In today’s manufacturing and production environments, the demand for precise, reliable cutting equipment is higher than ever. Whether cutting metal, wood, plastic, or other materials, businesses rely on the accuracy and efficiency provided by bandsaws. Horizontal and vertical bandsaws have become essential tools in various industries due to their unmatched precision and versatility. These machines are pivotal in shaping products, components, and raw materials, making them indispensable in sectors such as metalworking, woodworking, construction, and even research and development.

The Basics of Horizontal and Vertical Bandsaws

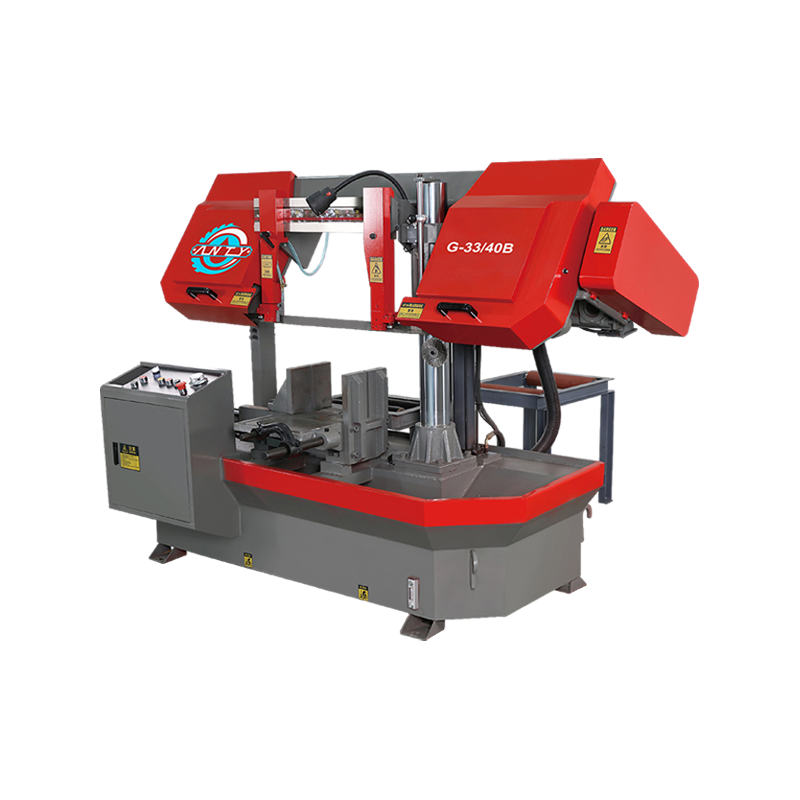

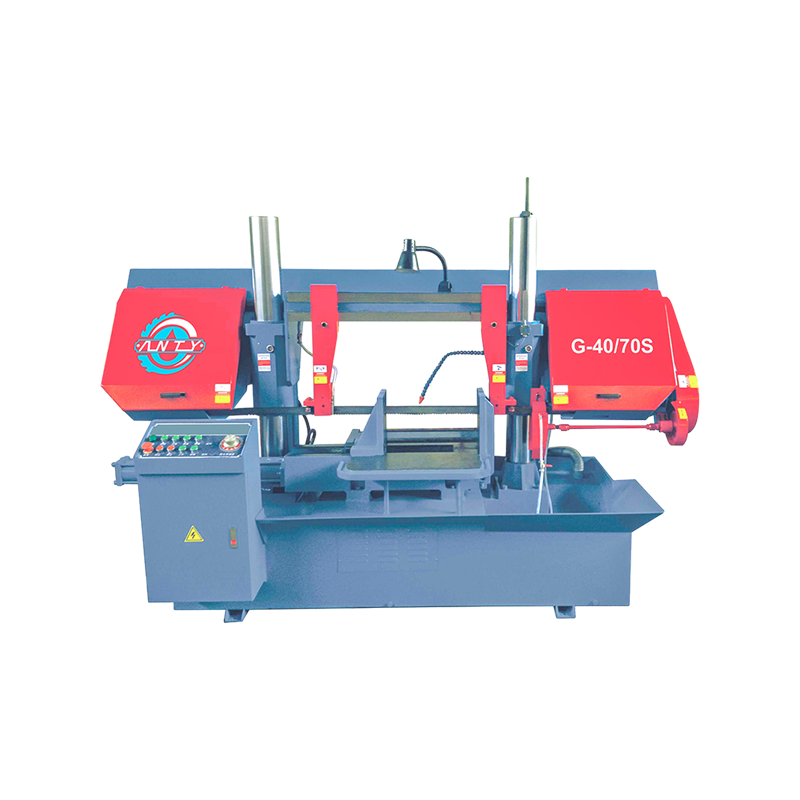

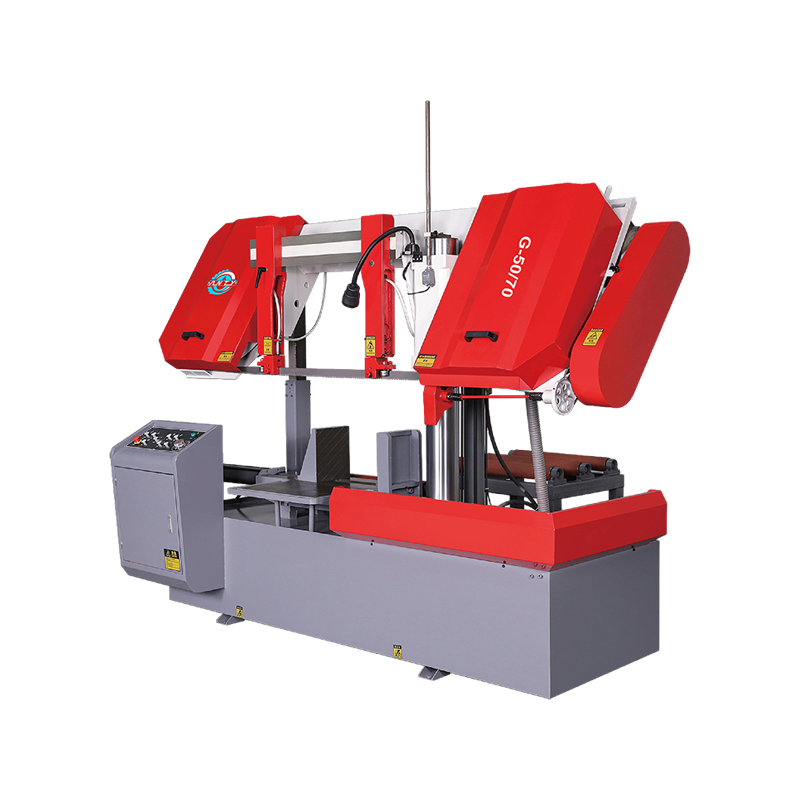

Horizontal bandsaws are designed for cutting materials while the material rests horizontally on the bed of the machine. This configuration allows for the cutting of larger, heavier workpieces with less manual effort. The cutting blade moves in a horizontal direction, cutting through the material progressively, which is ideal for cutting long, thick, or bulk materials.

