In recent years, the timber industry has witnessed significant advancements in technology, with industrial portable band saw mills emerging as a game-changer in wood processing. These versatile machines not only enhance efficiency and productivity but also provide a sustainable solution for timber production. This article delves into the features, benefits, and applications of industrial portable band saw mills, highlighting their impact on the woodworking industry.

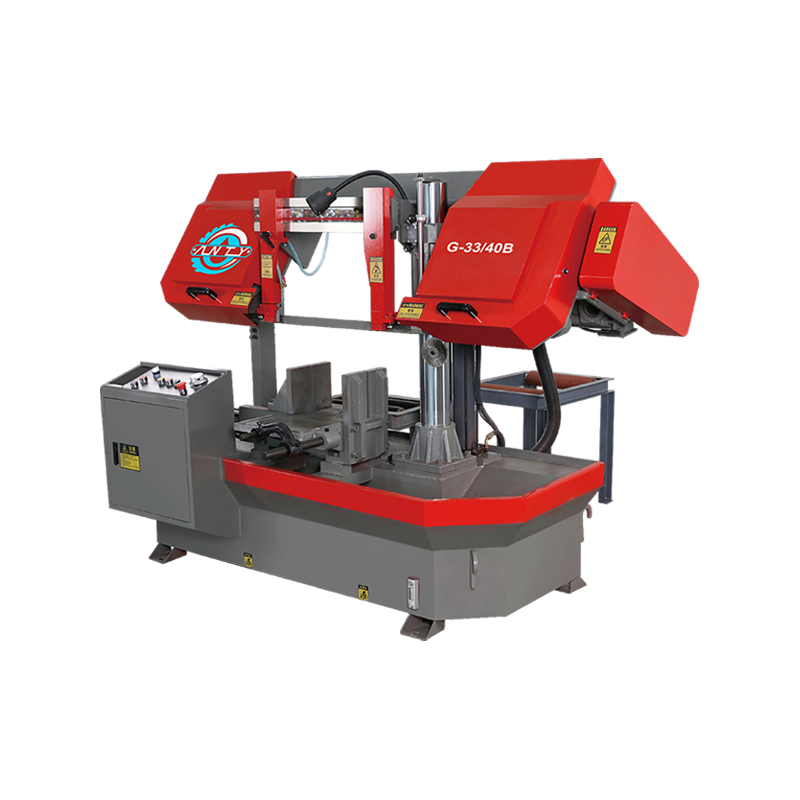

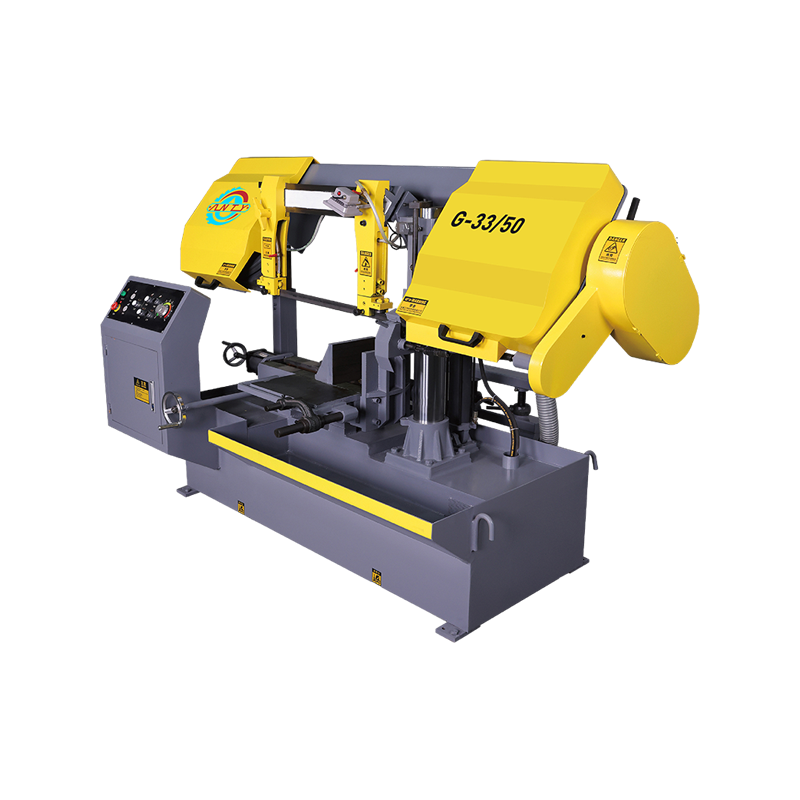

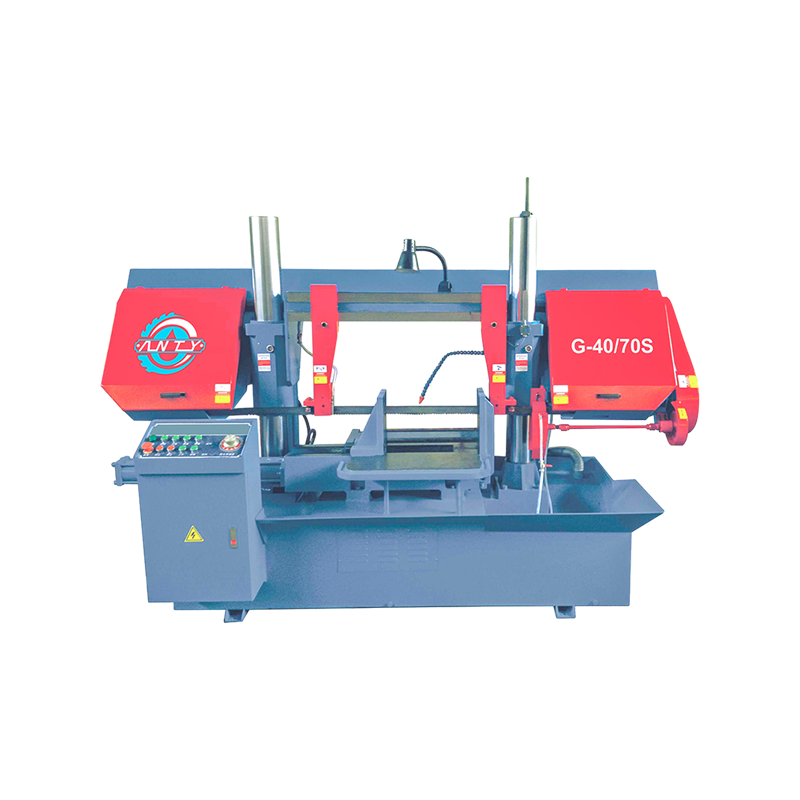

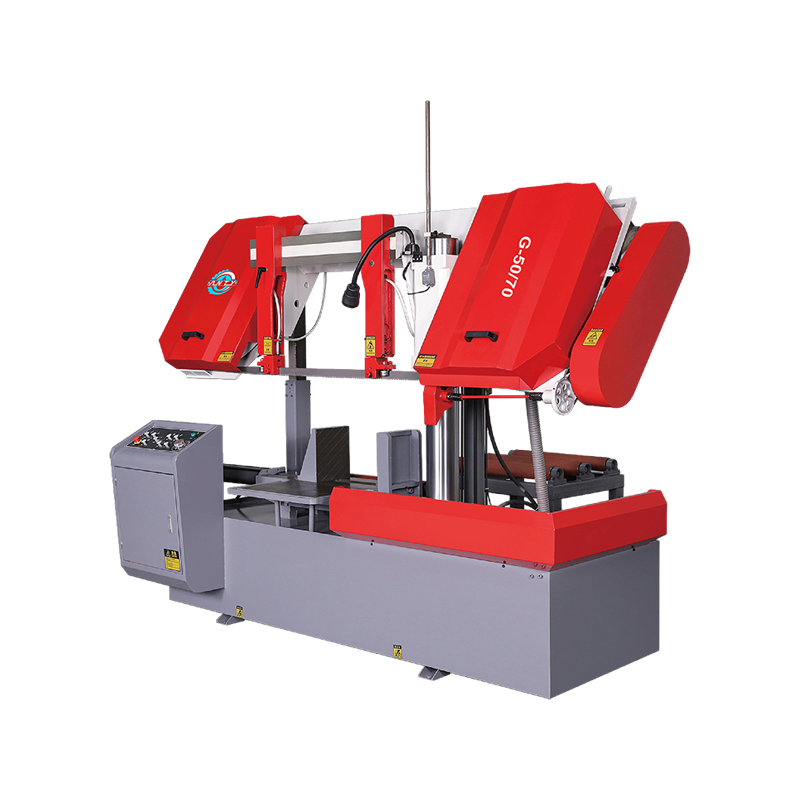

Understanding Industrial Portable Band Saw Mills

Industrial portable band saw mills are designed to cut logs into lumber efficiently and accurately. Unlike traditional sawmills, which are often fixed in one location, portable band saw mills can be transported to the site of the timber, allowing for on-site milling. This flexibility significantly reduces transportation costs and minimizes waste, making it an attractive option for sawmill operators and contractors.

The heart of a band saw mill is its continuous band blade, which is stretched between two wheels. The blade's design allows it to slice through logs with minimal kerf (the width of the cut), the yield of usable lumber. These mills are powered by various sources, including gas, diesel, and electric motors, offering operators a range of options based on their specific needs.

Key Features of Industrial Portable Band Saw Mills

Portability: The primary advantage of portable band saw mills is their ability to be moved to different locations. This is particularly beneficial for timber operations in remote areas or where access to traditional sawmill facilities is limited.

