In the fast-evolving world of metalworking, the demand for higher precision and greater efficiency continues to grow. Among the essential tools meeting these demands is the horizontal metal cutting band saw. Whether used in heavy manufacturing, construction, or metal fabrication, these saws offer unparalleled performance in cutting through a wide range of metals with incredible accuracy. As industries continue to push for greater automation, the horizontal metal cutting band saw has become a critical piece of equipment in workshops across the globe.

What is a Horizontal Metal Cutting Band Saw?

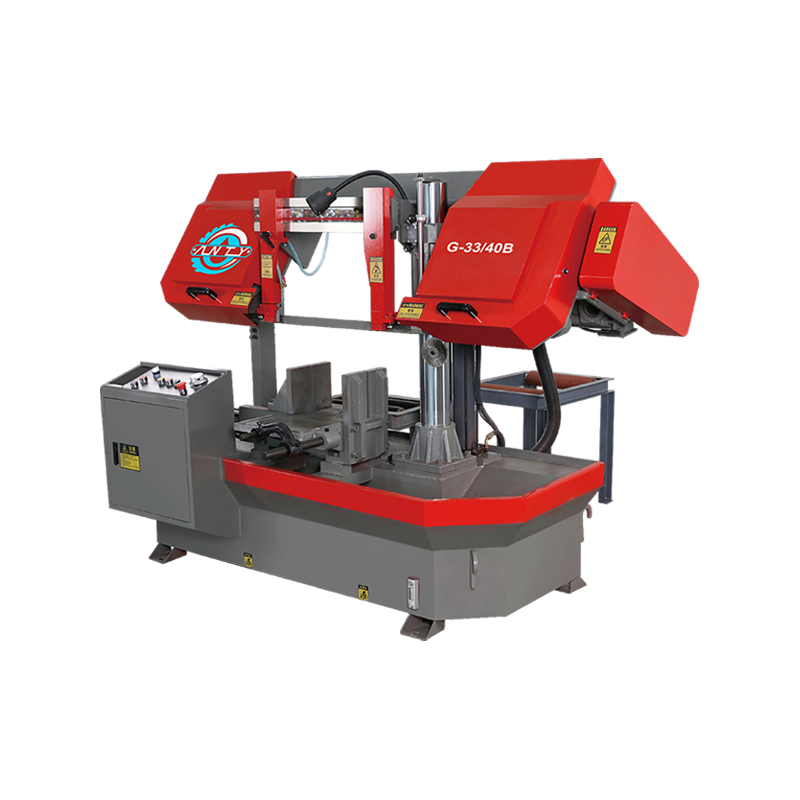

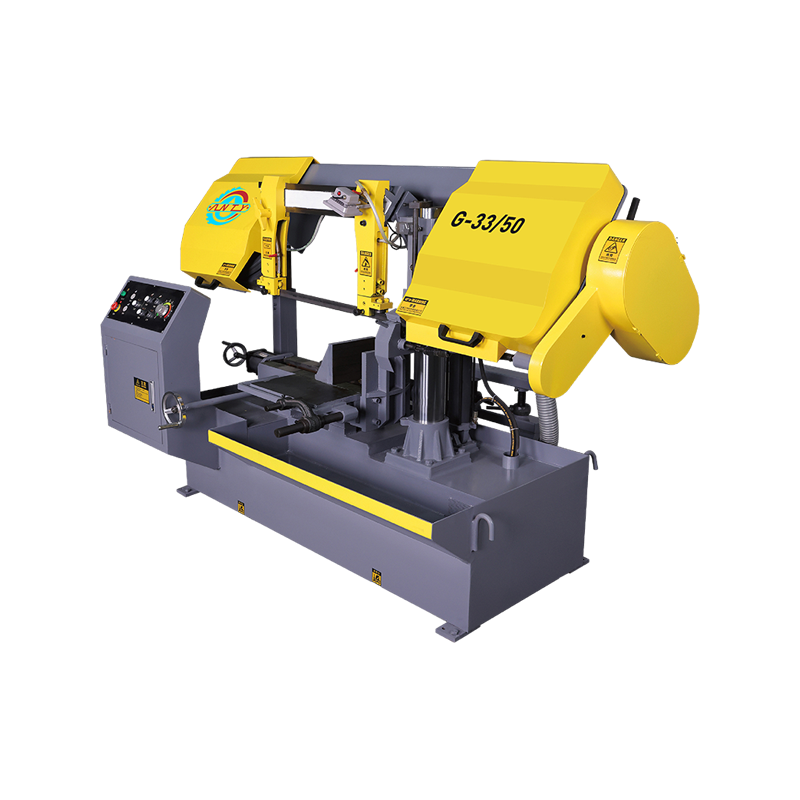

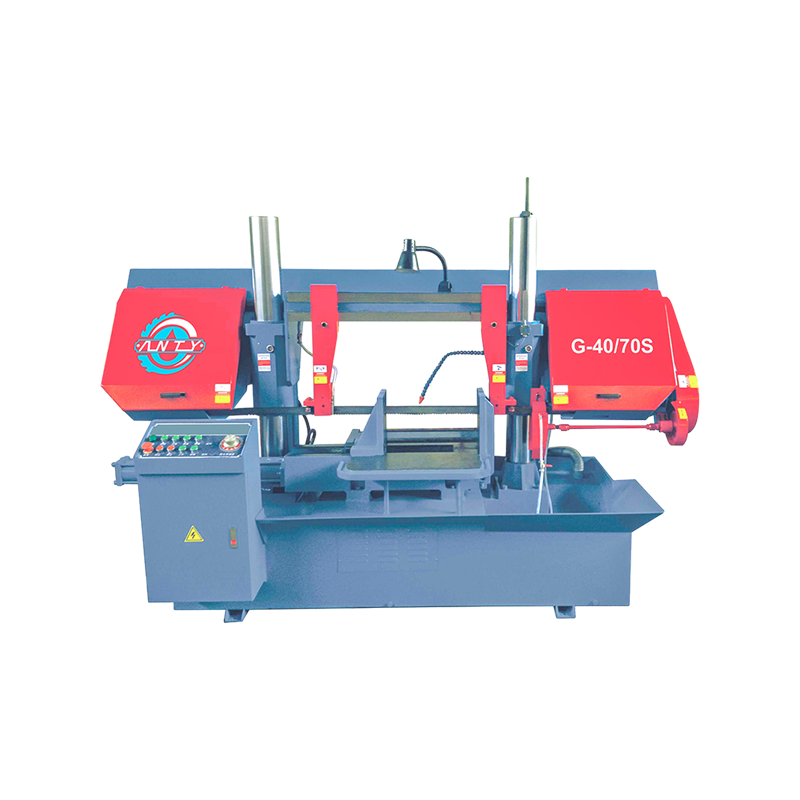

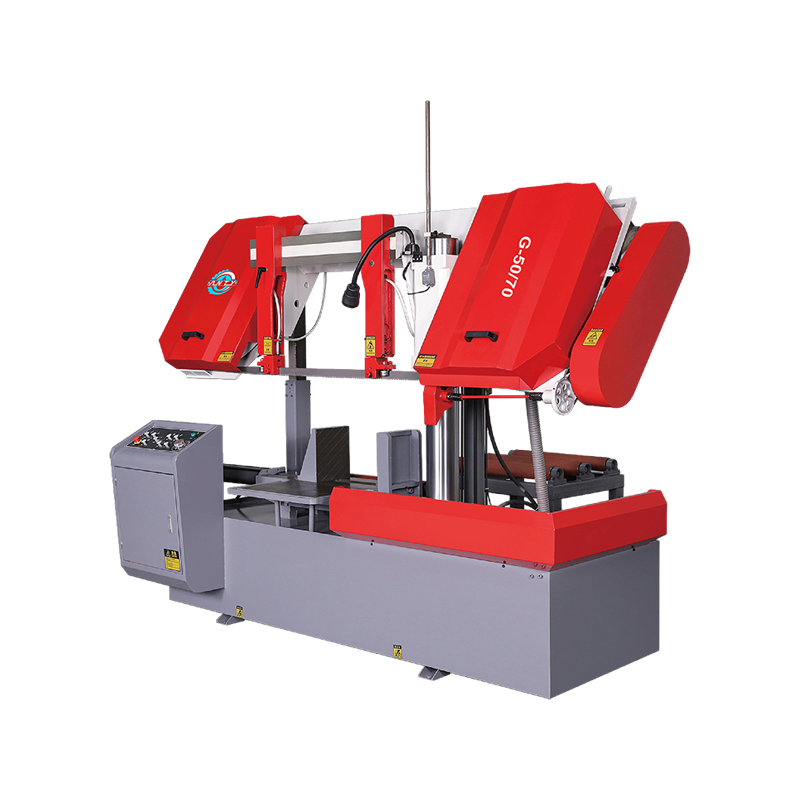

A horizontal metal cutting band saw is a cutting tool used primarily in the metalworking industry to cut large metal pieces into manageable sizes. Unlike vertical band saws, which work on a top-down cutting motion, horizontal metal cutting band saws operate with a horizontal blade that cuts from the side. This design enables the saw to efficiently cut through large pieces of metal, such as pipes, beams, bars, and plates.

The key components of a horizontal metal cutting band saw include a long, continuous band blade that moves over two wheels and a feed mechanism that ensures the material is fed into the blade at a controlled rate. This allows for precision cuts with minimal waste, ensuring that the final product meets the exact specifications required for further processing or assembly.

The Benefits of Horizontal Metal Cutting Band Saws

