or lubrication is often used to maintain smooth cutting action, reduce friction, and maintain the condition of the saw blade. These practices support controlled and repeatable cutting performance across various metal materials. Maintenance and Operational Practices Consistent maintenance of saw blades, lubrication, and alignment supports stable operation and helps prevent interruptions. Operators should inspect the blade for wear, check mechanical guides, and clean debris after use. Maintaining a clear workspace and monitoring automated feeding and cutting functions contributes to both efficiency and safety. Recording operational observations, such as cutting speeds, material types, and surface quality, provides a reference for future adjustments and supports consistent results.

READ MORE

READ MORE

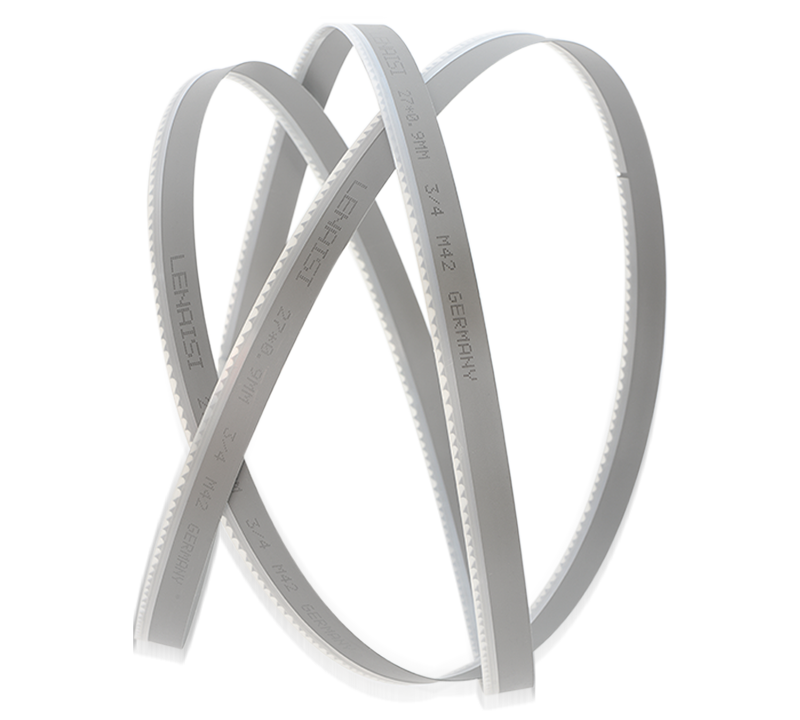

Handling different types of metal materials often results in varying efficiency when using a Metal Cutting Band Sawing Machine or a Rotary Angle Horizontal Metal Band Sawing Machine. Differences in hardness, thickness, and structural properties of metals can affect cutting speed, surface finish, and overall workflow. Understanding the factors that influence machine performance across materials helps operators adjust settings, plan production, and reduce unnecessary wear on equipment. Material Properties and Cutting Resistance Different metals offer varying levels of resistance to cutting. Softer metals such as aluminum or mild steel tend to cut more smoothly, while harder metals like stainless steel, titanium alloys, or high-strength steel require slower cutting speeds and more stable feed rates. The density, grain structure, and surface treatment of a material can also affect how the saw blade interacts with the metal. Recognizing these characteristics helps in selecting an appropriate saw wheel type and feed adjustment for each material. Saw Blade Type and Condition The efficiency of a metal cutting band sawing machine depends heavily on the saw blade itself. Blades with finer teeth are generally suitable for cutting thin or softer materials, while blades with larger teeth are used for thick or hard metals. Blade wear, dulling, or improper tension can reduce cutting efficiency regardless of material type. Regular inspection, timely replacement, and proper adjustment of the saw blade support more consistent cutting speed and reduce interruptions caused by uneven cutting or overheating. Cutting Speed and Feed Rate Adjustments Operators need to adjust both the cutting speed and feed rate according to the material being processed. Using a consistent feed rate without considering material hardness may result in slower cutting, increased friction, or rough edges. Slower speeds and steady feeding are often required for dense or tough metals, while lighter metals can be processed with faster rotation and movement. Monitoring the cutting process and adjusting these parameters helps maintain smooth operation and preserves the condition of the machine. Workpiece Support and Positioning Maintaining stability of the workpiece is critical for cutting efficiency. Larger or irregularly shaped metal pieces can shift or vibrate during cutting, affecting precision and speed. Clamps, fixtures, or additional supports are used to secure materials firmly in place. Correct positioning also helps distribute cutting forces evenly, which prevents uneven wear on the saw blade and reduces unnecessary stress on the machine frame. Cooling and Lubrication Many metals generate significant heat during cutting, which can impact efficiency and the surface quality of the cut. Applying appropriate cooling or lubrication during operation helps the saw blade move more smoothly through the material and reduces friction. While the amount and type of coolant depend on the metal being cut, consistent attention to this aspect contributes to stable cutting performance. Operator Awareness and Monitoring Even with automated feeding and cutting functions, operators play a key role in maintaining efficiency. Observing the machine during cutting allows for timely adjustments when material properties, workpiece alignment, or blade condition affect performance. Keeping a log of material types, cutting parameters, and results can guide future settings and support more predictable processing across different metals. Efficiency variations in metal cutting band sawing machines are influenced by a combination of material characteristics, saw blade selection, cutting parameters, workpiece stability, and operational monitoring. By understanding how each factor interacts with the machine, operators can adjust procedures to support consistent cutting performance and reduce unnecessary interruptions.

Handling different types of metal materials often results in varying efficiency when using a Metal Cutting Band Sawing Machine or a Rotary Angle Horizontal Metal Band Sawing Machine. Differences in hardness, thickness, and structural properties of metals can affect cutting speed, surface finish, and overall workflow. Understanding the factors that influence machine performance across materials helps operators adjust settings, plan production, and reduce unnecessary wear on equipment. Material Properties and Cutting Resistance Different metals offer varying levels of resistance to cutting. Softer metals such as aluminum or mild steel tend to cut more smoothly, while harder metals like stainless steel, titanium alloys, or high-strength steel require slower cutting speeds and more stable feed rates. The density, grain structure, and surface treatment of a material can also affect how the saw blade interacts with the metal. Recognizing these characteristics helps in selecting an appropriate saw wheel type and feed adjustment for each material. Saw Blade Type and Condition The efficiency of a metal cutting band sawing machine depends heavily on the saw blade itself. Blades with finer teeth are generally suitable for cutting thin or softer materials, while blades with larger teeth are used for thick or hard metals. Blade wear, dulling, or improper tension can reduce cutting efficiency regardless of material type. Regular inspection, timely replacement, and proper adjustment of the saw blade support more consistent cutting speed and reduce interruptions caused by uneven cutting or overheating. Cutting Speed and Feed Rate Adjustments Operators need to adjust both the cutting speed and feed rate according to the material being processed. Using a consistent feed rate without considering material hardness may result in slower cutting, increased friction, or rough edges. Slower speeds and steady feeding are often required for dense or tough metals, while lighter metals can be processed with faster rotation and movement. Monitoring the cutting process and adjusting these parameters helps maintain smooth operation and preserves the condition of the machine. Workpiece Support and Positioning Maintaining stability of the workpiece is critical for cutting efficiency. Larger or irregularly shaped metal pieces can shift or vibrate during cutting, affecting precision and speed. Clamps, fixtures, or additional supports are used to secure materials firmly in place. Correct positioning also helps distribute cutting forces evenly, which prevents uneven wear on the saw blade and reduces unnecessary stress on the machine frame. Cooling and Lubrication Many metals generate significant heat during cutting, which can impact efficiency and the surface quality of the cut. Applying appropriate cooling or lubrication during operation helps the saw blade move more smoothly through the material and reduces friction. While the amount and type of coolant depend on the metal being cut, consistent attention to this aspect contributes to stable cutting performance. Operator Awareness and Monitoring Even with automated feeding and cutting functions, operators play a key role in maintaining efficiency. Observing the machine during cutting allows for timely adjustments when material properties, workpiece alignment, or blade condition affect performance. Keeping a log of material types, cutting parameters, and results can guide future settings and support more predictable processing across different metals. Efficiency variations in metal cutting band sawing machines are influenced by a combination of material characteristics, saw blade selection, cutting parameters, workpiece stability, and operational monitoring. By understanding how each factor interacts with the machine, operators can adjust procedures to support consistent cutting performance and reduce unnecessary interruptions.