Adjustability: Many portable band saw mills come with adjustable cutting heights and widths, allowing operators to customize their cuts based on the size and type of logs they are working with. This adaptability enhances efficiency and precision.

User-Friendly Controls: Modern industrial portable band saw mills are equipped with intuitive controls and features such as automatic feed systems, which allow for smoother operation and reduced labor costs. Operators can easily adjust settings to optimize their milling process.

Durability and Robustness: Designed for heavy-duty use, these mills are built to withstand the rigors of outdoor operations. They are often constructed with high-quality materials that can endure harsh weather conditions and demanding workloads.

Efficient Waste Management: With a smaller kerf compared to circular saws, band saw mills produce less waste, which is an essential factor in sustainable timber production. Operators can maximize the amount of usable wood from each log, reducing the overall environmental impact.

Benefits of Using Portable Band Saw Mills

Cost-Effectiveness: The portability of these mills significantly reduces transportation costs. Timber can be milled on-site, eliminating the need to transport heavy logs to a fixed location. This not only saves money but also decreases the carbon footprint associated with hauling timber.

Time Savings: Industrial portable band saw mills streamline the milling process. Operators can quickly set up the mill at the job site and begin cutting, resulting in faster turnaround times for lumber production. This efficiency is particularly crucial for contractors who need to meet tight deadlines.

Versatility: These mills can handle a variety of wood species, from softwoods to hardwoods, making them suitable for various applications, including furniture production, construction, and specialty wood products.

Increased Yield: The precision of band saw milling maximizes the amount of usable lumber obtained from each log. Operators can produce high-quality boards with minimal defects, which is essential for meeting market demands.

Sustainability: By reducing waste and allowing for on-site processing, industrial portable band saw mills contribute to more sustainable forestry practices. They promote responsible timber harvesting and can help minimize the impact on local ecosystems.

Applications of Industrial Portable Band Saw Mills

Custom Woodworking: Craftsmen and custom woodworkers benefit from the flexibility of portable band saw mills. They can source local timber and create bespoke pieces tailored to their clients’ specifications, enhancing creativity and craftsmanship.

Construction Projects: Contractors often use portable band saw mills for on-site milling of framing lumber and other materials. This approach allows for quick adjustments and adaptations to project specifications, improving overall efficiency.

Timber Harvesting: Forestry operations utilize these mills for processing logs directly in the woods. This practice reduces transportation costs and allows for immediate milling, ensuring that timber is processed while it is still fresh.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US