In the rapidly evolving world of timber processing, portable industrial band saw mills have become indispensable tools for businesses looking to boost operational efficiency and reduce costs. These innovative machines offer a range of advantages, from flexibility and mobility to precision cutting and cost savings, making them a crucial asset for the modern lumber industry.

The Rise of Portable Industrial Band Saw Mills

Traditional sawmills have long been the go-to solution for large-scale timber processing. However, as industries move toward more sustainable and cost-effective practices, portable band saw mills have grown in popularity. These compact yet powerful machines bring the mill to the job site, eliminating the need for transporting large volumes of timber to stationary mills. This capability offers a significant advantage, especially for businesses working in remote areas or for those looking to cut costs associated with hauling logs.

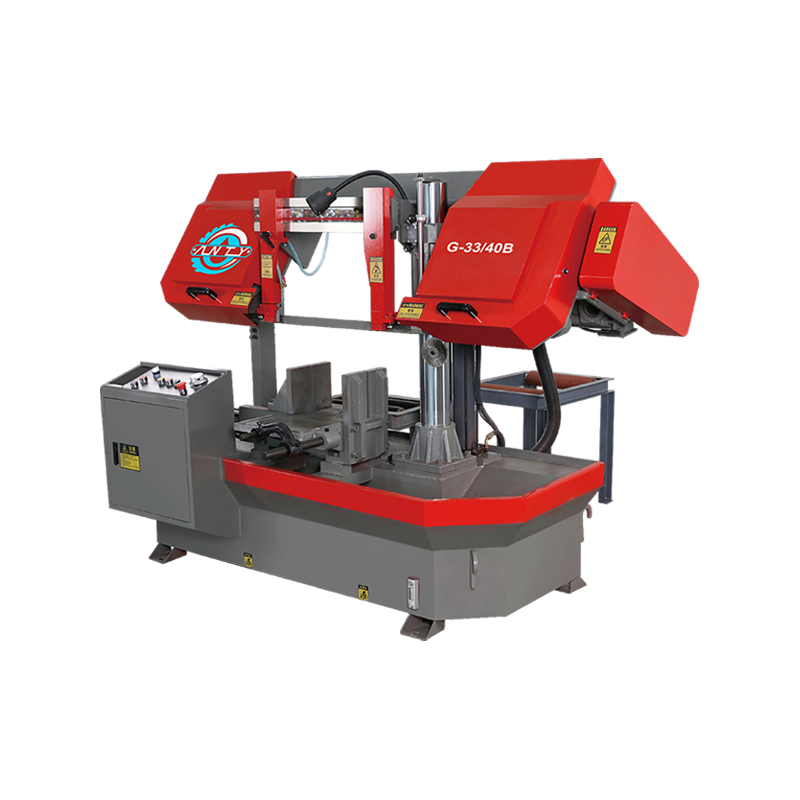

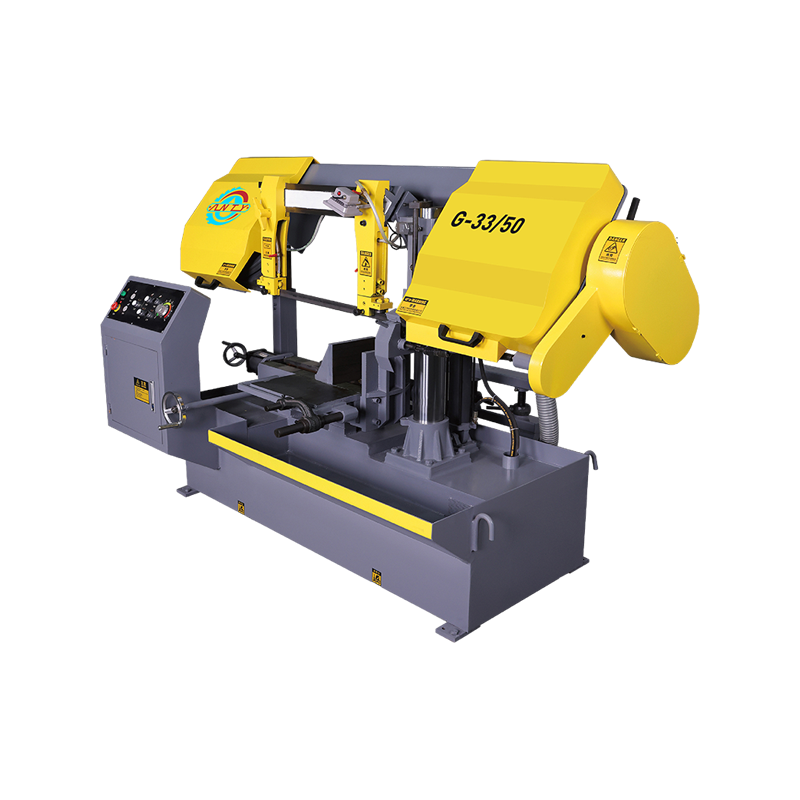

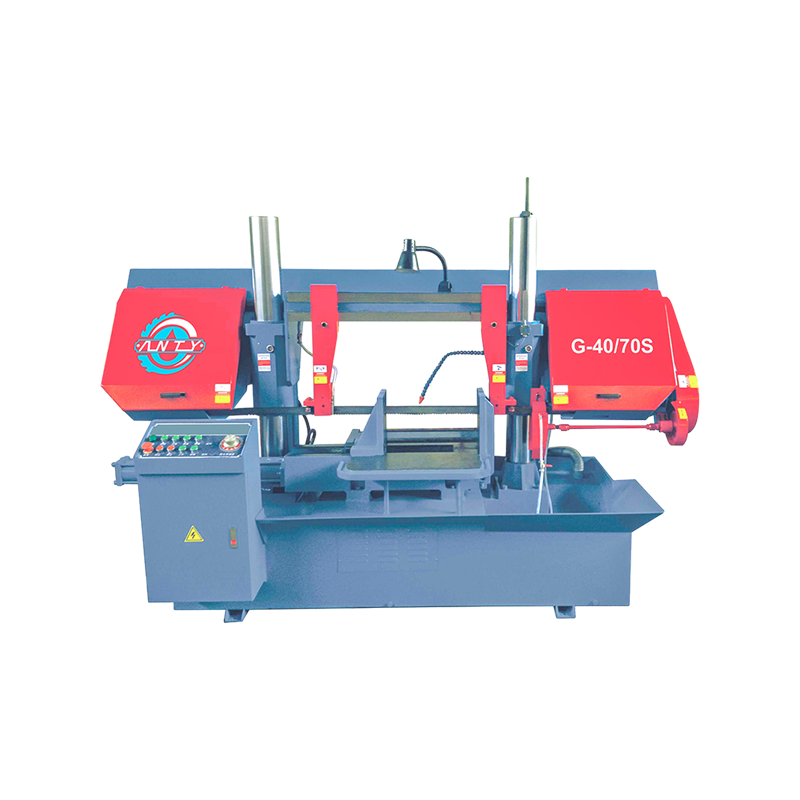

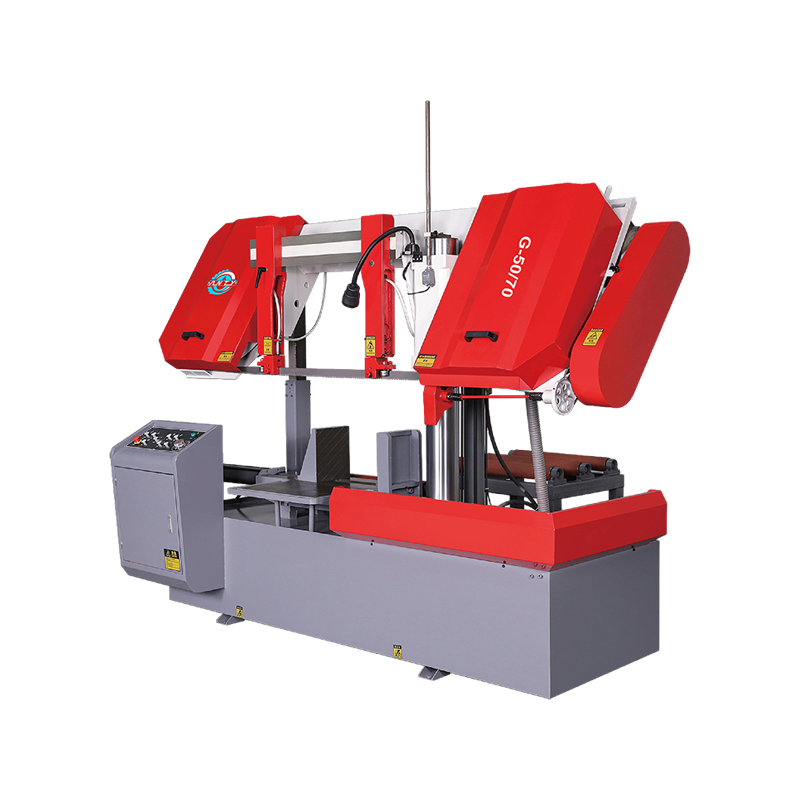

Portable industrial band saw mills are designed to handle a variety of cutting tasks, from cutting logs into lumber to producing custom cuts for specialized projects. They typically feature a band saw blade that moves in a continuous loop, which allows for more precise and efficient cuts than traditional circular saws. Additionally, portable band saw mills are lightweight and easy to transport, which makes them ideal for businesses that need to process timber quickly and on-site.