READ MORE

READ MORE

For industries handling various metal materials, a Metal Cutting Band Sawing Machine or a Rotary Angle Horizontal Metal Band Sawing Machine can play a significant role in enhancing cutting processes. These machines are designed to handle materials ranging from small precision parts to large metal sections, providing controlled cutting for applications in automotive, aerospace, machinery, and electronics sectors. Understanding how these machines can improve cutting involves examining setup, operational adjustments, material handling, and maintenance practices. Adapting Cutting Angles for Complex Parts Rotary angle horizontal metal band sawing machines allow the saw wheel angle to be adjusted according to the cutting requirements. This flexibility supports the processing of parts that require non-standard angles, such as engine components, frames, or structural supports. Properly setting the angle ensures that cuts are aligned with design specifications and reduces the likelihood of material waste. Operators should verify that the workpiece is securely clamped and that the saw blade aligns with the intended angle to maintain consistent cut quality. Controlling Speed and Feed for Material Types Different metal materials respond differently to cutting. Soft metals like aluminum require a different cutting speed compared with harder metals such as stainless steel or titanium alloys. Adjusting the cutting speed and feed rate according to the material helps maintain smooth cutting motion, prevents undue strain on the saw blade, and reduces surface irregularities. Observing the cutting process and making incremental adjustments can improve precision and reduce the risk of uneven edges. Enhancing Workpiece Stability Workpiece stability is a critical factor for clean cuts. Rotary angle horizontal metal band sawing machines often include fixtures or clamps that hold the material firmly during operation. Ensuring that these fixtures are properly positioned helps prevent vibration and shifting during cutting. For longer or heavier materials, additional supports along the cutting path can prevent sagging or misalignment. Stable positioning supports consistent cutting accuracy and can extend the life of the saw blade. Maintaining Equipment for Consistent Performance Regular maintenance contributes to reliable cutting performance. Inspecting saw blades for wear, teeth damage, or cracks allows operators to replace or adjust them before they affect cutting quality. Lubrication of moving parts, checking alignment, and cleaning debris from the cutting area ensures that the machine operates smoothly. Consistent maintenance prevents interruptions during production and helps maintain the desired surface finish. Organizing Workflow and Safety Measures A well-organized workspace allows operators to focus on cutting tasks without obstruction. Ensuring adequate space around the machine, proper lighting, and accessible control panels reduces the chance of errors or accidents. Operators should follow recommended safety measures, including protective equipment and monitoring automated feeding and cutting functions. Proper handling reduces the likelihood of material damage or personal injury, supporting a safer and more controlled cutting environment. Monitoring and Adjusting for Different Applications Rotary angle horizontal metal band sawing machines are used for a range of applications, from cutting automotive parts to preparing components for machinery assembly. Monitoring the machine’s performance during different tasks allows operators to make adjustments suited to each material or part type. Recording observations, such as blade wear patterns or cutting surface conditions, provides guidance for future adjustments and supports consistent results across multiple production cycles.

For industries handling various metal materials, a Metal Cutting Band Sawing Machine or a Rotary Angle Horizontal Metal Band Sawing Machine can play a significant role in enhancing cutting processes. These machines are designed to handle materials ranging from small precision parts to large metal sections, providing controlled cutting for applications in automotive, aerospace, machinery, and electronics sectors. Understanding how these machines can improve cutting involves examining setup, operational adjustments, material handling, and maintenance practices. Adapting Cutting Angles for Complex Parts Rotary angle horizontal metal band sawing machines allow the saw wheel angle to be adjusted according to the cutting requirements. This flexibility supports the processing of parts that require non-standard angles, such as engine components, frames, or structural supports. Properly setting the angle ensures that cuts are aligned with design specifications and reduces the likelihood of material waste. Operators should verify that the workpiece is securely clamped and that the saw blade aligns with the intended angle to maintain consistent cut quality. Controlling Speed and Feed for Material Types Different metal materials respond differently to cutting. Soft metals like aluminum require a different cutting speed compared with harder metals such as stainless steel or titanium alloys. Adjusting the cutting speed and feed rate according to the material helps maintain smooth cutting motion, prevents undue strain on the saw blade, and reduces surface irregularities. Observing the cutting process and making incremental adjustments can improve precision and reduce the risk of uneven edges. Enhancing Workpiece Stability Workpiece stability is a critical factor for clean cuts. Rotary angle horizontal metal band sawing machines often include fixtures or clamps that hold the material firmly during operation. Ensuring that these fixtures are properly positioned helps prevent vibration and shifting during cutting. For longer or heavier materials, additional supports along the cutting path can prevent sagging or misalignment. Stable positioning supports consistent cutting accuracy and can extend the life of the saw blade. Maintaining Equipment for Consistent Performance Regular maintenance contributes to reliable cutting performance. Inspecting saw blades for wear, teeth damage, or cracks allows operators to replace or adjust them before they affect cutting quality. Lubrication of moving parts, checking alignment, and cleaning debris from the cutting area ensures that the machine operates smoothly. Consistent maintenance prevents interruptions during production and helps maintain the desired surface finish. Organizing Workflow and Safety Measures A well-organized workspace allows operators to focus on cutting tasks without obstruction. Ensuring adequate space around the machine, proper lighting, and accessible control panels reduces the chance of errors or accidents. Operators should follow recommended safety measures, including protective equipment and monitoring automated feeding and cutting functions. Proper handling reduces the likelihood of material damage or personal injury, supporting a safer and more controlled cutting environment. Monitoring and Adjusting for Different Applications Rotary angle horizontal metal band sawing machines are used for a range of applications, from cutting automotive parts to preparing components for machinery assembly. Monitoring the machine’s performance during different tasks allows operators to make adjustments suited to each material or part type. Recording observations, such as blade wear patterns or cutting surface conditions, provides guidance for future adjustments and supports consistent results across multiple production cycles.

