What Maintenance Steps Keep Metal Cutting Band Sawing Machine Stable?

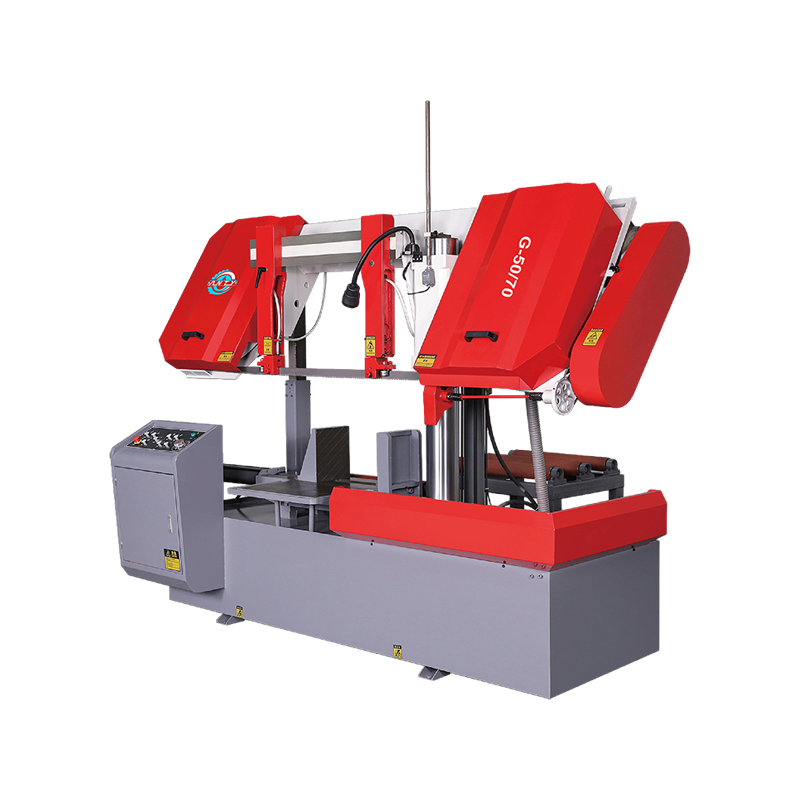

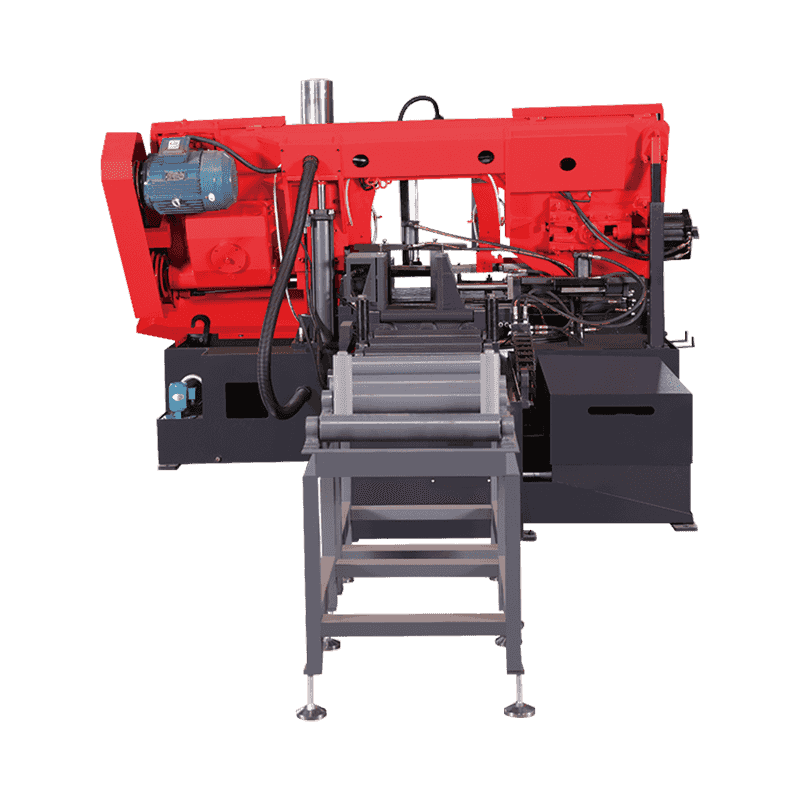

Workshops that operate both a CNC full automatic High speed circular sawing machine and a metal cutting band sawing machine often notice that stability in long-term band saw operation depends heavily on maintenance habits rather than equipment age alone. Many technicians focus only on blade replacement, yet a band sawing machine requires broader and more consistent care to maintain steady performance. Understanding these maintenance areas helps users prevent unexpected issues and keep the machine running smoothly during daily cutting tasks. Blade Condition Directly Affects Cutting Stability A worn, chipped, or improperly tensioned blade can cause vibration, uneven cutting surfaces, or deviations in length. Technicians should check the blade teeth regularly, especially when the machine handles harder materials.Correct blade tension helps keep the blade on track and reduces sideways movement. Some operators adjust tension only when noticing noise or surface inconsistencies, but checking tension before each shift provides a clearer baseline. If the workshop uses different blade widths for different tasks, confirming that each blade matches the machine’s tension range helps avoid unnecessary strain on the wheel system. Lubrication Helps Maintain Smooth Movement Lubrication is essential for the saw blade guide system, moving components, and bearings. Without regular lubrication, friction increases, which can create unstable cutting and unnecessary machine wear. Applying appropriate lubricant at recommended intervals helps keep the blade moving consistently through the guide arms.Coolant is another area often overlooked. A steady coolant flow keeps the blade temperature under control and supports more uniform cutting. When coolant passages become partially blocked, the blade may heat unevenly, affecting straightness. Operators should check coolant levels, filter screens, and nozzle direction to ensure a smooth, uninterrupted flow. Regular Alignment Checks Support Accurate Cutting Paths Misalignment can develop slowly as the machine experiences daily vibration and heavy workloads. When the band wheels, guide arms, or worktable drift out of alignment, the blade may wander during cutting. This does not always show immediate symptoms, but over time it affects cut accuracy and results in more material waste.Periodic checks of wheel alignment, guide arm parallelism, and vise positioning help technicians identify early signs of drift. Correcting small alignment deviations early prevents