In the world of industrial manufacturing and woodworking, the band sawing machine has long been a crucial tool for cutting materials with precision and efficiency. As technology advances, the band sawing machine continues to evolve, incorporating innovative features that enhance performance and versatility. This article explores the latest advancements in the band sawing machine industry, highlights its key features, and provides insights into how these machines are transforming various sectors.

The band sawing machine has undergone significant changes since its inception. Originally designed as a simple cutting tool, the modern band sawing machine integrates sophisticated technology to meet the demands of contemporary manufacturing processes. These advancements aim to improve cutting accuracy, increase productivity, and extend the lifespan of the equipment.

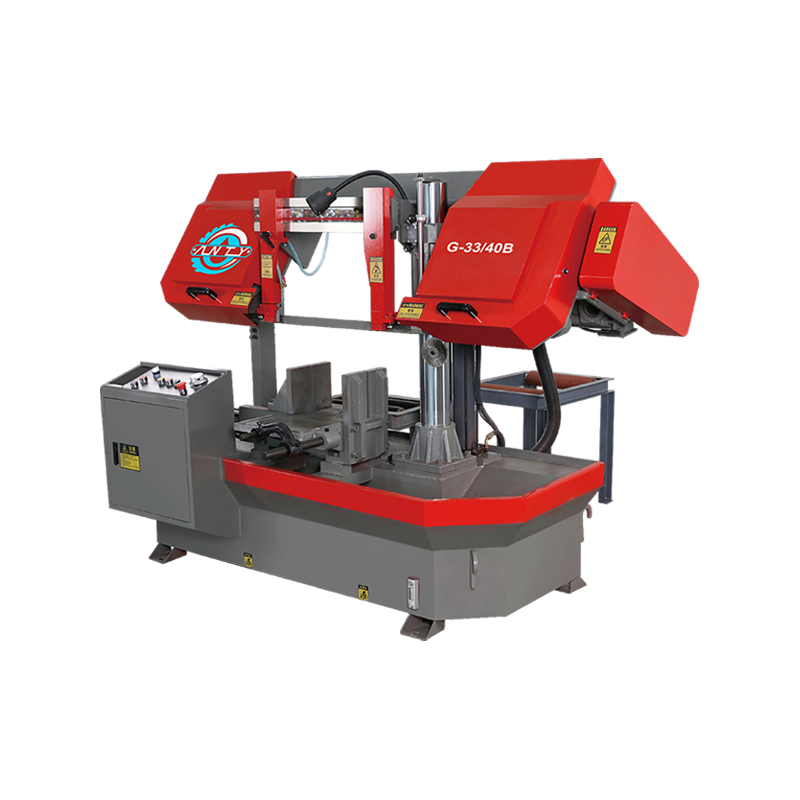

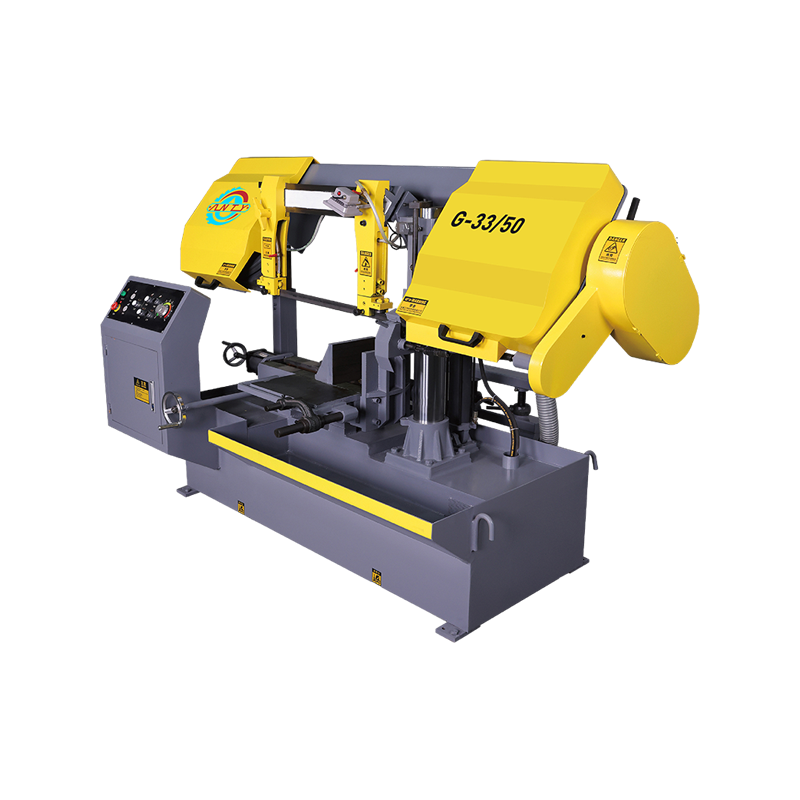

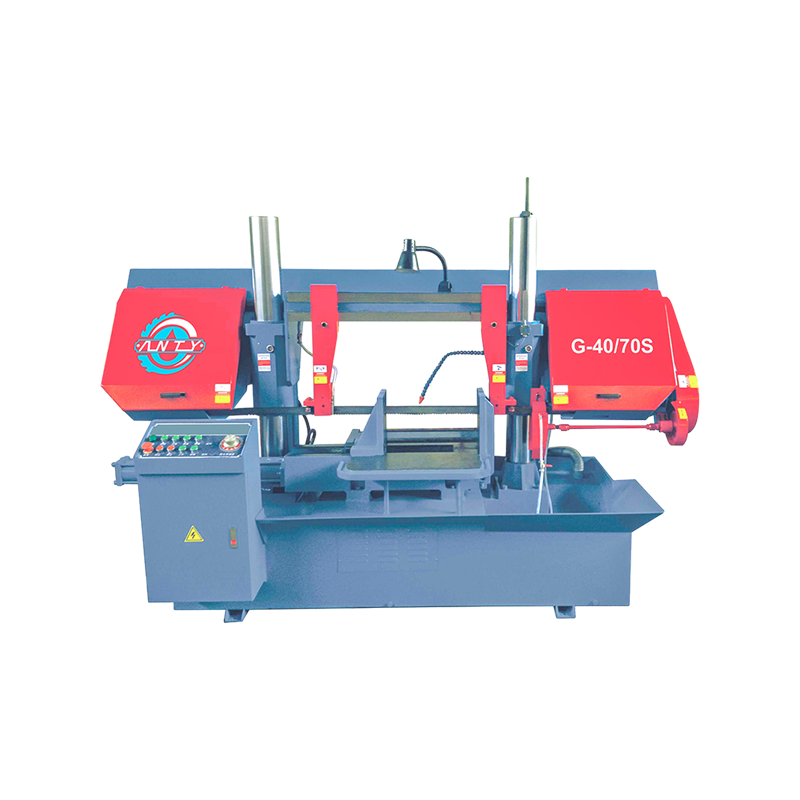

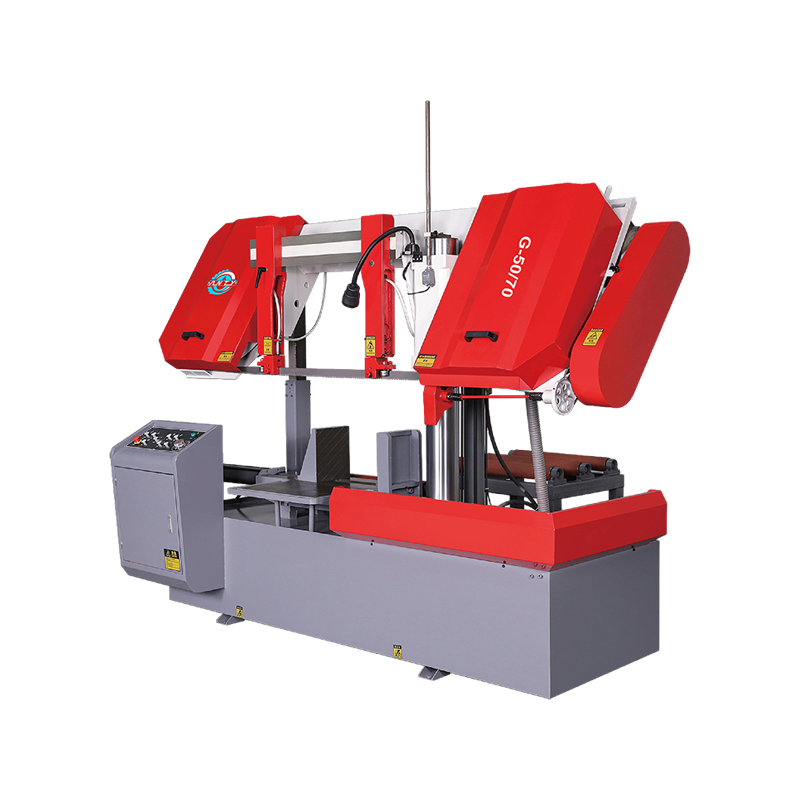

Band sawing machines are now equipped with advanced features such as digital controls, automatic feed systems, and precision-guided blades. These innovations are driving the future of the band sawing machine industry and offering new opportunities for businesses across different sectors.

Modern band sawing machines are equipped with digital controls that streamline the cutting process. These digital interfaces allow operators to set precise parameters for speed, feed rate, and cutting angles. The enhanced control systems in today’s band sawing machines ensure that every cut is accurate and consistent, significantly reducing the margin for error.

Automation is a major trend in the band sawing machine industry. Many of the latest models come with automatic feed systems that handle material loading, cutting, and unloading with minimal human intervention. This automation improves efficiency, reduces labor costs, and increases production rates.

