In the industrial world, bandsaws are essential tools for cutting metal, wood, and other materials with precision. Among the various types of bandsaws available, vertical and horizontal models are particularly prominent, each offering distinct advantages and applications. This article explores the differences between vertical and horizontal bandsaws, their unique benefits, and how they are used across various industries to achieve cutting results.

Vertical bandsaws and horizontal bandsaws are designed to handle cutting tasks in different orientations, which significantly influences their use and effectiveness in various applications.

Vertical bandsaws are characterized by their upright design, where the blade runs vertically. This configuration allows for intricate cutting and contouring, making them ideal for detailed work. Vertical bandsaws are typically used for cutting irregular shapes, curves, and smaller pieces of material. Their design also facilitates the use of a larger worktable, which supports the material being cut and provides stability during the operation.

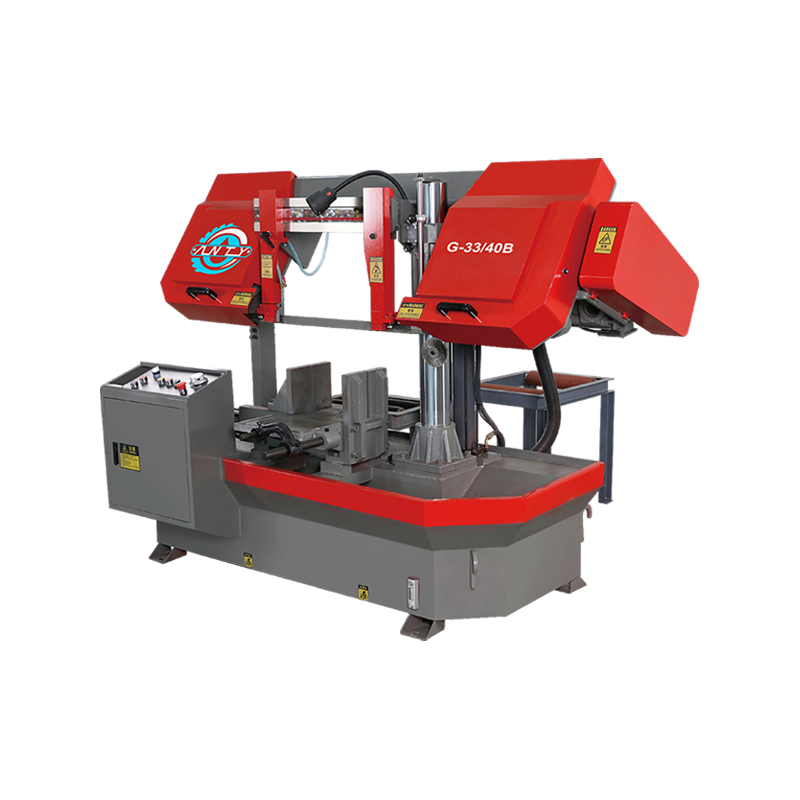

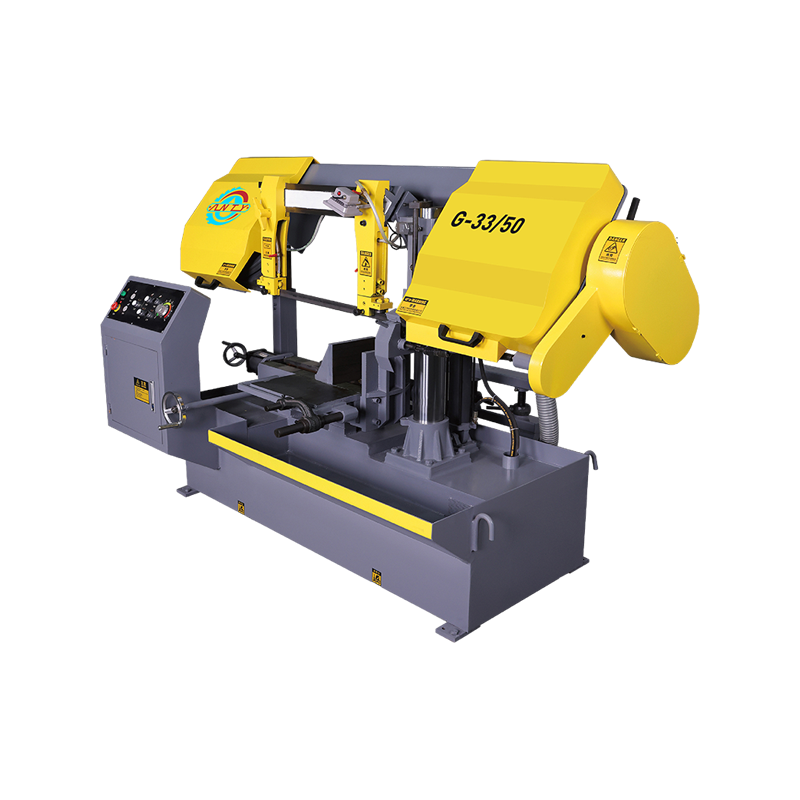

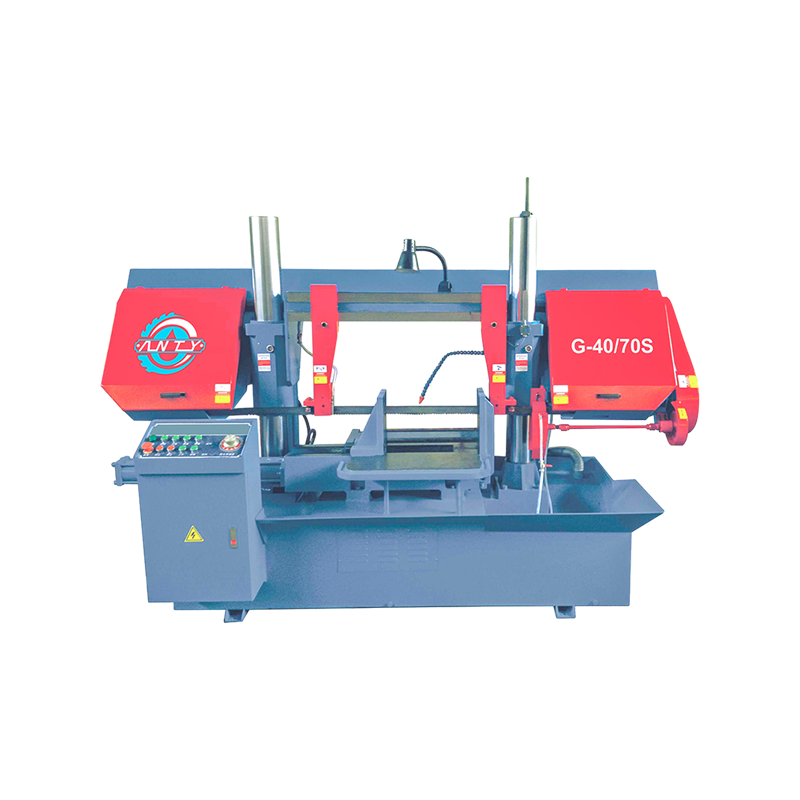

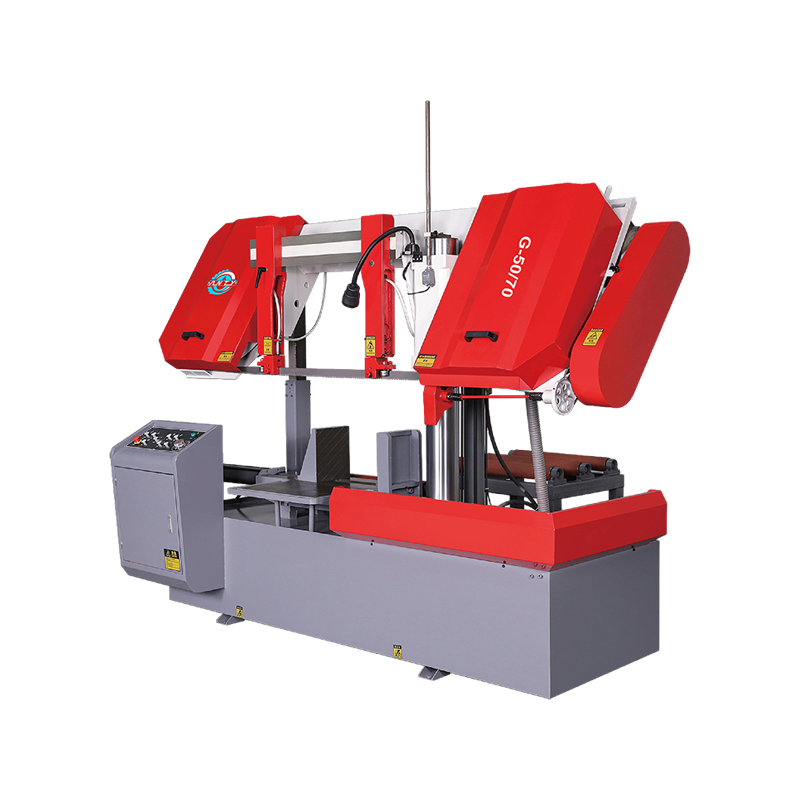

In contrast, horizontal bandsaws are oriented with the blade running horizontally. This setup is particularly effective for cutting larger pieces of material, such as metal bars or beams, into manageable sizes. Horizontal bandsaws