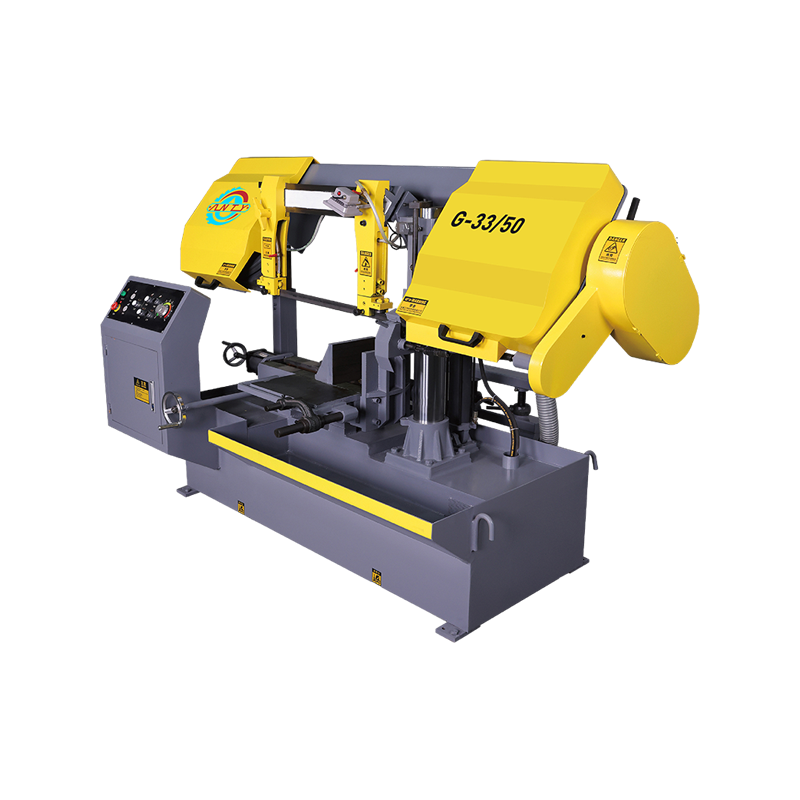

On the other hand, vertical bandsaws are designed with the material positioned vertically on the table. The blade moves in an up-and-down motion, which allows for cutting more intricate shapes, curves, and tight angles. Vertical bandsaws are typically smaller and more versatile, making them ideal for precision cutting in areas where detailed work is required, such as in the production of smaller parts, custom designs, or when high maneuverability is needed.

Precision in Material Processing

The key to the success of both horizontal and vertical bandsaws lies in their precision. Horizontal bandsaws are engineered to produce smooth, straight cuts on larger workpieces. The stationary workpiece is held securely in place, which reduces the risk of vibration or shifting during the cutting process. This is particularly important when cutting materials like steel, aluminum, and other metals, where the tolerance for error is minimal.

Meanwhile, vertical bandsaws are ideal for cutting intricate designs or complex angles that require fine detail. Because of their vertical orientation, they allow the operator to control the cutting direction more precisely, making them the preferred choice for detailed or curved cuts. Their versatility allows operators to cut through materials such as wood, plastics, and non-ferrous metals with ease, without sacrificing the level of precision needed.

Efficiency in High-Volume Production

Both horizontal and vertical bandsaws are designed to offer high cutting efficiency. Horizontal bandsaws, particularly those used in industrial applications, can handle high-volume cutting operations with little to no downtime. These machines are built for continuous operation, making them suitable for production environments where large volumes of material need to be processed quickly. Because the workpiece is securely held in place, the operator’s involvement is minimized, which reduces labor costs and improves throughput.

Vertical bandsaws, while often used for smaller-scale operations, also contribute to high-efficiency workflows. They are ideal for custom cuts and can handle multiple jobs simultaneously. Their compact design and versatile capabilities make them an essential tool in shops where space is limited but a wide range of cutting tasks is needed.

Versatility Across Industries

Both horizontal and vertical bandsaws have found their place in diverse industries, proving their versatility in various applications. In metalworking, for example, horizontal bandsaws are used extensively for cutting through thick metal stock. These saws allow for cutting heavy steel pipes, beams, or solid metal blocks, which would otherwise be challenging for traditional saws or other cutting methods. The ability to achieve precise cuts on these hard materials makes horizontal bandsaws indispensable in metal fabrication.

Vertical bandsaws, on the other hand, are preferred in industries where precision and versatility are paramount. Woodworking shops frequently use vertical bandsaws to cut intricate designs, curves, or arcs in wooden pieces. These machines can easily tackle small, detailed cuts with precision, making them for creating everything from custom furniture to architectural wood elements. Additionally, they can also be adapted to cut plastics, composites, and light metals, expanding their use in manufacturing and construction.

Both types of bandsaws also have applications in research and development. When testing new materials or designing prototypes, the need for high-precision cutting becomes critical. Horizontal and vertical bandsaws can be adapted to handle the small-scale, detailed work that is often required in research, providing engineers and developers with the tools they need to turn concepts into reality.

english

english Русский

Русский Español

Español Русский

Русский

CONTACT US

CONTACT US