READ MORE

READ MORE

Operating a Metal Cutting Band Sawing Machine or a Rotary Angle Horizontal Metal Band Sawing Machine requires careful attention to safety and procedural standards. These machines, widely used in industries such as automotive, aerospace, electronics, and machinery manufacturing, handle metal materials of varying hardness and dimensions. Ensuring smooth operation is not only a matter of productivity but also of workplace safety. Understanding the proper precautions, handling techniques, and maintenance practices can prevent accidents, improve machine lifespan, and support consistent cutting quality. Understanding Machine Setup and Operation Before starting the machine, it is important to familiarize oneself with its structure and controls. A rotary angle horizontal metal band sawing machine typically allows angle adjustments and automatic feeding functions. Operators should verify that the saw wheel type and cutting range are appropriate for the material and part size. Proper setup includes securing the workpiece firmly, aligning the saw wheel at the desired angle, and checking that all guards and safety covers are in place. Misalignment or inadequate clamping can cause vibration, uneven cuts, or damage to the saw blade. New users or those transitioning between manual and automatic sawing machines should review operational manuals carefully. Understanding the sequence for starting, feeding, cutting, and stopping the machine helps prevent improper operation. Training sessions can also cover emergency stop procedures, allowing operators to react promptly if unexpected situations arise. Maintaining Saw Blade and Components Saw blades on metal cutting band sawing machines undergo significant stress during operation. Regular inspection is necessary to check for wear, cracks, or teeth damage. Using a worn blade can cause inaccurate cuts, increased friction, or potential breakage. In addition to the blade, mechanical components such as the saw wheel, guides, and bearings should be checked for proper lubrication and alignment. Proper maintenance ensures that the rotary mechanism runs smoothly and reduces unnecessary strain on the machine. Cleaning the machine after each use is also important. Metal debris, dust, and coolant residues can accumulate, affecting the cutting surface and moving parts. Removing these materials prevents unexpected resistance during cutting and lowers the risk of overheating. Safe Handling During Cutting Operations While the machine is operating, operators should maintain a safe distance and avoid reaching near moving components. Protective barriers, gloves, and safety goggles are recommended to reduce the risk of injury from flying debris or accidental contact with the saw. For automatic rotary angle sawing machines, monitoring the feeding and receiving functions is crucial. Even if the machine operates automatically, supervision ensures that the workpiece moves smoothly and that jams or misfeeds are addressed promptly. It is also helpful to use consistent cutting speed and feed rate appropriate for the material. Adjusting the speed too quickly or forcing the feed can stress the blade, increase vibration, and create uneven cuts. Observing the machine during the cutting process allows operators to notice any unusual sounds or motions that may indicate mechanical issues. Electrical Safety and Workspace Organization Rotary angle horizontal metal band sawing machines rely on electrical components for motor operation, automatic feeding, and angle adjustment. Ensuring that power cables are in good condition and that the machine is properly grounded reduces the risk of electrical accidents. Disconnecting power during maintenance or blade replacement is essential to avoid accidental startup. Organizing the workspace around the sawing machine supports both safety and efficiency. Keeping tools, materials, and debris away from moving parts prevents accidental trips or interference with the machine. Adequate lighting and clear floor space also help operators maintain focus and precision during cutting tasks. Regular Monitoring and Record Keeping Keeping records of machine usage, maintenance, and inspections provides a practical reference for identifying recurring issues. Scheduled checks on blade condition, alignment, lubrication, and safety features allow operators to address minor problems before they affect operation. Tracking operating hours and performance can also guide decisions about component replacement or adjustments, supporting continuous, smooth operation.

Operating a Metal Cutting Band Sawing Machine or a Rotary Angle Horizontal Metal Band Sawing Machine requires careful attention to safety and procedural standards. These machines, widely used in industries such as automotive, aerospace, electronics, and machinery manufacturing, handle metal materials of varying hardness and dimensions. Ensuring smooth operation is not only a matter of productivity but also of workplace safety. Understanding the proper precautions, handling techniques, and maintenance practices can prevent accidents, improve machine lifespan, and support consistent cutting quality. Understanding Machine Setup and Operation Before starting the machine, it is important to familiarize oneself with its structure and controls. A rotary angle horizontal metal band sawing machine typically allows angle adjustments and automatic feeding functions. Operators should verify that the saw wheel type and cutting range are appropriate for the material and part size. Proper setup includes securing the workpiece firmly, aligning the saw wheel at the desired angle, and checking that all guards and safety covers are in place. Misalignment or inadequate clamping can cause vibration, uneven cuts, or damage to the saw blade. New users or those transitioning between manual and automatic sawing machines should review operational manuals carefully. Understanding the sequence for starting, feeding, cutting, and stopping the machine helps prevent improper operation. Training sessions can also cover emergency stop procedures, allowing operators to react promptly if unexpected situations arise. Maintaining Saw Blade and Components Saw blades on metal cutting band sawing machines undergo significant stress during operation. Regular inspection is necessary to check for wear, cracks, or teeth damage. Using a worn blade can cause inaccurate cuts, increased friction, or potential breakage. In addition to the blade, mechanical components such as the saw wheel, guides, and bearings should be checked for proper lubrication and alignment. Proper maintenance ensures that the rotary mechanism runs smoothly and reduces unnecessary strain on the machine. Cleaning the machine after each use is also important. Metal debris, dust, and coolant residues can accumulate, affecting the cutting surface and moving parts. Removing these materials prevents unexpected resistance during cutting and lowers the risk of overheating. Safe Handling During Cutting Operations While the machine is operating, operators should maintain a safe distance and avoid reaching near moving components. Protective barriers, gloves, and safety goggles are recommended to reduce the risk of injury from flying debris or accidental contact with the saw. For automatic rotary angle sawing machines, monitoring the feeding and receiving functions is crucial. Even if the machine operates automatically, supervision ensures that the workpiece moves smoothly and that jams or misfeeds are addressed promptly. It is also helpful to use consistent cutting speed and feed rate appropriate for the material. Adjusting the speed too quickly or forcing the feed can stress the blade, increase vibration, and create uneven cuts. Observing the machine during the cutting process allows operators to notice any unusual sounds or motions that may indicate mechanical issues. Electrical Safety and Workspace Organization Rotary angle horizontal metal band sawing machines rely on electrical components for motor operation, automatic feeding, and angle adjustment. Ensuring that power cables are in good condition and that the machine is properly grounded reduces the risk of electrical accidents. Disconnecting power during maintenance or blade replacement is essential to avoid accidental startup. Organizing the workspace around the sawing machine supports both safety and efficiency. Keeping tools, materials, and debris away from moving parts prevents accidental trips or interference with the machine. Adequate lighting and clear floor space also help operators maintain focus and precision during cutting tasks. Regular Monitoring and Record Keeping Keeping records of machine usage, maintenance, and inspections provides a practical reference for identifying recurring issues. Scheduled checks on blade condition, alignment, lubrication, and safety features allow operators to address minor problems before they affect operation. Tracking operating hours and performance can also guide decisions about component replacement or adjustments, supporting continuous, smooth operation.