are commonly used for straight cuts and can handle larger volumes of material with efficiency. They are equipped with a gravity-fed mechanism or a hydraulic system that helps feed the material through the blade, ensuring consistent and precise cuts.

Vertical bandsaws offer several advantages that make them suitable for specific cutting tasks:

Precision Cutting: Vertical bandsaws are renowned for their ability to make precise and detailed cuts. This is particularly useful in industries that require intricate shapes and curves, such as woodworking, aerospace, and custom fabrication. The vertical orientation allows for more control and accuracy in cutting complex patterns.

Versatility: The adjustable blade guides and large worktable of vertical bandsaws enable users to handle a variety of materials and cutting tasks. They are ideal for cutting irregularly shaped pieces and performing resawing operations, where thicker materials are sliced into thinner sections.

Ease of Use: The upright design of vertical bandsaws makes them accessible and user-friendly for detailed work. Operators can easily position and maneuver the material, facilitating more intricate and controlled cutting processes.

Horizontal bandsaws also offer unique benefits that make them valuable in different scenarios:

Efficiency: Horizontal bandsaws are designed for cutting larger volumes of material quickly and efficiently. The gravity-fed mechanism or hydraulic system ensures a smooth and consistent feed, allowing for high-speed cutting of metal bars, pipes, and beams. This efficiency is crucial in industrial settings where productivity and throughput are important.

Durability: These saws are built to handle heavy-duty cutting tasks and are often constructed with robust materials and components. This durability ensures that horizontal bandsaws can withstand the rigors of cutting hard materials and maintain performance over time.

Consistent Cuts: The horizontal orientation of the bandsaw allows for uniform cutting across large pieces of material. This consistency is essential for applications that require precise dimensions and repeatability, such as in metal fabrication and construction.

The choice between vertical and horizontal bandsaws largely depends on the specific cutting needs and the type of material being processed.

Vertical bandsaws are frequently used in industries where detailed and intricate cutting is required. For example:

Woodworking: Vertical bandsaws are used for cutting complex wood shapes and curves, making them ideal for custom furniture and decorative pieces.

Aerospace: Precision cutting of metal components and intricate shapes for aircraft and spacecraft is often performed with vertical bandsaws.

Fabrication: In metal fabrication shops, vertical bandsaws are employed for custom cuts and adjustments, including the creation of prototypes and small-batch production.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US