1. Enhanced Precision and Clean Cuts

One of the primary advantages of the horizontal metal cutting band saw is its ability to provide extremely precise cuts, particularly when dealing with dense or thick materials. The consistent pressure applied by the horizontal cutting blade helps produce smooth, accurate cuts, which is especially important in industries like aerospace, automotive, and precision engineering, where tolerances are tight.

In comparison to other cutting methods, horizontal metal cutting band saws produce less waste and offer cleaner edges, making them ideal for projects where material efficiency and high-quality finishes are essential. This makes it easier to prepare metals for further processing, welding, or assembly.

2. Improved Cutting Efficiency and Speed

Another reason for the growing popularity of the horizontal metal cutting band saw is its exceptional cutting speed. These saws are designed to work continuously and efficiently, making them a preferred choice for high-volume operations. With adjustable feed rates and cutting speeds, operators can tailor the saw to match the specific hardness and thickness of the material being cut, resulting in faster processing times and reduced downtime.

This improved cutting speed not only increases productivity but also reduces energy consumption. Since the horizontal saw cuts quickly and efficiently, it consumes less energy compared to slower, less efficient cutting methods. This makes horizontal metal cutting band saws a more sustainable option for businesses looking to reduce their carbon footprint.

3. Versatility for Different Materials

Horizontal metal cutting band saws are highly versatile machines capable of cutting through a wide variety of metals, including steel, aluminum, copper, and even tougher alloys. Many models come equipped with adjustable tension settings, allowing the machine to adapt to different types of materials, ensuring that cuts remain accurate regardless of the material being processed.

This adaptability makes the horizontal metal cutting band saw an invaluable tool for industries that work with multiple metals and require a single machine to handle different tasks. Whether cutting bars, rods, or plates, the band saw can be adjusted to meet the demands of various metalworking projects.

4. Increased Automation and Ease of Use

The advent of automated horizontal metal cutting band saws has revolutionized the metalworking industry. Many modern machines come equipped with digital controls, automatic feed systems, and programmable cutting paths. These automated features reduce the need for manual intervention, ensuring faster and more consistent results. With programmable settings, operators can set the saw to make specific cuts automatically, which eliminates errors and increases operational efficiency.

Additionally, the ergonomics of horizontal metal cutting band saws have been significantly improved. Many models feature user-friendly controls, easy-to-read displays, and adjustable settings that make it easier for operators to monitor and adjust the cutting process, even for complex tasks. This ease of use not only boosts productivity but also helps reduce the learning curve for new operators.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US