READ MORE

READ MORE

We are pleased to announce that our machine has officially shipped today and is now on its journey to the customer. After weeks of meticulous preparation, quality checks, and final adjustments, it is rewarding to see the product ready for delivery. Each unit we produce undergoes a rigorous inspection process to ensure that it meets the high standards our clients expect. Lishui Aiteli Machine Equipment Co., Ltd. is a company specializing in the production of metal cutting band saws, high-speed circular band saws, band saw blades, and other precision tools. With a long history in the Chinese market, our machines are recognized for their durability, cost-effectiveness, and reliable performance. As a well-known heavy machinery manufacturer in southern Zhejiang, we have consistently focused on product quality and building a strong reputation. Our factory has been honored with titles such as "Enterprise with Trustworthy Product Quality" and "Contract-abiding And Credit-worthy Enterprise" for many years.The customer has been eagerly anticipating the arrival of this machine, and we look forward to receiving their feedback. Each order entrusted to us is handled with care and efficiency, reflecting our commitment to high-quality manufacturing and responsive service. We are confident that this shipment will contribute positively to the customer’s operations and further demonstrate our dedication to excellence in machinery production.

We are pleased to announce that our machine has officially shipped today and is now on its journey to the customer. After weeks of meticulous preparation, quality checks, and final adjustments, it is rewarding to see the product ready for delivery. Each unit we produce undergoes a rigorous inspection process to ensure that it meets the high standards our clients expect. Lishui Aiteli Machine Equipment Co., Ltd. is a company specializing in the production of metal cutting band saws, high-speed circular band saws, band saw blades, and other precision tools. With a long history in the Chinese market, our machines are recognized for their durability, cost-effectiveness, and reliable performance. As a well-known heavy machinery manufacturer in southern Zhejiang, we have consistently focused on product quality and building a strong reputation. Our factory has been honored with titles such as "Enterprise with Trustworthy Product Quality" and "Contract-abiding And Credit-worthy Enterprise" for many years.The customer has been eagerly anticipating the arrival of this machine, and we look forward to receiving their feedback. Each order entrusted to us is handled with care and efficiency, reflecting our commitment to high-quality manufacturing and responsive service. We are confident that this shipment will contribute positively to the customer’s operations and further demonstrate our dedication to excellence in machinery production.

READ MORE

READ MORE

Unexpected variations in cutting performance are common when operators switch between a CNC full automatic High speed circular sawing machine and a Metal cutting Band sawing machine, especially when dealing with metals of different hardness levels. Many users notice that blade wear, surface finish, and cutting stability change noticeably with different feed rates. Understanding why feed rate affects blade behavior helps users set up stable machining conditions and reduce unnecessary downtime during routine production. How Feed Rate Influences Blade Contact and Cutting Pressure Feed rate directly determines how aggressively the blade engages with the workpiece. When the feed rate is higher than what the blade tooth geometry can handle, each tooth removes a larger portion of material. This increases cutting pressure, causing the blade to run under a heavier load than it is designed for. With too much pressure, tooth edges may chip, especially when cutting solid bars or high-strength alloys.On the other hand, overly low feed rates may seem safe, but they allow the blade to rub rather than cut. Rubbing generates heat at the tooth tips and can cause rapid dulling. Both high and low feed settings introduce unnecessary stress on the blade. Maintaining a moderate and consistent feed rate offers better tooth engagement, limiting heat buildup and helping the blade stay sharp for a longer period. Why Band Saw Blades React More Strongly Than Circular Saw Blades Circular saws used in CNC full automatic high speed systems usually have a rigid blade body, short cutting engagement time, and fixed chip load per tooth. This stability helps distribute forces more evenly.Band saw blades, in contrast, have a flexible body and a much longer cutting arc. During operation, the blade remains in contact with the material for a longer period per revolution, so any feed rate variation directly affects a larger section of the blade. Even small changes in feed rate can shift cutting forces along the blade length, resulting in deviations, vibration, or tooth marking.Because of this flexibility, band saw blades depend heavily on consistent feed pressure. Even when cutting the same alloy, the blade’s performance may differ if the workpiece cross-section varies. Understanding this sensitivity helps operators tune parameters more carefully for band sawing operations. Heat Generation and Its Connection to Feed Variation Heat buildup during metal cutting is unavoidable, but feed rate determines how this heat is distributed. When the feed rate is steady and appropriate for the material, chips carry away a portion of the heat. However:Too low a feed rate creates fine, powder-like chips that retain heat near the blade.Too high a feed rate produces thick chips that increase friction and temperature at the cutting edge.Heat affects band saw blades more significantly because the cutting teeth are smaller and thinner compared to circular saw blades. Elevated temperature can soften the tooth surface or cause the backing material to lose stiffness. These changes make the blade more prone to drifting during the cut. Operators often interpret this as poor blade quality, but the root cause often lies in feed settings rather than the blade itself. Influence of Material Structure and Cross-Section on Feed Sensitivity Different metals react differently under the same feed rate. For example, materials with uneven grain structure, such as forged components, can cause inconsistent cutting resistance. In such cases, the blade experiences alternating hard and soft sections, which amplifies the effects of feed rate changes.Large cross-sections also require careful feed control. A thick bar causes the blade to remain under load for a longer period per stroke, so even a slight increase in feed rate raises cutting resistance. Many operators notice blade chatter when transitioning from cutting hollow tubes to solid bars. This occurs because the feed rate that worked well for thin-walled materials becomes unsuitable when the contact area increases. Why Stable Feed Rate Protects Blade Geometry Blade teeth are engineered with specific rake angles and spacing to remove chips smoothly. When feed rate is unstable—either due to machine vibration, uneven workpiece clamping, or inconsistent hydraulic feed control—the tooth geometry cannot maintain steady chip formation. Irregular cutting removes metal in a fragmented pattern, increasing tooth friction and pushing the blade off its intended line.Maintaining a balanced feed rate allows each tooth to cut predictably, letting chips curl and exit properly. This consistency reduces the chance of tooth deformation and contributes to a more uniform cutting surface. It also helps prevent early blade replacement, which many workshops struggle with during continuous production. How Operators Can Adjust Feed Rate to Reduce Problems Users can take straightforward steps to manage feed-related sensitivity:Observe chip shape: curled chips indicate that feed settings are within a practical range.Listen to cutting sound: smooth and rhythmic cutting sounds suggest stable cutting pressure.Check for blade deflection: if the blade wanders, the feed rate may need adjustment.Evaluate material hardness beforehand: tougher alloys often require lower feed pressure.

