In the realm of lumber production and woodworking, the industrial portable band saw mill has emerged as a game-changer. Over the past few years, advancements in technology have propelled these machines from basic, mobile cutting tools to sophisticated instruments that redefine efficiency and precision in timber processing. This article explores the latest developments in industrial portable band saw mills, examining how they are transforming the industry and what the future holds.

Historically, sawmills were large, stationary structures, often requiring significant infrastructure and considerable space. The introduction of the industrial portable band saw mill marked a significant shift, offering a more flexible, efficient, and cost-effective solution for timber processing. These mills have evolved from simple machines into complex systems featuring cutting-edge technology and advanced engineering.

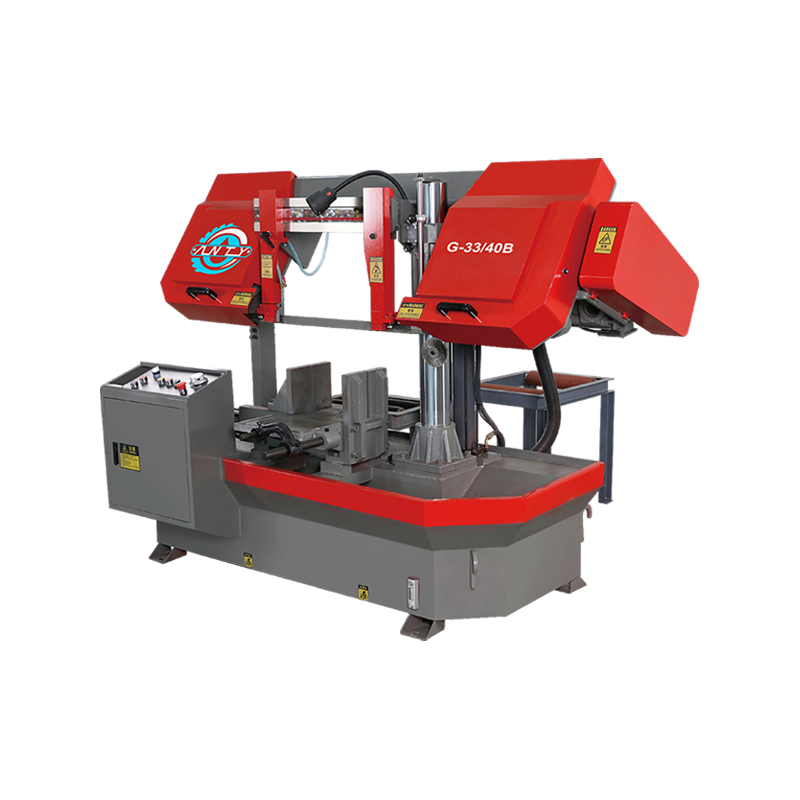

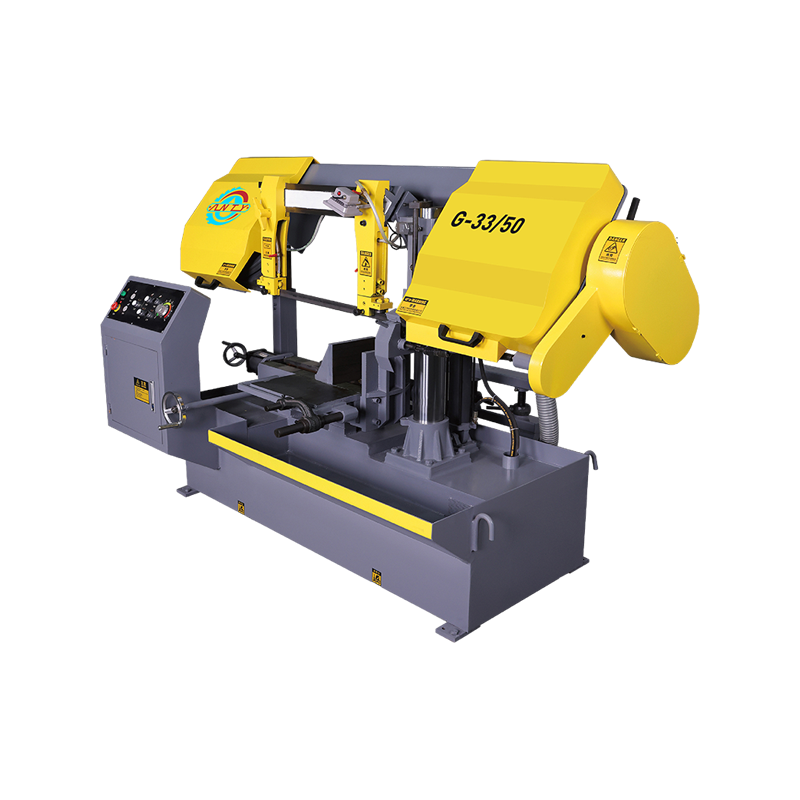

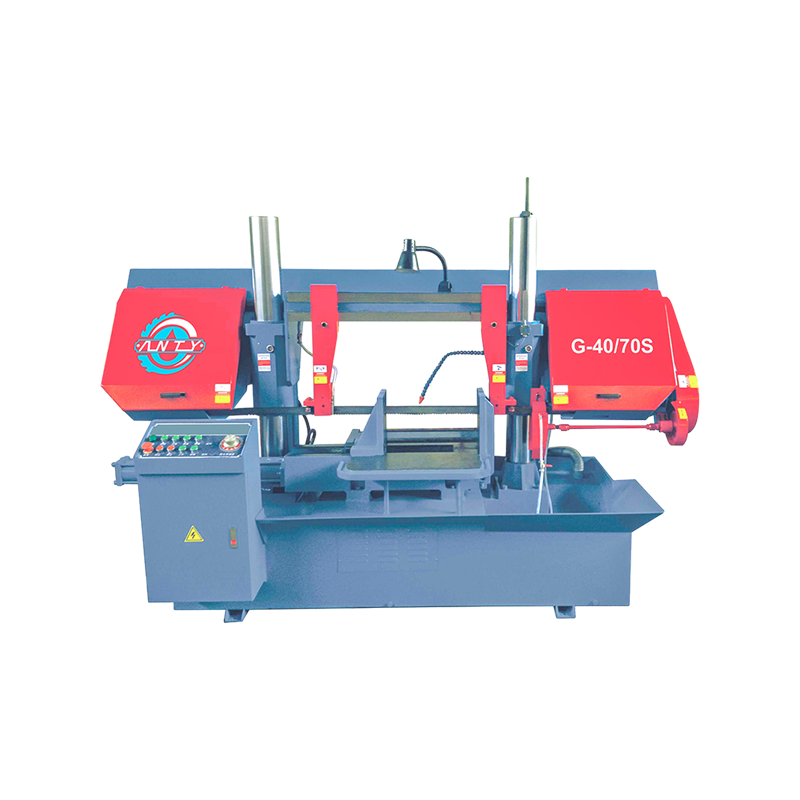

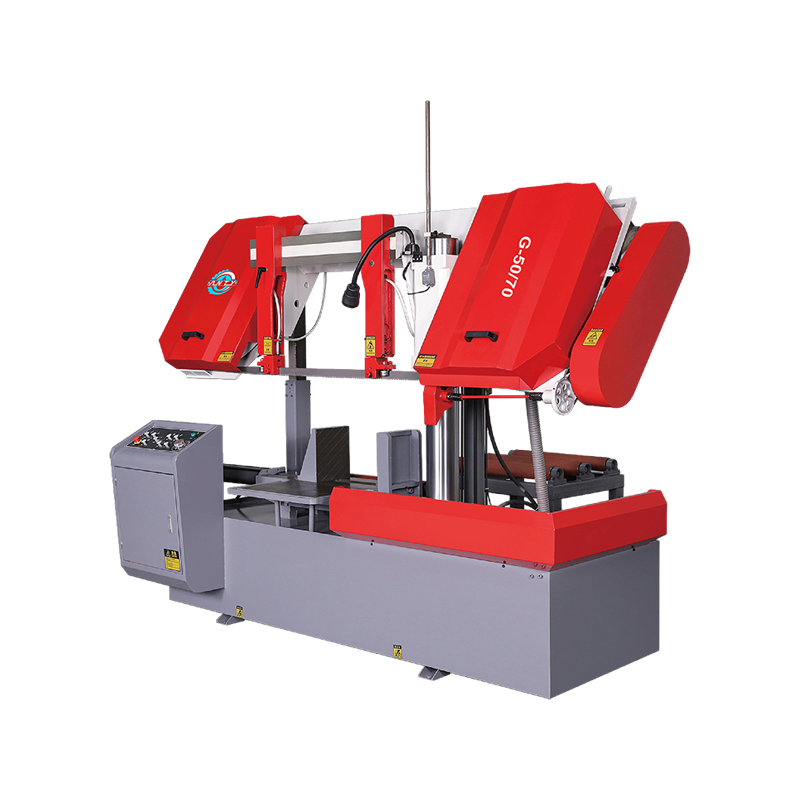

Recent innovations have dramatically enhanced the capabilities of the industrial portable band saw mill. Modern models are equipped with a range of features designed to improve performance, efficiency, and user experience.

One of the notable advancements in the industrial portable band saw mill is the improvement in cutting precision. State-of-the-art models now feature digital readouts, automated measurements, and advanced blade tracking systems. These technologies ensure that every cut is accurate and consistent, which is crucial for producing high-quality lumber.

The portability of these mills has always been one of their greatest advantages. However, recent developments have made the industrial portable band saw mill even more versatile. New designs feature modular components that can be easily assembled and disassembled, allowing operators to transport the mill to different job sites with minimal effort. Additionally, these mills now come with adjustable legs and leveling systems, enabling them to operate on uneven terrain.

