In the ever-evolving world of manufacturing and metalworking, the horizontal metal cutting band saw has emerged as a cornerstone technology for precision and efficiency. Over the past few years, significant advancements in this essential tool have transformed its capabilities, offering new solutions for a wide range of industrial applications. This article delves into the latest innovations in the horizontal metal cutting band saw, exploring how these developments are shaping the future of metal cutting and what lies ahead for this vital piece of machinery.

The horizontal metal cutting band saw has a long history as a reliable tool for cutting through metal. Initially, these saws were relatively simple machines, but recent innovations have redefined their functionality and effectiveness. Modern horizontal metal cutting band saws are now equipped with advanced features that enhance their performance and adaptability, making them indispensable in today's manufacturing environments.

Recent advancements in the horizontal metal cutting band saw have introduced a range of new technologies that improve efficiency, precision, and user experience. These technologies are driving significant changes in how metal cutting is approached across various industries.

One of the impactful innovations in the horizontal metal cutting band saw is the development of advanced control systems. Modern models feature sophisticated digital control panels that allow operators to program cutting parameters with high precision. These systems often include touchscreen interfaces, real-time performance monitoring, and automated adjustment capabilities, which streamline the cutting process and reduce the likelihood of errors.

Blade technology has seen remarkable advancements in the horizontal metal cutting band saw. New blades are designed with advanced materials and cutting-edge manufacturing techniques, such as high-speed steel and carbide-tipped blades, which offer durability and performance. These blades extend the life of the saw, provide smoother cuts, and are capable of handling a wider range of metal types and thicknesses.