Key Benefits of Portable Industrial Band Saw Mills

Increased Mobility

One of the standout features of portable industrial band saw mills is their mobility. These machines can be easily transported to remote job sites, ensuring that businesses can process timber where it's sourced, without having to rely on long-distance transportation. Whether it's a large-scale construction project, a forestry operation, or even a smaller woodworking business, portable mills allow for on-the-spot processing, reducing the need for expensive trucking and transport.

Precision and Efficiency

When it comes to timber processing, precision is critical. Portable industrial band saw mills are designed to provide consistent, accurate cuts, ensuring that the final product meets the required specifications. These machines can be equipped with various features such as adjustable blades, cutting guides, and automated feed systems, all of which help to maximize efficiency and minimize material waste. This precision is essential for producing high-quality lumber and custom cuts for unique projects, whether in construction, furniture-making, or other wood-based industries.

Cost Savings

For many businesses, cost-effectiveness is at the top of the priority list. Portable industrial band saw mills offer significant cost savings over traditional stationary mills. , they eliminate the need to transport logs to centralized facilities, saving on both fuel and labor costs. Second, they reduce the amount of waste material generated during the cutting process, as they can be calibrated to make precise cuts with minimal wastage. Third, portable mills often require less maintenance and lower upfront investment compared to their stationary counterparts, making them an attractive option for small and medium-sized businesses.

Flexibility and Versatility

Portable band saw mills are incredibly versatile. They can process logs of varying sizes and types, from softwoods to hardwoods, and can be used for a variety of applications, including cutting lumber for construction, flooring, furniture, and even specialty wood products. Many models come with adjustable cutting heights and blade options, allowing for a broad range of custom cuts to suit different projects. This flexibility enables businesses to diversify their services and meet the unique demands of customers.

Sustainability

Sustainability has become a key concern for industries worldwide, and the timber sector is no exception. Portable industrial band saw mills contribute to environmentally friendly practices by minimizing the environmental impact of timber processing. Since these mills are often used directly at the logging site, they eliminate the need for transporting timber over long distances, which reduces fuel consumption and greenhouse gas emissions. Furthermore, the precision cuts produced by band saw mills result in less wood waste, allowing businesses to maximize the use of each log.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US