Automation has revolutionized many industries, and the industrial portable band saw mill is no exception. Modern mills are now equipped with automated log handling systems, including conveyors, log turners, and hydraulic lifts. These features reduce the need for manual labor, increase processing speed, and enhance overall productivity.

Recent models of the industrial portable band saw mill come with more powerful engines that provide higher cutting speeds and greater efficiency. These engines are designed to handle a variety of wood types and sizes, from small, delicate pieces to large, heavy logs. Enhanced fuel efficiency and lower emissions are also key features of these new engines, aligning with environmental sustainability goals.

The advancements in the industrial portable band saw mill have had a profound impact on the timber industry. These machines offer numerous benefits that contribute to the efficiency and profitability of lumber production.

The increased efficiency of the industrial portable band saw mill translates into significant cost savings for timber producers. By automating many aspects of the cutting process and reducing the need for manual labor, these mills lower operational costs. Additionally, the precision of modern band saw mills reduces waste and maximizes the yield from each log, further driving down costs.

With the automation features and powerful engines of the latest industrial portable band saw mills, production capacity has increased dramatically. Timber producers can process larger quantities of wood in less time, meeting higher demands and expanding their market opportunities.

The advanced technology of the industrial portable band saw mill ensures that each cut is precise and consistent. This improved quality results in lumber products, which are essential for both commercial and residential woodworking projects. The ability to produce high-quality wood efficiently has opened up new avenues for businesses in the timber industry.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US