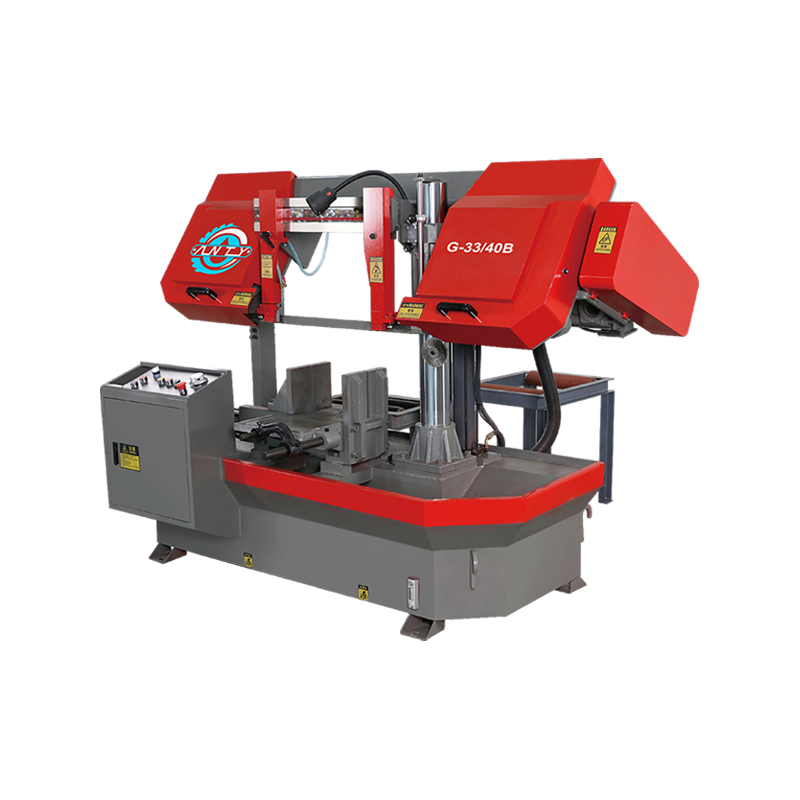

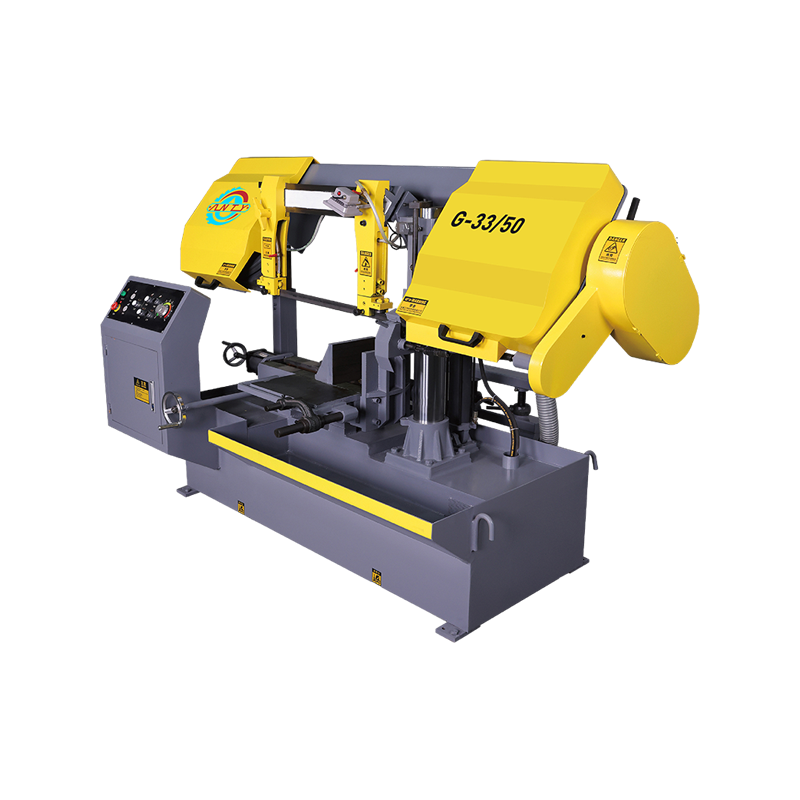

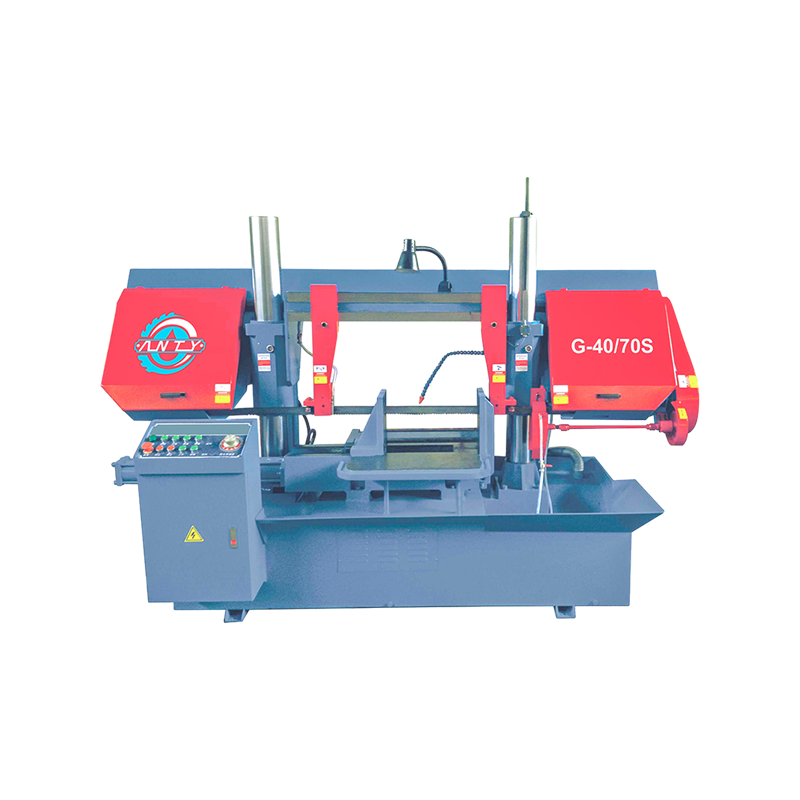

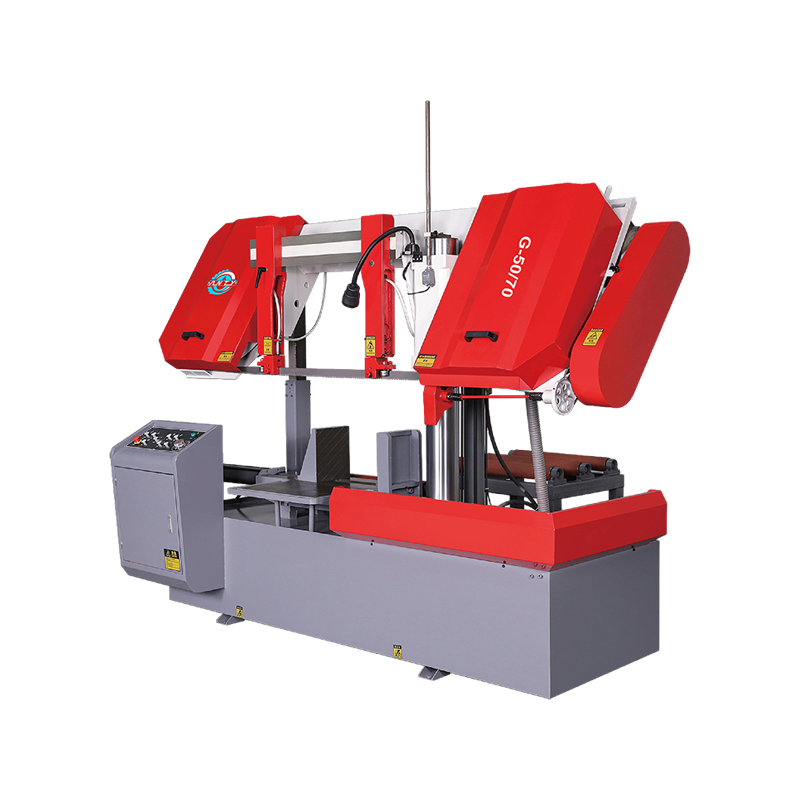

In the ever-evolving landscape of metalworking technology, the CNC Automatic Angle Metal Band Saw Machine emerges as a game-changer, promising unparalleled precision and efficiency in cutting operations. This advanced machine, equipped with cutting-edge CNC capabilities, is poised to revolutionize the way manufacturers approach metal fabrication, setting new benchmarks for quality and productivity.

Manufactured by industry-leading experts in CNC machinery, this state-of-the-art Metal Band Saw Machine represents the pinnacle of engineering excellence. With its advanced computer numerical control (CNC) system, operators can program complex cutting sequences with precision, ensuring consistent and accurate results with every operation.

The CNC Automatic Angle Metal Band Saw Machine offers a level of versatility that is unmatched in traditional metal cutting methods. Whether it's straight cuts, bevel cuts, or intricate angles, this machine can effortlessly handle a wide range of cutting tasks, catering to the diverse needs of modern manufacturing applications.

One of the key advantages of this machine lies in its ability to optimize material usage and minimize waste. By precisely controlling cutting parameters such as blade speed, feed rate, and cutting angles, manufacturers can maximize the yield from raw materials while reducing scrap, ultimately leading to significant cost savings and improved efficiency.

