In the realm of metalworking, precision and efficiency are key. The horizontal metal cutting band saw has emerged as a critical tool in achieving these objectives. This article will discuss the latest advancements in horizontal metal cutting band saw technology, its impact on the manufacturing industry, and why it's becoming indispensable for businesses looking to stay competitive.

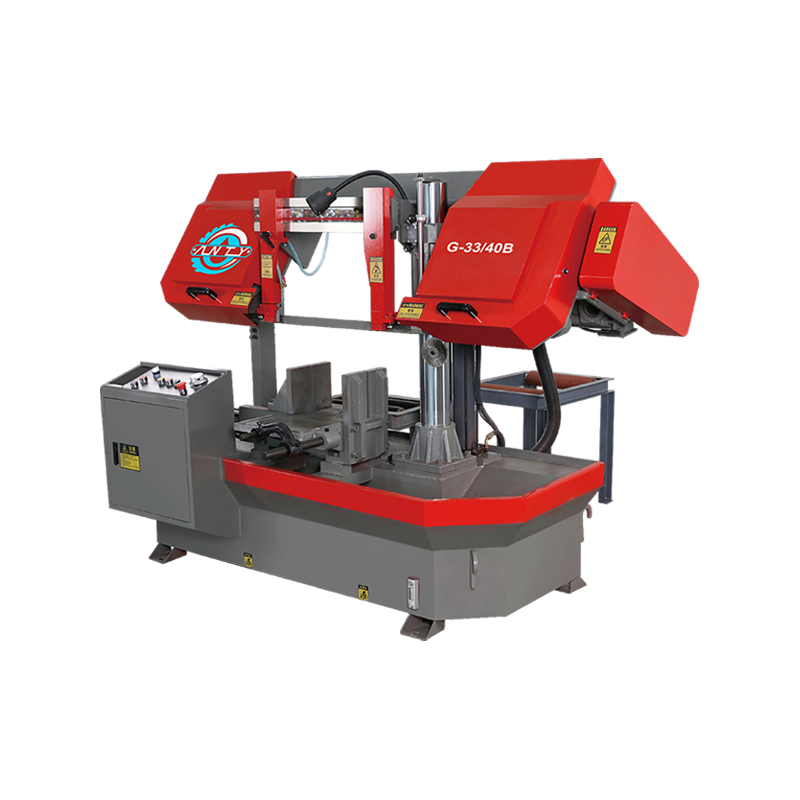

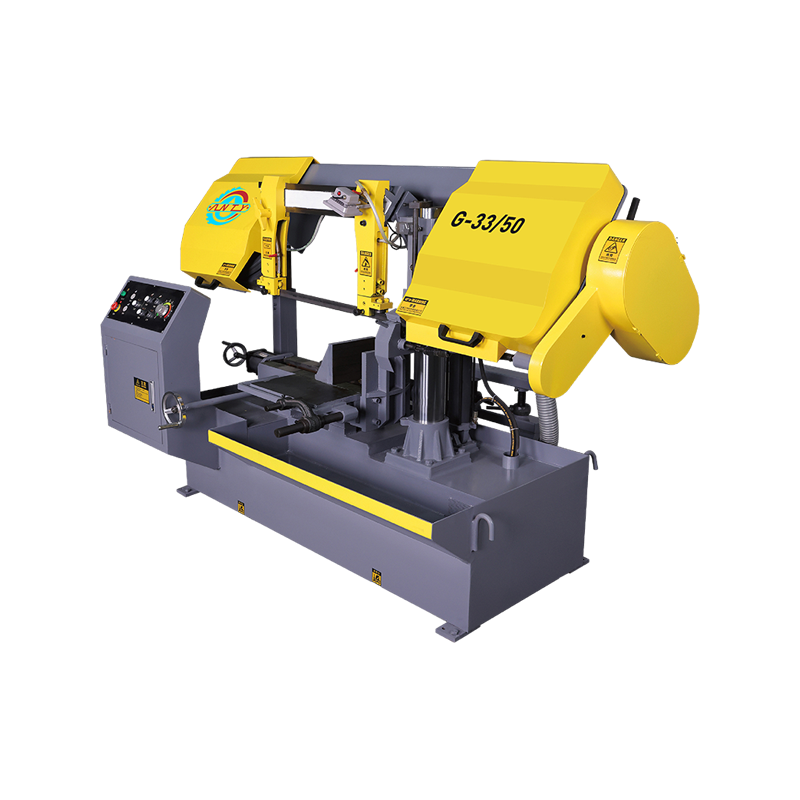

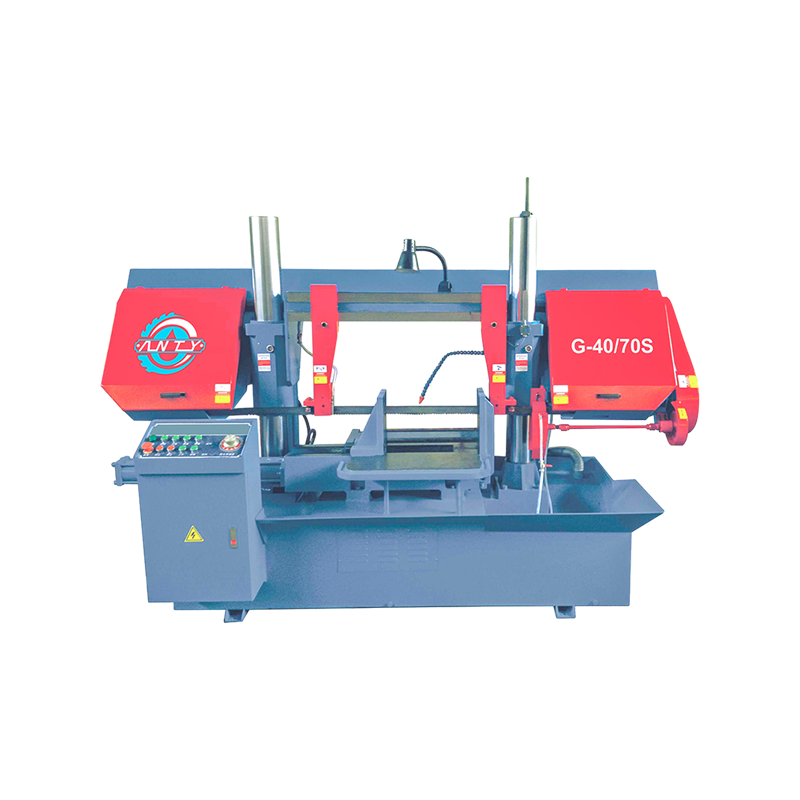

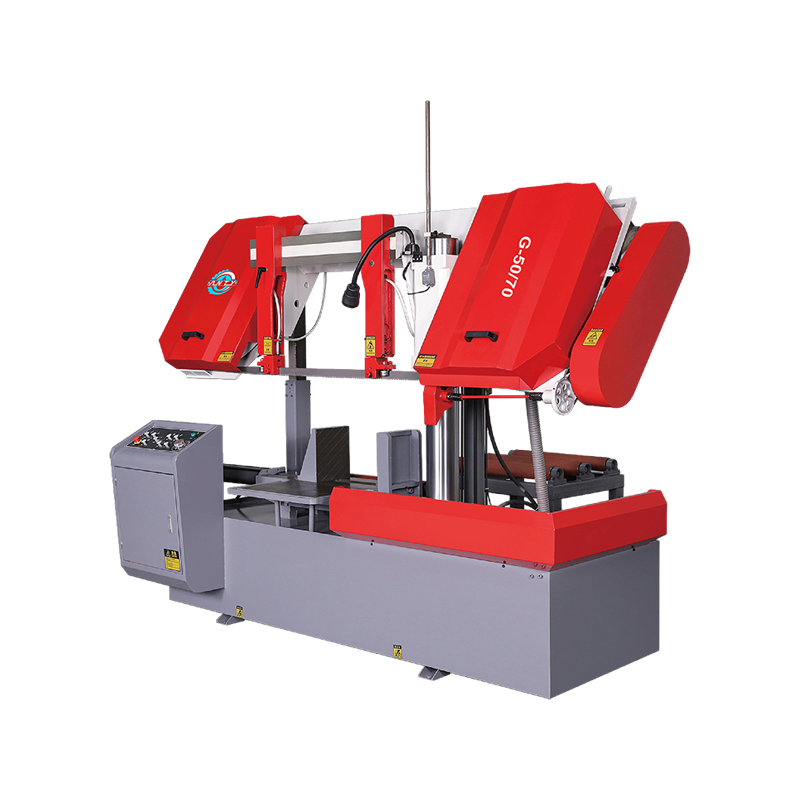

The horizontal metal cutting band saw has come a long way since its inception. Originally designed for simple metal cutting tasks, today's models are equipped with advanced features that make them versatile and indispensable in various manufacturing processes.

Features of the Modern Horizontal Metal Cutting Band Saw:

1. Precision Cutting: The horizontal metal cutting band saw is known for its ability to make clean, precise cuts with minimal material loss. This is crucial in industries where material cost is a significant factor.

2. Versatility: With the ability to cut a wide range of metal thicknesses and types, the horizontal metal cutting band saw is a one-stop solution for various cutting needs.

3. Safety: Modern horizontal metal cutting band saws are designed with safety in mind, incorporating features such as blade guards and emergency stop buttons to protect operators.

4. Efficiency: The horizontal design allows for continuous cutting without the need to reposition the material, which significantly increases productivity.

5. Durability: High-quality materials and robust construction ensure that horizontal metal cutting band saws can withstand the rigors of industrial use.

The Impact on the Manufacturing Industry:

The adoption of horizontal metal cutting band saws has had a profound impact on the manufacturing industry. Here's how:

1. Increased Productivity: The continuous cutting capability of the horizontal metal cutting band saw allows for uninterrupted workflow, to higher output and faster production times.

2. Cost Savings: By reducing material waste and minimizing the need for secondary finishing processes, businesses can save on material and labor costs.

3. Improved Quality: The precision of the horizontal metal cutting band saw results in higher-quality cuts, which can to better end products and increased customer satisfaction.

4. Enhanced Safety: The safety features of modern horizontal metal cutting band saws contribute to a safer working environment, reducing the risk of accidents and associated costs.

5. Environmental Considerations: By minimizing waste, the horizontal metal cutting band saw aligns with the growing trend of sustainability in manufacturing.

Several companies have reported significant benefits after integrating horizontal metal cutting band saws into their operations. For instance, a automotive parts manufacturer reported a 30% increase in productivity and a 20% reduction in material waste after implementing the technology.

Another example is a heavy machinery manufacturer that saw a 40% reduction in cutting time and a 15% decrease in operational costs after upgrading to a horizontal metal cutting band saw.

The horizontal metal cutting band saw is a testament to the ongoing innovation in the manufacturing sector. As businesses continue to seek ways to improve their operations, the adoption of this technology is expected to rise. With its precision, versatility, and efficiency, the horizontal metal cutting band saw is not just a tool—it's a game-changer for the industry.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US