The metalworking industry continues to evolve with new technologies and innovations that improve precision, efficiency, and versatility in cutting processes. Among the impactful tools in this sector are horizontal vertical bandsaws, a versatile machine that has redefined the way metal is cut in various industrial applications. These bandsaws have gained significant attention for their dual functionality, offering the advantages of both horizontal and vertical cutting, and providing increased flexibility for professionals across multiple fields.

In this article, we will explore how horizontal vertical bandsaws are changing the landscape of the metalworking industry, highlighting their key features, applications, and the reasons behind their growing popularity.

For decades, bandsaws have been a staple in metalworking, woodworking, and various other industries. Traditionally, these saws were divided into two categories: horizontal bandsaws, which are primarily used for cutting long metal pieces like pipes, rods, and beams; and vertical bandsaws, which are often used for more intricate cutting tasks that require a higher degree of precision. The development of horizontal vertical bandsaws combines the strengths of both types, giving metalworkers the of both worlds in one machine.

The demand for more flexible, multipurpose tools has driven the popularity of horizontal vertical bandsaws in recent years. Manufacturers have recognized that workshops, job sites, and factories need machines that can perform a variety of tasks without requiring constant changes to the setup. The ability to switch between horizontal and vertical cutting on a single machine allows workers to handle different cutting operations efficiently and with minimal downtime.

Several key features set horizontal vertical bandsaws apart from traditional bandsaws, making them a valuable asset in any workshop or manufacturing environment. These features include:

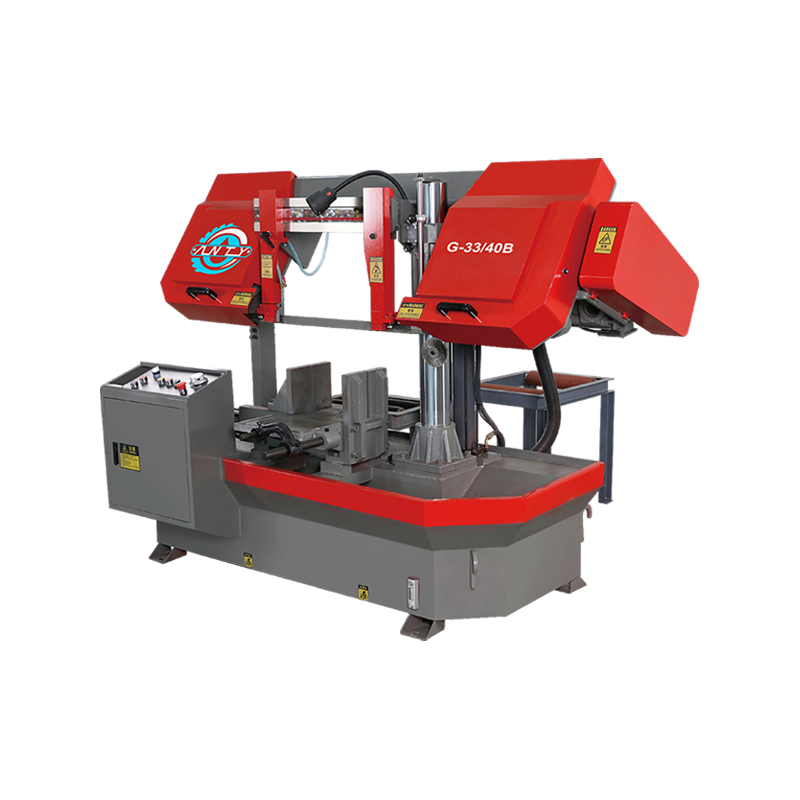

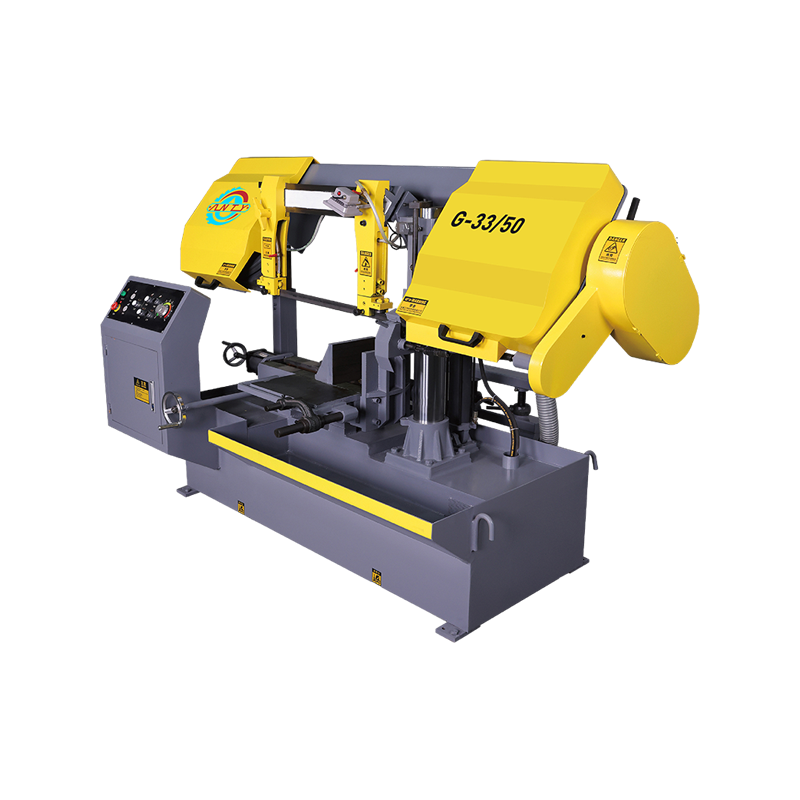

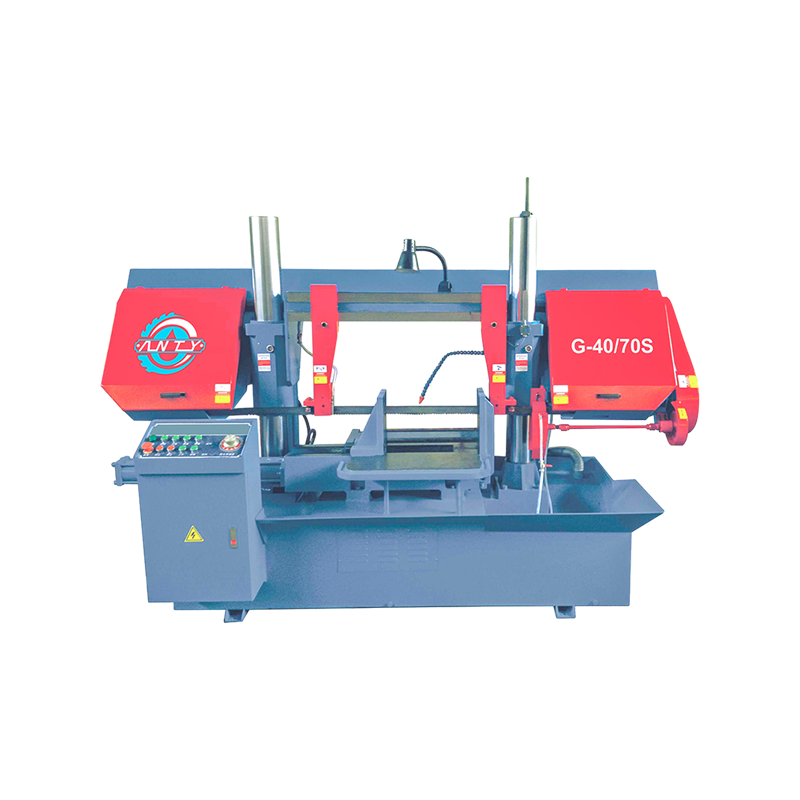

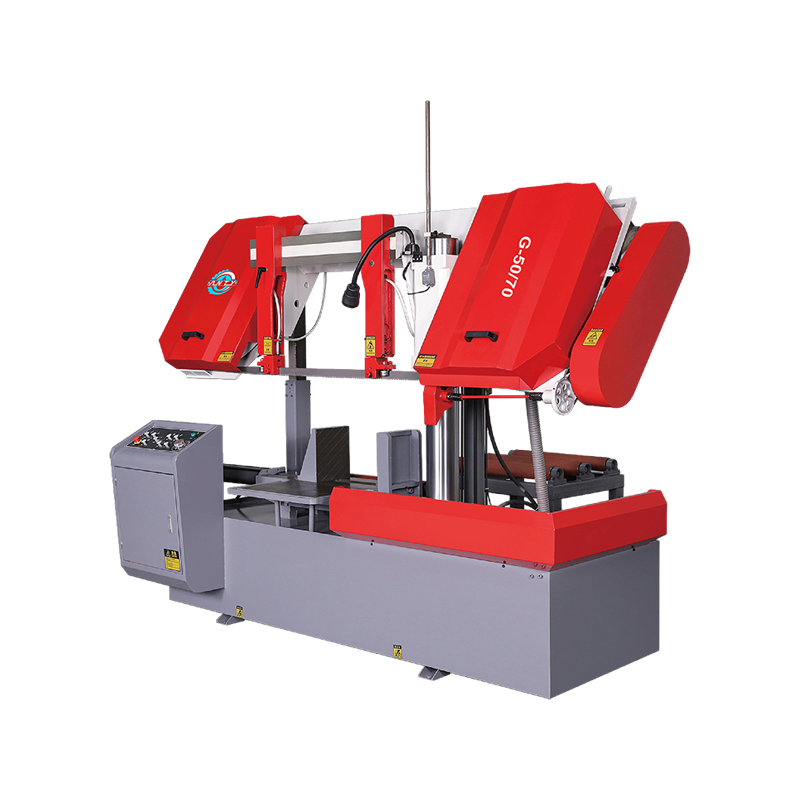

The significant advantage of horizontal vertical bandsaws is their ability to switch between horizontal and vertical cutting modes. In horizontal mode, the saw excels at making straight cuts through long metal pieces, making it ideal for cutting stock materials like rods, tubes, and bars. In vertical mode, the bandsaw can handle more intricate, curved, or irregular cuts, allowing for greater versatility in shaping metal components.

To accommodate a wide variety of materials, many horizontal vertical bandsaws come equipped with adjustable blade speed controls. This feature allows operators to adjust the speed depending on the material they are cutting, whether it's steel, aluminum, or softer metals. Being able to control the blade speed ensures smoother cuts and reduces the wear and tear on the machine.

Both horizontal and vertical bandsaws are known for their precision, and horizontal vertical bandsaws take this a step further by offering the ability to make accurate cuts in a variety of positions. Whether the task involves straight cuts or intricate designs, the precision offered by these machines minimizes material waste and ensures cleaner edges, reducing the need for post-cut processing.

Space is often a premium in workshops and manufacturing floors, and horizontal vertical bandsaws offer the advantage of consolidating two machines into one. Instead of having separate horizontal and vertical bandsaws, metalworkers can save space by utilizing a single machine capable of performing both functions. This compact design is ideal for smaller shops or busy industrial floors where optimizing space is essential.

Built with heavy-duty materials and designed to handle the rigors of industrial environments, horizontal vertical bandsaws are known for their durability. These machines can withstand continuous use, cutting through tough materials like stainless steel and cast iron without compromising performance. Their long lifespan makes them a sound investment for businesses looking to increase productivity over the long term.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US