Unexpected variations in cutting performance are common when operators switch between a CNC full automatic High speed circular sawing machine and a Metal cutting Band sawing machine, especially when dealing with metals of different hardness levels. Many users notice that blade wear, surface finish, and cutting stability change noticeably with different feed rates. Understanding why feed rate affects blade behavior helps users set up stable machining conditions and reduce unnecessary downtime during routine production. How Feed Rate Influences Blade Contact and Cutting Pressure Feed rate directly determines how aggressively the blade engages with the workpiece. When the feed rate is higher than what the blade tooth geometry can handle, each tooth removes a larger portion of material. This increases cutting pressure, causing the blade to run under a heavier load than it is designed for. With too much pressure, tooth edges may chip, especially when cutting solid bars or high-strength alloys.On the other hand, overly low feed rates may seem safe, but they allow the blade to rub rather than cut. Rubbing generates heat at the tooth tips and can cause rapid dulling. Both high and low feed settings introduce unnecessary stress on the blade. Maintaining a moderate and consistent feed rate offers better tooth engagement, limiting heat buildup and helping the blade stay sharp for a longer period. Why Band Saw Blades React More Strongly Than Circular Saw Blades Circular saws used in CNC full automatic high speed systems usually have a rigid blade body, short cutting engagement time, and fixed chip load per tooth. This stability helps distribute forces more evenly.Band saw blades, in contrast, have a flexible body and a much longer cutting arc. During operation, the blade remains in contact with the material for a longer period per revolution, so any feed rate variation directly affects a larger section of the blade. Even small changes in feed rate can shift cutting forces along the blade length, resulting in deviations, vibration, or tooth marking.Because of this flexibility, band saw blades depend heavily on consistent feed pressure. Even when cutting the same alloy, the blade’s performance may differ if the workpiece cross-section varies. Understanding this sensitivity helps operators tune parameters more carefully for band sawing operations. Heat Generation and Its Connection to Feed Variation Heat buildup during metal cutting is unavoidable, but feed rate determines how this heat is distributed. When the feed rate is steady and appropriate for the material, chips carry away a portion of the heat. However:Too low a feed rate creates fine, powder-like chips that retain heat near the blade.Too high a feed rate produces thick chips that increase friction and temperature at the cutting edge.Heat affects band saw blades more significantly because the cutting teeth are smaller and thinner compared to circular saw blades. Elevated temperature can soften the tooth surface or cause the backing material to lose stiffness. These changes make the blade more prone to drifting during the cut. Operators often interpret this as poor blade quality, but the root cause often lies in feed settings rather than the blade itself. Influence of Material Structure and Cross-Section on Feed Sensitivity Different metals react differently under the same feed rate. For example, materials with uneven grain structure, such as forged components, can cause inconsistent cutting resistance. In such cases, the blade experiences alternating hard and soft sections, which amplifies the effects of feed rate changes.Large cross-sections also require careful feed control. A thick bar causes the blade to remain under load for a longer period per stroke, so even a slight increase in feed rate raises cutting resistance. Many operators notice blade chatter when transitioning from cutting hollow tubes to solid bars. This occurs because the feed rate that worked well for thin-walled materials becomes unsuitable when the contact area increases. Why Stable Feed Rate Protects Blade Geometry Blade teeth are engineered with specific rake angles and spacing to remove chips smoothly. When feed rate is unstable—either due to machine vibration, uneven workpiece clamping, or inconsistent hydraulic feed control—the tooth geometry cannot maintain steady chip formation. Irregular cutting removes metal in a fragmented pattern, increasing tooth friction and pushing the blade off its intended line.Maintaining a balanced feed rate allows each tooth to cut predictably, letting chips curl and exit properly. This consistency reduces the chance of tooth deformation and contributes to a more uniform cutting surface. It also helps prevent early blade replacement, which many workshops struggle with during continuous production. How Operators Can Adjust Feed Rate to Reduce Problems Users can take straightforward steps to manage feed-related sensitivity:Observe chip shape: curled chips indicate that feed settings are within a practical range.Listen to cutting sound: smooth and rhythmic cutting sounds suggest stable cutting pressure.Check for blade deflection: if the blade wanders, the feed rate may need adjustment.Evaluate material hardness beforehand: tougher alloys often require lower feed pressure.

READ MORE

READ MORE

Across many fabrication workshops, equipment such as a CNC full automatic High speed circular sawing machine and a Metal cutting Band sawing machine are often used together to meet different cutting tasks. While circular saws handle rapid, high-volume jobs, workshops frequently depend on band sawing machines to manage varied profiles and thicker stock. Operators often observe that fabrication consistency can shift when workloads change, but many of these fluctuations trace back to specific areas where a band sawing machine can support steadier results. Understanding these points helps technicians maintain predictable output during daily operations. Consistent Feed Control Supports Steady Cutting Results A key influence on fabrication consistency lies in how smoothly the material feeds into the blade. Band sawing machines equipped with adjustable feed systems help keep cutting pressure more uniform, especially when working with solid bars, tubes, or irregular shapes. When feed control is set correctly, the blade moves through material without sudden resistance changes, which helps maintain more predictable cut surfaces.Technicians often notice that inconsistency appears when the feed rate is either too fast or too slow. A rate that is too fast may cause the blade to deflect, while a rate that is too slow can create friction and dull the blade earlier than expected. Making moderate adjustments based on material hardness and cross-section helps keep the cutting motion more stable. Periodic checks of hydraulic feed cylinders or mechanical feed components also support smoother operations. Cutting Accuracy Improves When the Blade Is Selected Properly Blade selection directly influences how consistent each workpiece turns out. Variations in tooth pitch, blade width, and material composition can affect how the machine handles different workloads. Using the same blade type for both thick and thin sections may produce inconsistent surfaces or length deviations.Workshops that frequently switch between profiles can benefit from a blade selection routine. This routine evaluates tooth pitch based on chip load, wall thickness, and material hardness. When the blade matches the application, the machine is less likely to experience excessive vibration, blade wandering, or heat buildup—all common factors affecting fabrication consistency. Recording preferred blade setups for repeated jobs also helps operators maintain predictable results. Stable Clamping and Workpiece Support Reduce Variation Another area where the band sawing machine contributes to consistency is in clamping and support. If a workpiece shifts during cutting, even slightly, the resulting cut lengths may differ. Stronger materials such as stainless steel or alloy steel amplify this effect because the blade encounters varying resistance.Ensuring the vise closes uniformly and holds the material securely helps avoid lateral movement. For longer workpieces, using auxiliary roller supports or adjustable stands can prevent sagging, especially during heavy-duty cuts. These small adjustments help ensure the machine encounters the same cutting conditions throughout the stroke, reducing variation in cut angle and length. Blade Guides and Alignment Play a Major Role in Predictable Dimensions Blade guides hold the blade in correct orientation as it moves through the workpiece. When guides are worn or misaligned, the blade may shift slightly, causing angled cuts or inconsistent surfaces. Routine inspection of guide arms, bearings, and carbide inserts helps keep the blade tracking accurately.Operators also benefit from checking vertical alignment between the blade and the vise. When the alignment is correct, the resulting cuts show better parallelism and fewer deviations across batches. Even small misalignments can accumulate during high-volume work, so periodic checks contribute to more stable and predictable results. Coolant Flow Helps Maintain Uniform Cutting Conditions A steady coolant flow helps control blade temperature and improve chip evacuation. When the blade overheats, it may expand slightly or lose sharpness more quickly, which in turn affects surface uniformity. If coolant passages are partially blocked, certain areas of the cut may cool differently, contributing to dimensional variation.Regular inspection of coolant levels, filters, and nozzle direction helps maintain even distribution. Technicians often adjust the coolant angle to ensure it reaches both sides of the blade during the cut. Consistent lubrication and cooling reduce friction-related changes that might otherwise affect fabrication consistency over longer production runs. Drive System Stability Enhances Cutting Repeatability The drive mechanism supports blade speed control, which has a direct influence on cutting results. When belts or pulleys wear, blade speed may fluctuate slightly. These fluctuations can be subtle, but over a long cut they may cause differences in chip formation, surface finish, or cutting angle.