larger performance issues. For workshops using both circular sawing machines and band saws, maintaining alignment ensures that both machines produce consistent workpiece lengths, allowing them to complement each other without introducing dimensional differences. Cleaning Routines Reduce Build-Up That Affects Stability Metal chips and dust gradually accumulate around the blade path, drive wheels, and coolant system. Over time, these small particles can interfere with guide movement or cause unnecessary friction. A simple cleaning routine at the end of each shift can help prevent build-up in the machine’s moving areas.Removing chips from the blade gullets also matters. When gullets fill with debris, the blade may not clear chips efficiently, which can cause rough cutting or chatter. A clean machine is not only easier to inspect but also maintains more predictable cutting behavior. Checking the Drive System Helps Maintain Steady Power Transmission The drive belt, motor, and transmission components influence how smoothly power is delivered to the blade. If a belt starts slipping or develops cracks, the blade speed may fluctuate. These small fluctuations can affect cut quality, especially during long work cycles.Routine inspections of belt tension, motor temperature, and pulleys help technicians identify developing issues early. Replacing worn belts or tightening loose connections supports a more consistent cutting motion and reduces the chance of sudden performance drops during production. Hydraulic System Maintenance Supports Stable Clamping For band saws equipped with hydraulic tensioning or clamping systems, hydraulic health is essential. Low fluid levels, aging fluid, or worn seals can reduce clamping force. When the workpiece is not held firmly, vibration increases and the blade may drift during cutting.Technicians should monitor fluid condition and ensure that hoses and seals remain intact. Stable clamping is especially important when cutting heavy or solid stock, where any movement affects both accuracy and safety. Guide Arm and Vise Adjustments Influence Blade Tracking Guide arms keep the blade stable as it enters and exits the workpiece. If the guides sit too far from the material, the blade may be allowed to flex. If set too close, friction increases. Finding the correct spacing is essential for smooth cutting.The vise should also close uniformly and apply even pressure. Uneven clamping forces can tilt the workpiece, increasing the chance of blade wander. A simple test cut can help verify that the machine holds material correctly.

english

english Русский

Русский Español

Español Русский

Русский

READ MORE

READ MORE