Band sawing machines, a cornerstone of modern cutting technology, are witnessing significant advancements as industries demand more precision, efficiency, and versatility. These machines, essential in sectors ranging from metalworking to woodworking, are evolving to meet the needs of a rapidly changing market. This article explores the latest innovations in band sawing machines, their applications across various industries, and the trends shaping their future.

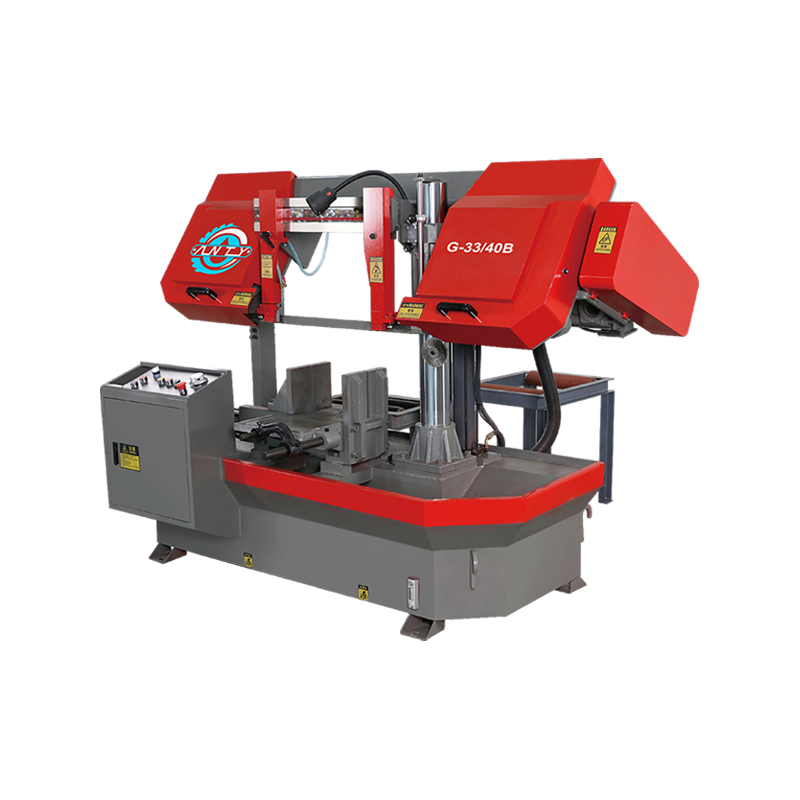

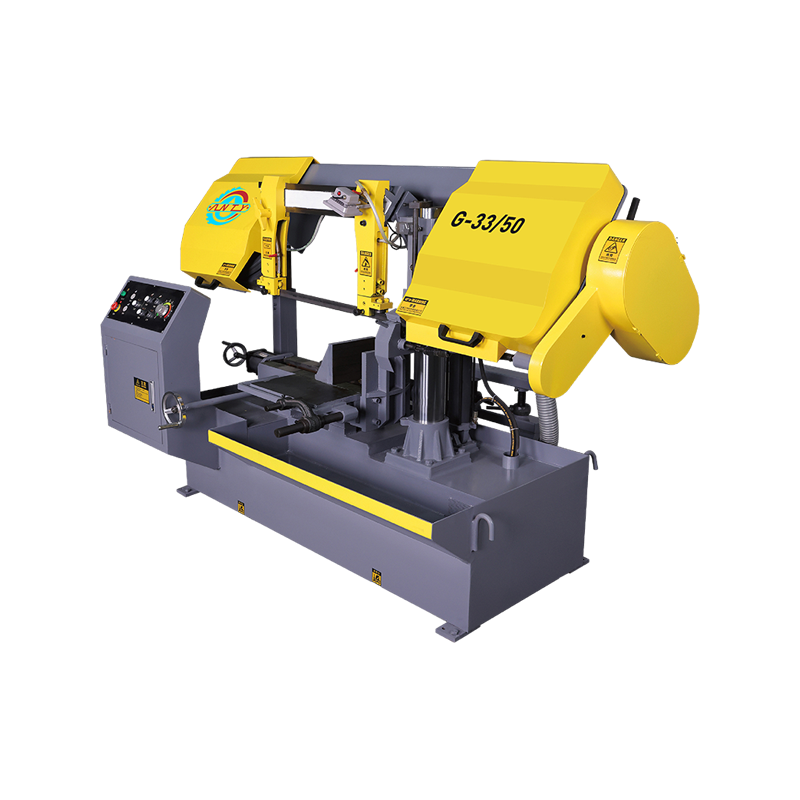

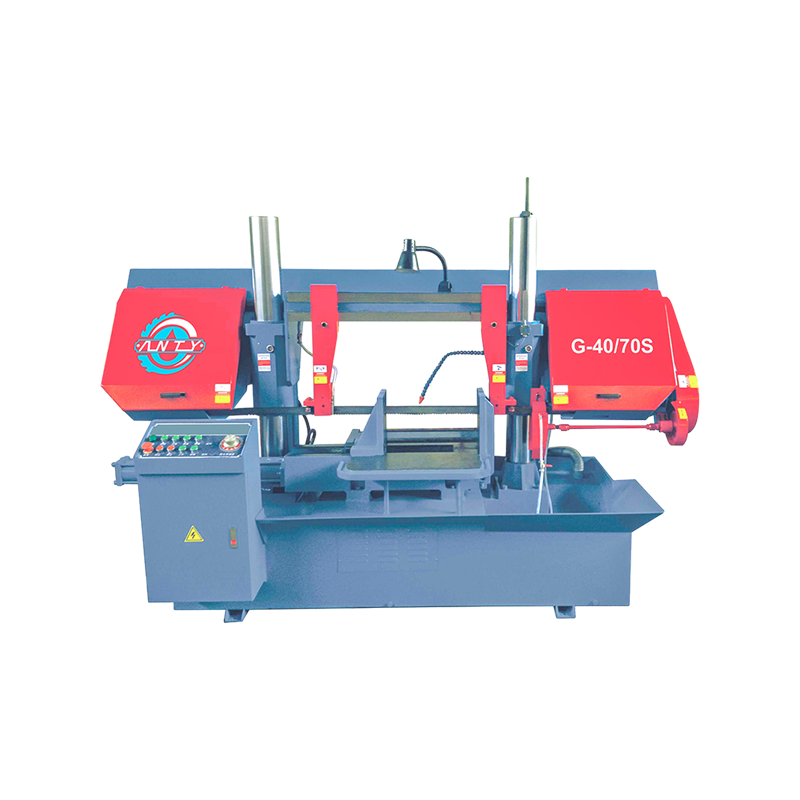

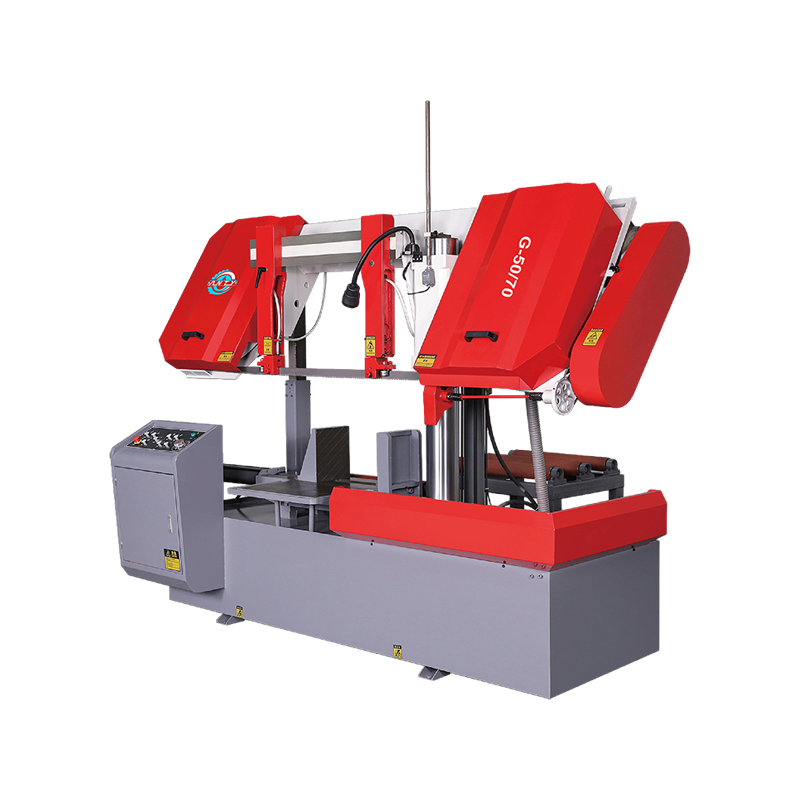

Band sawing machines are renowned for their ability to cut a wide range of materials, including metal, wood, and plastics. These machines use a continuous band of toothed metal to make precise cuts, making them indispensable in manufacturing and construction. The versatility of band sawing machines allows them to handle various cutting tasks, from intricate designs to heavy-duty applications.

In recent years, the demand for band sawing machines has increased as industries seek more efficient and cost-effective cutting solutions. This surge in demand has driven innovation and improvements in machine technology, resulting in enhanced performance and functionality.

Advanced Blade Technologies: One of the notable advancements in band sawing machines is the development of high-performance blades. Modern band saw blades are engineered with materials and coatings that improve durability and cutting precision. Innovations such as carbide-tipped teeth and bi-metal blades extend the lifespan of the blades and enhance cutting efficiency.

Automation and Smart Technology: The integration of automation and smart technology is transforming band sawing machines. Features such as computer numerical control (CNC) and programmable logic controllers (PLC) enable precise and automated cutting operations. These advancements reduce manual labor, minimize errors, and increase production speed.