Across many fabrication workshops, equipment such as a CNC full automatic High speed circular sawing machine and a Metal cutting Band sawing machine are often used together to meet different cutting tasks. While circular saws handle rapid, high-volume jobs, workshops frequently depend on band sawing machines to manage varied profiles and thicker stock. Operators often observe that fabrication consistency can shift when workloads change, but many of these fluctuations trace back to specific areas where a band sawing machine can support steadier results. Understanding these points helps technicians maintain predictable output during daily operations. Consistent Feed Control Supports Steady Cutting Results A key influence on fabrication consistency lies in how smoothly the material feeds into the blade. Band sawing machines equipped with adjustable feed systems help keep cutting pressure more uniform, especially when working with solid bars, tubes, or irregular shapes. When feed control is set correctly, the blade moves through material without sudden resistance changes, which helps maintain more predictable cut surfaces.Technicians often notice that inconsistency appears when the feed rate is either too fast or too slow. A rate that is too fast may cause the blade to deflect, while a rate that is too slow can create friction and dull the blade earlier than expected. Making moderate adjustments based on material hardness and cross-section helps keep the cutting motion more stable. Periodic checks of hydraulic feed cylinders or mechanical feed components also support smoother operations. Cutting Accuracy Improves When the Blade Is Selected Properly Blade selection directly influences how consistent each workpiece turns out. Variations in tooth pitch, blade width, and material composition can affect how the machine handles different workloads. Using the same blade type for both thick and thin sections may produce inconsistent surfaces or length deviations.Workshops that frequently switch between profiles can benefit from a blade selection routine. This routine evaluates tooth pitch based on chip load, wall thickness, and material hardness. When the blade matches the application, the machine is less likely to experience excessive vibration, blade wandering, or heat buildup—all common factors affecting fabrication consistency. Recording preferred blade setups for repeated jobs also helps operators maintain predictable results. Stable Clamping and Workpiece Support Reduce Variation Another area where the band sawing machine contributes to consistency is in clamping and support. If a workpiece shifts during cutting, even slightly, the resulting cut lengths may differ. Stronger materials such as stainless steel or alloy steel amplify this effect because the blade encounters varying resistance.Ensuring the vise closes uniformly and holds the material securely helps avoid lateral movement. For longer workpieces, using auxiliary roller supports or adjustable stands can prevent sagging, especially during heavy-duty cuts. These small adjustments help ensure the machine encounters the same cutting conditions throughout the stroke, reducing variation in cut angle and length. Blade Guides and Alignment Play a Major Role in Predictable Dimensions Blade guides hold the blade in correct orientation as it moves through the workpiece. When guides are worn or misaligned, the blade may shift slightly, causing angled cuts or inconsistent surfaces. Routine inspection of guide arms, bearings, and carbide inserts helps keep the blade tracking accurately.Operators also benefit from checking vertical alignment between the blade and the vise. When the alignment is correct, the resulting cuts show better parallelism and fewer deviations across batches. Even small misalignments can accumulate during high-volume work, so periodic checks contribute to more stable and predictable results. Coolant Flow Helps Maintain Uniform Cutting Conditions A steady coolant flow helps control blade temperature and improve chip evacuation. When the blade overheats, it may expand slightly or lose sharpness more quickly, which in turn affects surface uniformity. If coolant passages are partially blocked, certain areas of the cut may cool differently, contributing to dimensional variation.Regular inspection of coolant levels, filters, and nozzle direction helps maintain even distribution. Technicians often adjust the coolant angle to ensure it reaches both sides of the blade during the cut. Consistent lubrication and cooling reduce friction-related changes that might otherwise affect fabrication consistency over longer production runs. Drive System Stability Enhances Cutting Repeatability The drive mechanism supports blade speed control, which has a direct influence on cutting results. When belts or pulleys wear, blade speed may fluctuate slightly. These fluctuations can be subtle, but over a long cut they may cause differences in chip formation, surface finish, or cutting angle.

READ MORE

READ MORE

Workshops that operate both a CNC full automatic High speed circular sawing machine and a metal cutting band sawing machine often notice that stability in long-term band saw operation depends heavily on maintenance habits rather than equipment age alone. Many technicians focus only on blade replacement, yet a band sawing machine requires broader and more consistent care to maintain steady performance. Understanding these maintenance areas helps users prevent unexpected issues and keep the machine running smoothly during daily cutting tasks. Blade Condition Directly Affects Cutting Stability A worn, chipped, or improperly tensioned blade can cause vibration, uneven cutting surfaces, or deviations in length. Technicians should check the blade teeth regularly, especially when the machine handles harder materials.Correct blade tension helps keep the blade on track and reduces sideways movement. Some operators adjust tension only when noticing noise or surface inconsistencies, but checking tension before each shift provides a clearer baseline. If the workshop uses different blade widths for different tasks, confirming that each blade matches the machine’s tension range helps avoid unnecessary strain on the wheel system. Lubrication Helps Maintain Smooth Movement Lubrication is essential for the saw blade guide system, moving components, and bearings. Without regular lubrication, friction increases, which can create unstable cutting and unnecessary machine wear. Applying appropriate lubricant at recommended intervals helps keep the blade moving consistently through the guide arms.Coolant is another area often overlooked. A steady coolant flow keeps the blade temperature under control and supports more uniform cutting. When coolant passages become partially blocked, the blade may heat unevenly, affecting straightness. Operators should check coolant levels, filter screens, and nozzle direction to ensure a smooth, uninterrupted flow. Regular Alignment Checks Support Accurate Cutting Paths Misalignment can develop slowly as the machine experiences daily vibration and heavy workloads. When the band wheels, guide arms, or worktable drift out of alignment, the blade may wander during cutting. This does not always show immediate symptoms, but over time it affects cut accuracy and results in more material waste.Periodic checks of wheel alignment, guide arm parallelism, and vise positioning help technicians identify early signs of drift. Correcting small alignment deviations early prevents larger performance issues. For workshops using both circular sawing machines and band saws, maintaining alignment ensures that both machines produce consistent workpiece lengths, allowing them to complement each other without introducing dimensional differences. Cleaning Routines Reduce Build-Up That Affects Stability Metal chips and dust gradually accumulate around the blade path, drive wheels, and coolant system. Over time, these small particles can interfere with guide movement or cause unnecessary friction. A simple cleaning routine at the end of each shift can help prevent build-up in the machine’s moving areas.Removing chips from the blade gullets also matters. When gullets fill with debris, the blade may not clear chips efficiently, which can cause rough cutting or chatter. A clean machine is not only easier to inspect but also maintains more predictable cutting behavior. Checking the Drive System Helps Maintain Steady Power Transmission The drive belt, motor, and transmission components influence how smoothly power is delivered to the blade. If a belt starts slipping or develops cracks, the blade speed may fluctuate. These small fluctuations can affect cut quality, especially during long work cycles.Routine inspections of belt tension, motor temperature, and pulleys help technicians identify developing issues early. Replacing worn belts or tightening loose connections supports a more consistent cutting motion and reduces the chance of sudden performance drops during production. Hydraulic System Maintenance Supports Stable Clamping For band saws equipped with hydraulic tensioning or clamping systems, hydraulic health is essential. Low fluid levels, aging fluid, or worn seals can reduce clamping force. When the workpiece is not held firmly, vibration increases and the blade may drift during cutting.Technicians should monitor fluid condition and ensure that hoses and seals remain intact. Stable clamping is especially important when cutting heavy or solid stock, where any movement affects both accuracy and safety. Guide Arm and Vise Adjustments Influence Blade Tracking Guide arms keep the blade stable as it enters and exits the workpiece. If the guides sit too far from the material, the blade may be allowed to flex. If set too close, friction increases. Finding the correct spacing is essential for smooth cutting.The vise should also close uniformly and apply even pressure. Uneven clamping forces can tilt the workpiece, increasing the chance of blade wander. A simple test cut can help verify that the machine holds material correctly.