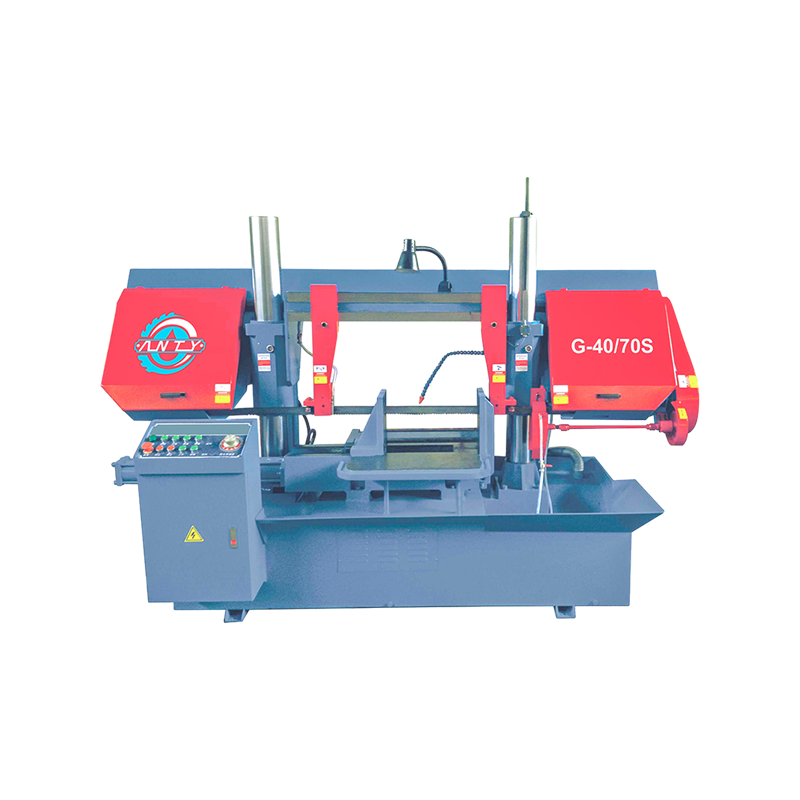

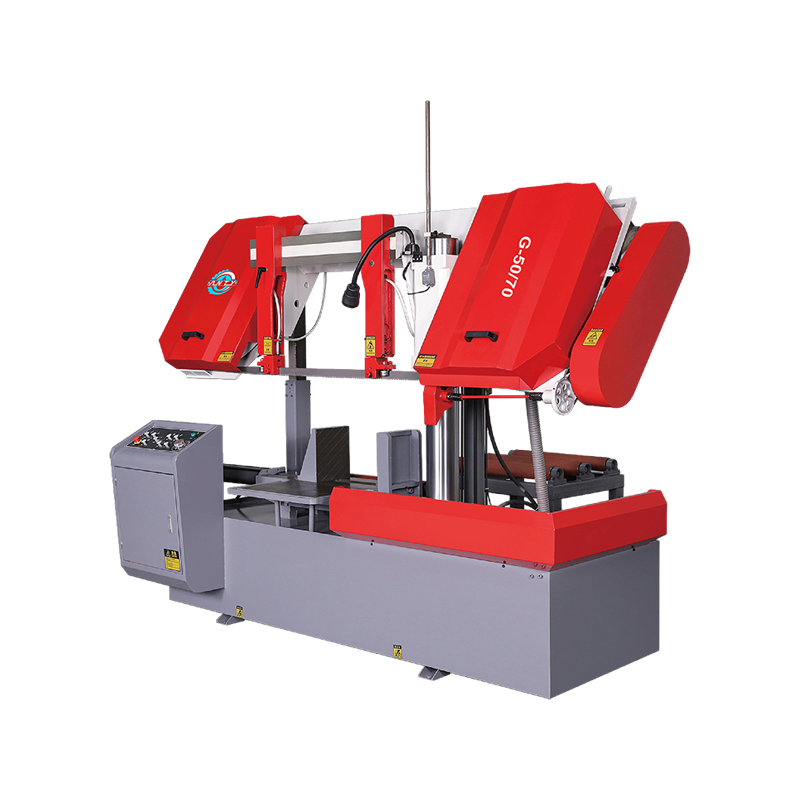

Automation has become a key trend in the development of the horizontal metal cutting band saw. Recent models are equipped with automated material handling systems, such as automatic feed mechanisms, programmable indexing, and robotic loading and unloading capabilities. These features increase productivity by reducing manual labor and enabling continuous operation without the need for constant supervision.