Furthermore, the CNC Automatic Angle Metal Band Saw Machine is designed to enhance operator safety and minimize human error. With automated features such as blade monitoring systems and collision detection sensors, the risk of accidents and work-related injuries is greatly reduced, ensuring a safe working environment for personnel.

In addition to its cutting-edge technology, this machine boasts robust construction and durable components, ensuring reliable performance even in the most demanding production environments. Its ability to deliver consistent, high-quality cuts makes it an indispensable asset for industries ranging from automotive and aerospace to construction and beyond.

The CNC Automatic Angle Metal Band Saw Machine is not just a tool; it's a strategic investment for manufacturers looking to stay ahead of the competition. Its ability to streamline production processes, reduce lead times, and improve overall product quality gives businesses a competitive edge in today's fast-paced market landscape.

With the CNC Automatic Angle Metal Band Saw Machine now available for sale, manufacturers have the opportunity to upgrade their metalworking capabilities and unlock new levels of efficiency and productivity. Whether it's optimizing existing workflows or exploring new opportunities for innovation, this machine opens up a world of possibilities for forward-thinking businesses.

As industries continue to evolve and adapt to changing market dynamics, the demand for advanced manufacturing technologies like the CNC Automatic Angle Metal Band Saw Machine is expected to soar. Its ability to deliver superior performance, combined with its versatility and precision, makes it a must-have tool for manufacturers striving to meet the demands of today's competitive marketplace.

The CNC Automatic Angle Metal Band Saw Machine represents a paradigm shift in metal fabrication technology. Its advanced CNC capabilities, coupled with unmatched precision and efficiency, redefine the standards of excellence in the industry. As businesses embrace this transformative technology, they are poised to achieve new heights of success and competitiveness in the global marketplace.

With the CNC Automatic Angle Metal Band Saw Machine rapidly gaining traction in the manufacturing sector, its impact on various industries is becoming increasingly evident. From small-scale workshops to large-scale production facilities, businesses are leveraging the capabilities of this cutting-edge machine to drive innovation, improve efficiency, and enhance overall competitiveness.

One of the most significant advantages of the CNC Automatic Angle Metal Band Saw Machine is its ability to adapt to evolving production requirements. With its intuitive programming interface and flexible automation features, operators can easily adjust cutting parameters on the fly, allowing for quick setup changes and seamless transition between different production runs.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US