Workshops that operate both a CNC full automatic High speed circular sawing machine and a metal cutting band sawing machine often notice that stability in long-term band saw operation depends heavily on maintenance habits rather than equipment age alone. Many technicians focus only on blade replacement, yet a band sawing machine requires broader and more consistent care to maintain steady performance. Understanding these maintenance areas helps users prevent unexpected issues and keep the machine running smoothly during daily cutting tasks. Blade Condition Directly Affects Cutting Stability A worn, chipped, or improperly tensioned blade can cause vibration, uneven cutting surfaces, or deviations in length. Technicians should check the blade teeth regularly, especially when the machine handles harder materials.Correct blade tension helps keep the blade on track and reduces sideways movement. Some operators adjust tension only when noticing noise or surface inconsistencies, but checking tension before each shift provides a clearer baseline. If the workshop uses different blade widths for different tasks, confirming that each blade matches the machine’s tension range helps avoid unnecessary strain on the wheel system. Lubrication Helps Maintain Smooth Movement Lubrication is essential for the saw blade guide system, moving components, and bearings. Without regular lubrication, friction increases, which can create unstable cutting and unnecessary machine wear. Applying appropriate lubricant at recommended intervals helps keep the blade moving consistently through the guide arms.Coolant is another area often overlooked. A steady coolant flow keeps the blade temperature under control and supports more uniform cutting. When coolant passages become partially blocked, the blade may heat unevenly, affecting straightness. Operators should check coolant levels, filter screens, and nozzle direction to ensure a smooth, uninterrupted flow. Regular Alignment Checks Support Accurate Cutting Paths Misalignment can develop slowly as the machine experiences daily vibration and heavy workloads. When the band wheels, guide arms, or worktable drift out of alignment, the blade may wander during cutting. This does not always show immediate symptoms, but over time it affects cut accuracy and results in more material waste.Periodic checks of wheel alignment, guide arm parallelism, and vise positioning help technicians identify early signs of drift. Correcting small alignment deviations early prevents larger performance issues. For workshops using both circular sawing machines and band saws, maintaining alignment ensures that both machines produce consistent workpiece lengths, allowing them to complement each other without introducing dimensional differences. Cleaning Routines Reduce Build-Up That Affects Stability Metal chips and dust gradually accumulate around the blade path, drive wheels, and coolant system. Over time, these small particles can interfere with guide movement or cause unnecessary friction. A simple cleaning routine at the end of each shift can help prevent build-up in the machine’s moving areas.Removing chips from the blade gullets also matters. When gullets fill with debris, the blade may not clear chips efficiently, which can cause rough cutting or chatter. A clean machine is not only easier to inspect but also maintains more predictable cutting behavior. Checking the Drive System Helps Maintain Steady Power Transmission The drive belt, motor, and transmission components influence how smoothly power is delivered to the blade. If a belt starts slipping or develops cracks, the blade speed may fluctuate. These small fluctuations can affect cut quality, especially during long work cycles.Routine inspections of belt tension, motor temperature, and pulleys help technicians identify developing issues early. Replacing worn belts or tightening loose connections supports a more consistent cutting motion and reduces the chance of sudden performance drops during production. Hydraulic System Maintenance Supports Stable Clamping For band saws equipped with hydraulic tensioning or clamping systems, hydraulic health is essential. Low fluid levels, aging fluid, or worn seals can reduce clamping force. When the workpiece is not held firmly, vibration increases and the blade may drift during cutting.Technicians should monitor fluid condition and ensure that hoses and seals remain intact. Stable clamping is especially important when cutting heavy or solid stock, where any movement affects both accuracy and safety. Guide Arm and Vise Adjustments Influence Blade Tracking Guide arms keep the blade stable as it enters and exits the workpiece. If the guides sit too far from the material, the blade may be allowed to flex. If set too close, friction increases. Finding the correct spacing is essential for smooth cutting.The vise should also close uniformly and apply even pressure. Uneven clamping forces can tilt the workpiece, increasing the chance of blade wander. A simple test cut can help verify that the machine holds material correctly.

