In the realm of manufacturing, precision and efficiency are critical factors that influence production quality and operational effectiveness. The evolution of machinery technology has significantly impacted various industries, and among the crucial advancements is the development of modern band sawing machines. These machines have revolutionized the cutting processes in manufacturing, offering enhanced accuracy, speed, and versatility. This article delves into the latest advancements in band sawing machines, exploring their benefits, applications, and the role they play in modern manufacturing.

The band sawing machine has a long history, dating back to its invention in the early 19th century. Originally designed for basic cutting tasks, early models were limited in terms of speed, accuracy, and material compatibility. However, the modern band sawing machine has undergone significant advancements, incorporating cutting-edge technology to meet the demands of contemporary manufacturing.

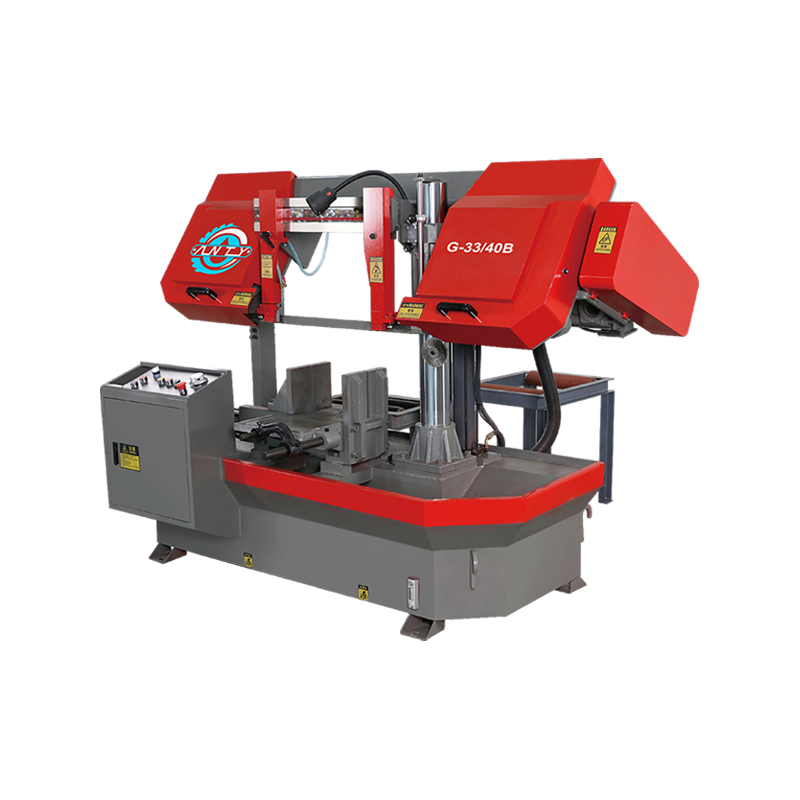

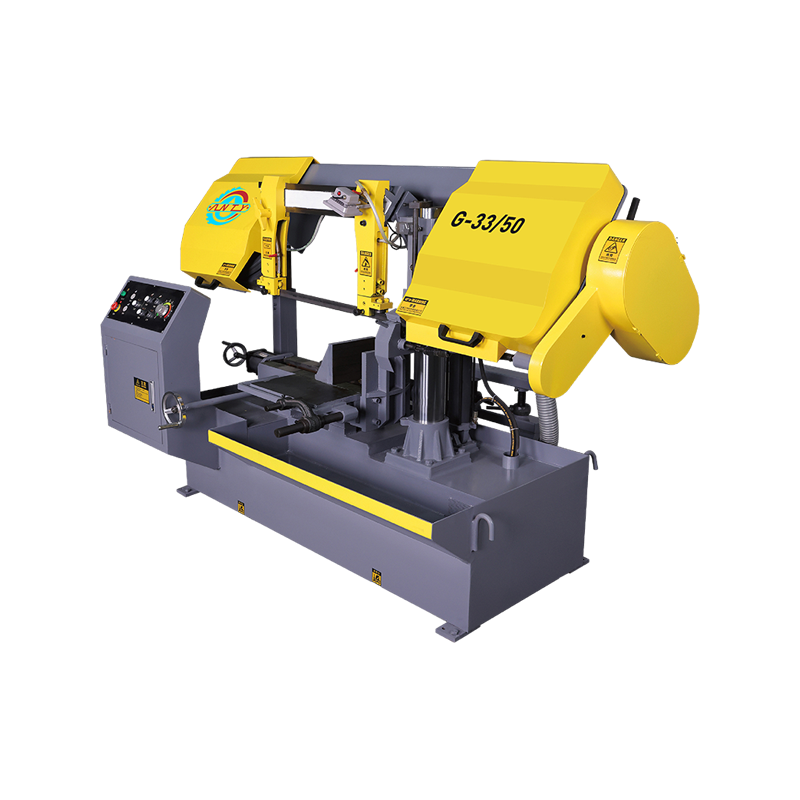

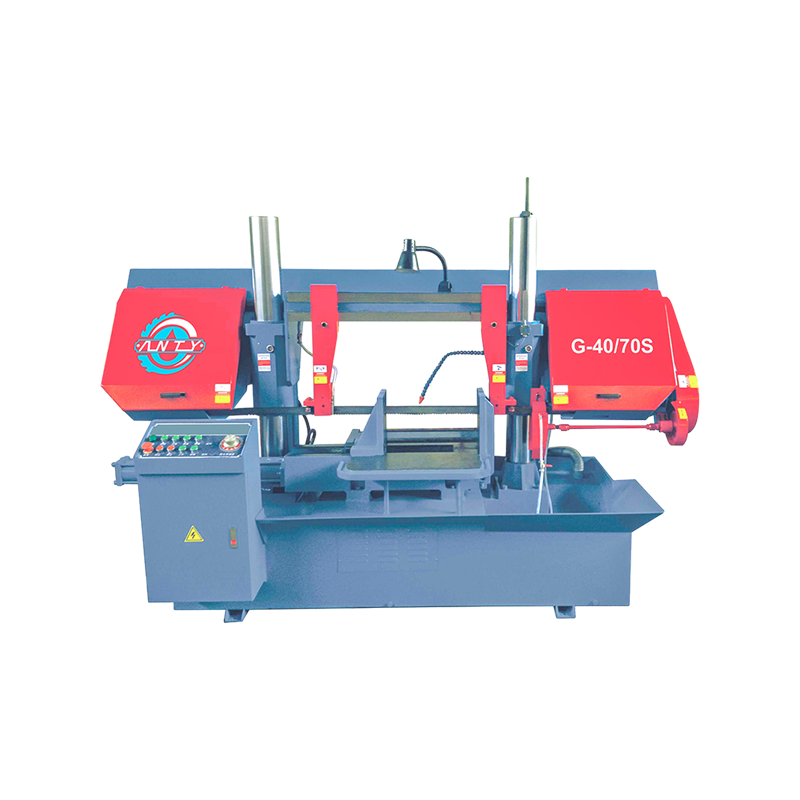

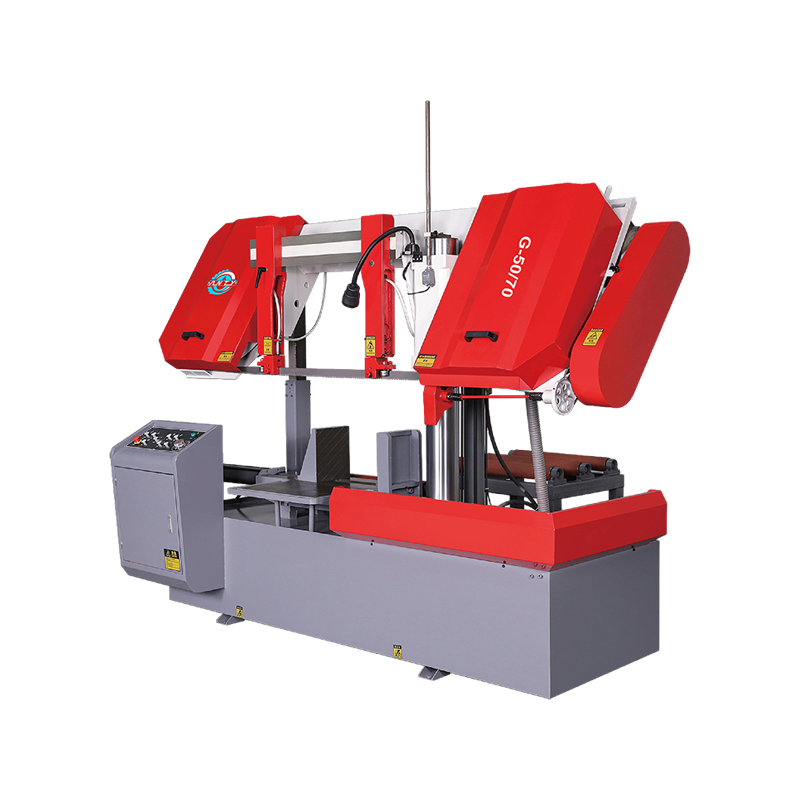

Today’s band sawing machines are equipped with advanced features that enhance their functionality and performance. Innovations include computer numerical control (CNC) systems, automated feed mechanisms, and sophisticated blade technology. These advancements allow for precise and efficient cutting of a wide range of materials, from metals and plastics to wood and composites. The integration of digital controls and automation has transformed the band sawing machine into a highly versatile and reliable tool in the manufacturing process.