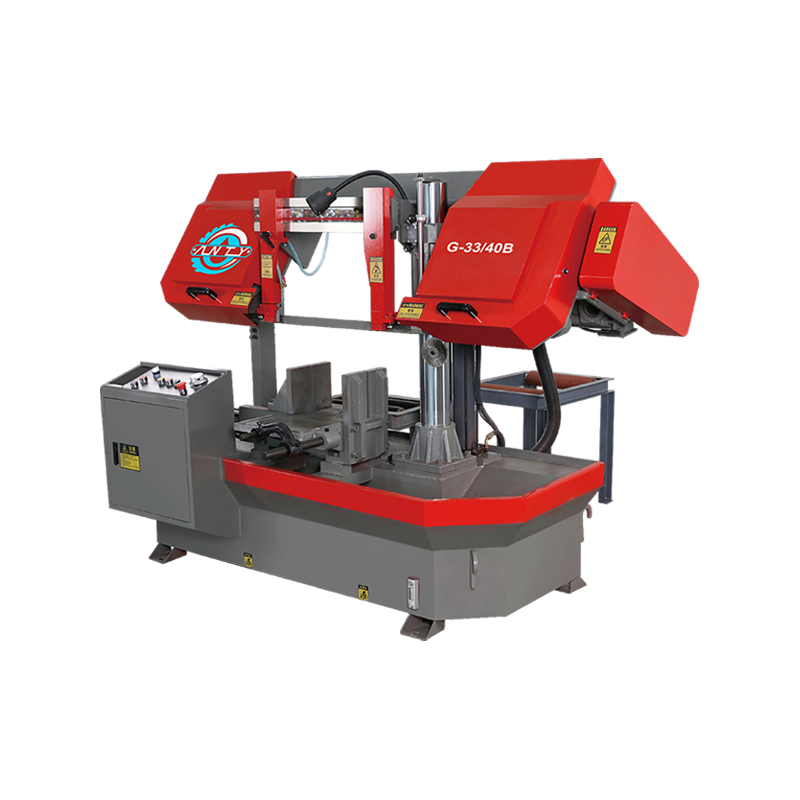

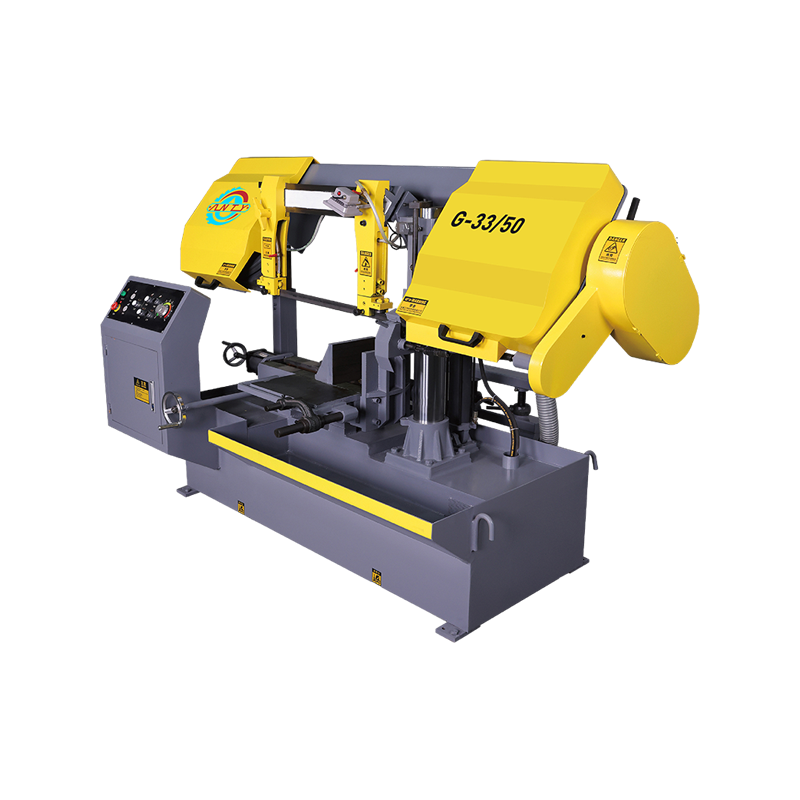

Modern horizontal metal cutting band saws offer increased cutting capacities and greater versatility compared to their predecessors. Advances in hydraulic systems and structural design have allowed these machines to handle larger workpieces and perform complex cuts with ease. Additionally, adjustable guides and multi-angle cutting capabilities enable operators to perform a variety of tasks with a single machine.

The innovations in the horizontal metal cutting band saw are having a profound impact on the manufacturing and metalworking industries. These machines are not only enhancing productivity but also setting new standards for quality and efficiency.

The advanced features of the latest horizontal metal cutting band saws to significant improvements in production efficiency. Automated systems and precise control mechanisms enable faster setup times, reduced downtime, and more consistent cutting results. This efficiency translates into higher production rates and reduced operational costs for manufacturers.

The precision and reliability of modern horizontal metal cutting band saws contribute to higher product quality. Improved blade technology and advanced control systems ensure that cuts are accurate and clean, which is essential for producing high-quality metal components. This focus on quality helps manufacturers meet stringent industry standards and customer expectations.

Investing in the latest horizontal metal cutting band saw technology can to significant cost savings. The increased efficiency and reduced maintenance requirements of these machines offer a strong return on investment. By lowering operational costs and extending the life of the saw, manufacturers can achieve better financial outcomes and improve their bottom line.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US