Enhanced Cooling Systems: Effective cooling systems are crucial for maintaining blade performance and extending its life. Recent improvements in cooling technology, such as advanced coolant delivery systems and temperature sensors, help manage heat more efficiently during cutting operations. This results in better blade performance and reduces the risk of overheating.

Energy Efficiency: As industries become more conscious of their environmental impact, energy-efficient band sawing machines are gaining popularity. Manufacturers are designing machines that consume less power while maintaining high cutting performance. This focus on energy efficiency not only reduces operational costs but also aligns with sustainability goals.

Improved Safety Features: Safety remains a top priority in the design of band sawing machines. Recent models incorporate advanced safety features such as automatic blade guards, emergency stop buttons, and safety interlocks. These enhancements protect operators and reduce the risk of accidents in the workplace.

Band sawing machines are used in a variety of industries, each benefiting from the machine's versatility and precision. Some key applications include:

Metalworking: In metalworking, band sawing machines are used to cut various metals, including steel, aluminum, and stainless steel. Their ability to handle different thicknesses and materials makes them essential in fabricating metal parts and components.

Woodworking: The woodworking industry relies on band sawing machines for cutting lumber, veneers, and intricate designs. These machines are used to create everything from furniture to architectural elements, providing the precision needed for high-quality finishes.

Construction: Band sawing machines play a crucial role in the construction industry, where they are used to cut structural components and materials. Their ability to handle large and heavy materials makes them suitable for various construction applications.

Aerospace and Automotive: In the aerospace and automotive industries, precision is paramount. Band sawing machines are employed to cut components with tight tolerances and high-performance materials, contributing to the production of critical parts and assemblies.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US