Band sawing machines now feature precision-guided blades that enhance cutting accuracy. These blades are designed to maintain consistent tension and alignment, resulting in cleaner cuts and better overall performance. The advanced blade technology in modern band sawing machines ensures that even complex cuts are executed flawlessly.

The durability of a band sawing machine is crucial for long-term performance. Newer models are built with high-quality materials and advanced engineering to withstand rigorous use. Additionally, these machines often include features that make maintenance easier, such as accessible components and automated lubrication systems.

Modern band sawing machines are designed to handle a wide range of materials, from wood and metal to composites and plastics. This versatility allows businesses to use a single machine for various applications, making it a valuable asset in diverse manufacturing environments.

Safety is a top priority in the design of new band sawing machines. The latest models come equipped with advanced safety features, such as blade guards, emergency stop buttons, and safety sensors. These features help prevent accidents and ensure a safe working environment for operators.

As environmental concerns become more prominent, band sawing machines are being designed with energy efficiency in mind. New models are engineered to consume less power while delivering high performance. Energy-efficient band sawing machines not only reduce operational costs but also support sustainable manufacturing practices.

The user interfaces of modern band sawing machines are designed for ease of use. Intuitive touchscreens, simplified controls, and clear displays make it easier for operators to configure settings and monitor the cutting process. This user-friendly design reduces training time and improves overall efficiency.

Technological advancements have led to the development of cutting-edge technologies for band sawing machines. Features such as variable speed drives, programmable cut sequences, and high-speed sawing capabilities are now standard in many new models, allowing for more complex and efficient cutting processes.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US