READ MORE

READ MORE

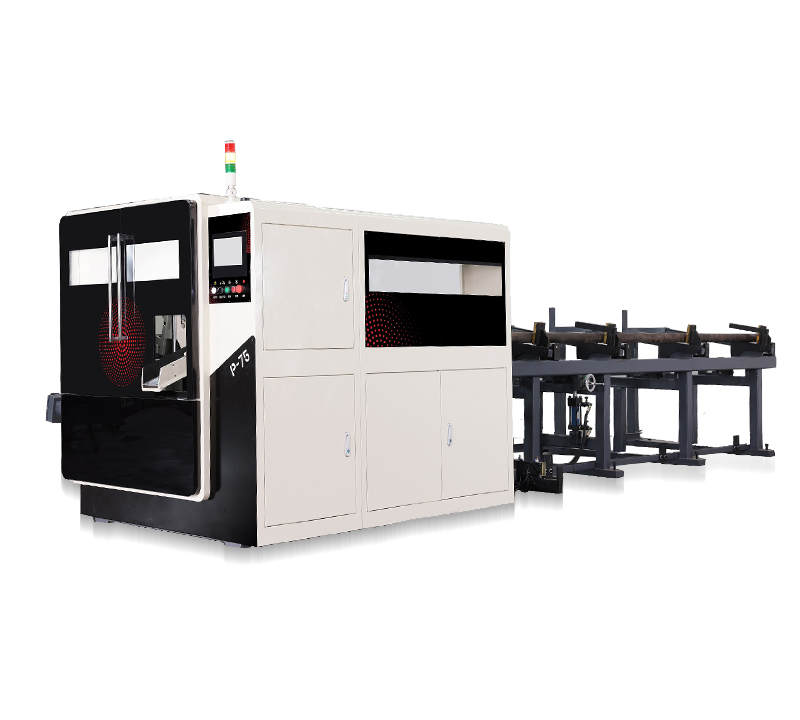

Discussions around equipment upgrades often arise when workshops compare a CNC full automatic high speed circular sawing machine with a metal cutting band sawing machine. Many production teams want to understand why more facilities begin introducing CNC automatic circular saws into their existing workflows, especially when they already operate traditional band sawing equipment. By examining common challenges in metal processing, users can better evaluate whether such an upgrade suits their daily operations. Automation Helps Simplify Repetitive Cutting Tasks Many workshops handle large batches of identical workpieces. Under traditional manual or semi-automatic cutting, operators must repeatedly measure, position, and feed materials. These repeated steps increase the chance of inconsistent dimensions and unplanned scrap.A CNC full automatic circular sawing machine reduces this manual involvement by allowing operators to set cutting parameters once and let the system run. Automatic feeding and positioning support stable production, particularly during long shifts. Shops that run large orders or standardized components often report that this automation helps maintain consistent lengths without requiring frequent adjustments. Cutting Accuracy Supports Dimensional Consistency Dimensional accuracy is one of the core reasons workshops consider upgrading. While a metal cutting band sawing machine can deliver steady results for many materials, circular saws with CNC control offer a more precise path and a narrower range of deviation when cutting round bars, square bars, or tubes.When the blade moves along a fixed track with uniform force, the resulting cut length becomes easier to control. This helps workshops reduce secondary trimming and re-cutting. Users processing parts requiring tight tolerance ranges—such as components for fittings, inserts, or mechanical hardware—often find that the dimensional consistency of CNC circular sawing aligns better with their production needs. High-Speed Cutting Improves Throughput for Certain Materials Circular sawing machines are designed for fast cutting cycles, especially when dealing with solid bars or harder alloys. Their cutting motion differs from band saws, allowing them to complete each cut in a shorter time. For workshops facing tight delivery schedules or high volumes, reducing individual cycle time can support smoother workflow planning.This does not mean circular sawing replaces band sawing in all applications. Band saws remain useful for large sections, structural shapes, or special profiles. However, for users focusing on repetitive straight cuts, switching to a high-speed circular saw can help them handle more pieces within the same working hours. Surface Quality Supports Downstream Processes When the cutting surface is smoother, downstream machining steps—such as turning, milling, or polishing—may require less correction. A CNC full automatic high speed circular sawing machine often delivers a cleaner finish compared with some types of band sawing operations, especially for dense materials.Workshops that supply semi-finished parts to CNC machining centers often appreciate this improved surface condition. Less material removal means shorter machining times, which can help reduce tool wear and stabilize processing schedules. Reduced Human Error Helps Maintain Uniform Output One of the overlooked sources of production deviation is human error. Even experienced operators occasionally produce inconsistent results when manually feeding material or adjusting clamping positions. Fatigue during long shifts can further influence accuracy.CNC-controlled equipment reduces the need for these repeated manual steps. The machine’s automatic clamping, measuring, and feeding functions maintain a predictable pattern. For workshops with varying operator skill levels, this feature contributes to more uniform output without relying heavily on individual expertise. Safety Features Support More Stable Daily Operation Safety devices such as protective shields, emergency stop buttons, and overload detection help create a more secure working environment. These features protect operators and also safeguard materials during unexpected conditions. When equipment stops promptly during abnormal operation, it prevents damaged cuts or unusable workpieces that would otherwise need to be discarded.Workshops that frequently rotate operators or employ new staff often value this added layer of protection. Safety-oriented control helps maintain production quality while allowing workers to operate the machine with confidence. Material Utilization Improves Through Accurate Cutting Layouts The way raw materials are consumed directly affects workshop cost control. If the cut lengths vary, leftover segments may be too short for the next order. CNC circular sawing machines support more predictable cut lengths, making it easier for operators to plan bar usage and arrange cutting lists.

Discussions around equipment upgrades often arise when workshops compare a CNC full automatic high speed circular sawing machine with a metal cutting band sawing machine. Many production teams want to understand why more facilities begin introducing CNC automatic circular saws into their existing workflows, especially when they already operate traditional band sawing equipment. By examining common challenges in metal processing, users can better evaluate whether such an upgrade suits their daily operations. Automation Helps Simplify Repetitive Cutting Tasks Many workshops handle large batches of identical workpieces. Under traditional manual or semi-automatic cutting, operators must repeatedly measure, position, and feed materials. These repeated steps increase the chance of inconsistent dimensions and unplanned scrap.A CNC full automatic circular sawing machine reduces this manual involvement by allowing operators to set cutting parameters once and let the system run. Automatic feeding and positioning support stable production, particularly during long shifts. Shops that run large orders or standardized components often report that this automation helps maintain consistent lengths without requiring frequent adjustments. Cutting Accuracy Supports Dimensional Consistency Dimensional accuracy is one of the core reasons workshops consider upgrading. While a metal cutting band sawing machine can deliver steady results for many materials, circular saws with CNC control offer a more precise path and a narrower range of deviation when cutting round bars, square bars, or tubes.When the blade moves along a fixed track with uniform force, the resulting cut length becomes easier to control. This helps workshops reduce secondary trimming and re-cutting. Users processing parts requiring tight tolerance ranges—such as components for fittings, inserts, or mechanical hardware—often find that the dimensional consistency of CNC circular sawing aligns better with their production needs. High-Speed Cutting Improves Throughput for Certain Materials Circular sawing machines are designed for fast cutting cycles, especially when dealing with solid bars or harder alloys. Their cutting motion differs from band saws, allowing them to complete each cut in a shorter time. For workshops facing tight delivery schedules or high volumes, reducing individual cycle time can support smoother workflow planning.This does not mean circular sawing replaces band sawing in all applications. Band saws remain useful for large sections, structural shapes, or special profiles. However, for users focusing on repetitive straight cuts, switching to a high-speed circular saw can help them handle more pieces within the same working hours. Surface Quality Supports Downstream Processes When the cutting surface is smoother, downstream machining steps—such as turning, milling, or polishing—may require less correction. A CNC full automatic high speed circular sawing machine often delivers a cleaner finish compared with some types of band sawing operations, especially for dense materials.Workshops that supply semi-finished parts to CNC machining centers often appreciate this improved surface condition. Less material removal means shorter machining times, which can help reduce tool wear and stabilize processing schedules. Reduced Human Error Helps Maintain Uniform Output One of the overlooked sources of production deviation is human error. Even experienced operators occasionally produce inconsistent results when manually feeding material or adjusting clamping positions. Fatigue during long shifts can further influence accuracy.CNC-controlled equipment reduces the need for these repeated manual steps. The machine’s automatic clamping, measuring, and feeding functions maintain a predictable pattern. For workshops with varying operator skill levels, this feature contributes to more uniform output without relying heavily on individual expertise. Safety Features Support More Stable Daily Operation Safety devices such as protective shields, emergency stop buttons, and overload detection help create a more secure working environment. These features protect operators and also safeguard materials during unexpected conditions. When equipment stops promptly during abnormal operation, it prevents damaged cuts or unusable workpieces that would otherwise need to be discarded.Workshops that frequently rotate operators or employ new staff often value this added layer of protection. Safety-oriented control helps maintain production quality while allowing workers to operate the machine with confidence. Material Utilization Improves Through Accurate Cutting Layouts The way raw materials are consumed directly affects workshop cost control. If the cut lengths vary, leftover segments may be too short for the next order. CNC circular sawing machines support more predictable cut lengths, making it easier for operators to plan bar usage and arrange cutting lists.

READ MORE

READ MORE