One of the primary benefits of modern band sawing machines is their precision. Equipped with advanced CNC technology, these machines can achieve high levels of accuracy in cutting, ensuring that components meet stringent specifications. The ability to make precise cuts reduces material waste and improves overall product quality, making band sawing machines an essential tool in industries where precision is paramount.

Speed and efficiency are also notable advantages of modern band sawing machines. With automated feed systems and high-speed cutting capabilities, these machines can handle large volumes of material quickly and efficiently. This increased speed not only boosts productivity but also reduces labor costs by minimizing manual intervention. The efficiency of band sawing machines contributes to faster turnaround times and improved operational workflows in manufacturing facilities.

The versatility of band sawing machines is another significant benefit. Modern machines are designed to cut a wide range of materials, including metals, plastics, wood, and composites. This adaptability makes them suitable for various applications across different industries, from automotive and aerospace to construction and furniture manufacturing. The ability to switch between different materials and cutting profiles with ease enhances the machine’s utility and makes it a valuable asset in diverse manufacturing environments.

Band sawing machines are used in a variety of manufacturing applications, each leveraging the machine’s precision, speed, and versatility. In the metalworking industry, band sawing machines are employed to cut metal bars, plates, and tubes into specific sizes and shapes. The machine’s ability to handle different metal types, including steel, aluminum, and stainless steel, makes it a crucial tool in fabricating components for machinery, automotive parts, and structural elements.

In the woodworking industry, band sawing machines are used to cut large timbers, plywood, and veneer sheets. The machine’s precision allows for the creation of intricate wood designs and components used in furniture, cabinetry, and architectural elements. Additionally, band sawing machines can be used to resaw logs into planks or panels, the yield from raw materials and reducing waste.

The plastics and composites industry also benefits from the use of band sawing machines. These machines are capable of cutting through various plastic materials, including acrylics, polycarbonates, and composite panels. The ability to achieve clean and accurate cuts is essential for producing components used in consumer goods, electronic enclosures, and structural applications.

The future of band sawing machines is likely to be shaped by ongoing innovations in technology and manufacturing processes. One of the key areas of development is the integration of advanced automation and robotics. Automated loading and unloading systems, coupled with robotic arms, are expected to enhance the efficiency and precision of band sawing machines, further reducing labor costs and improving overall productivity.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US